Instruction manual

APP - 62

A

PPENDICES

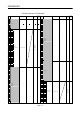

(11) Virtual servomotor axis monitor device list

Axis No. Device No. Signal name

1 D800 to D809

2 D810 to D819 Virtual

3 D820 to D829

4 D830 to D839

5 D840 to D849

Signal name Real

Roller

Ball

screw

Rotary

table

Cam

Real

mode

axis

Refresh

cycle

Fetch

cycle

Signal

direction

6 D850 to D859 0

7 D860 to D869

1

Feed current value

Operation

cycle

8 D870 to D879 2 Minor error code

9 D880 to D889 3 Major error code

Immediately

10 D890 to D899 4 Execute program No. At start

11 D900 to D909

12 D910 to D919

5 M-code

13 D920 to D929

6

14 D930 to D939

15 D940 to D949

7

Current value after virtual

servomotor axis main

shaft's differential gear

16 D950 to D959

8 Error search output axis No.

17

D960 to D969

18 D970 to D979

9

Data set pointer for

constant-speed control

Backup

Operation

cycle

Monitor

device

19 D980 to D989 : Valid, : Invalid

20 D990 to D999

21 D1000 to D1009

22 D1010 to D1019

23 D1020 to D1029

24 D1030 to D1039

25 D1040 to D1049

26 D1050 to D1059

27 D1060 to D1069

28 D1070 to D1079

29

D1080 to D1089

30 D1090 to D1099

31 D1100 to D1109

32 D1100 to D1119

POINT

(1) The range of axis No.1 to 8 is valid in the Q172DCPU.

(2) The unused axis areas in the mechanical system program can be used as an

user side.