Instruction manual

APP - 60

A

PPENDICES

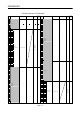

(9) Axis monitor device list

Axis No. Device No. Signal name

1 D0 to D19

2 D20 to D39 Virtual

3 D40 to D59

4 D60 to D79

5 D80 to D99

Signal name Real

Roller

Ball

screw

Rotary

table

Cam

Real

mode

axis

Refresh

cycle

Fetch

cycle

Signal

direction

6 D100 to D119 0

7 D120 to D139 1

Feed current

value/roller cycle speed

8 D140 to D159 2

9 D160 to D179 3

Real current value

10 D180 to D199 4

11 D200 to D219 5

Deviation counter value

Operation

cycle

12 D220 to D239

6 Minor error code

13 D240 to D259 7 Major error code

Immediately

14 D260 to D279

8 Servo error code

Main cycle

15 D280 to D299

16

D300 to D319

9

Home position return

re-travel value

Backup

17 D320 to D339 10

18 D340 to D359

11

Travel value after

proximity dog ON

Backup

Operation

cycle

19 D360 to D379 12 Execute program No. At start

20 D380 to D399 13 M-code

21 D400 to D419 14 Torque limit value

Operation

cycle

22 D420 to D439

23 D440 to D459

15

Data set pointer for

constant-speed control

At start/

during start

Monitor

device

24 D460 to D479 16

25 D480 to D499 17

Unusable

(Note-1)

26 D500 to D519 18

27 D520 to D539

19

Real current value at

stop input

Backup

Operation

cycle

Monitor

device

28 D540 to D559 : Valid, : Invalid

29 D560 to D579

30 D580 to D599

31 D600 to D619

32 D620 to D639

(Note-1): It can be used as the travel value change register. The travel value change register can be set to the device optionally in the servo

program.

Refer to the "Q173DCPU/Q172DCPU Motion controller (SV13/SV22) Programming Manual (REAL MODE)" for details.

POINT

(1) The range of axis No.1 to 8 is valid in the Q172DCPU.

(2) The device area more than 9 axes as an user device in the Q172DCPU.

However, when the project of Q172DCPU is replaced with Q173DCPU, this area

cannot be used.