User`s manual

Table Of Contents

- SAFETY PRECAUTIONS

- CONDITIONS OF USE FOR THE PRODUCT

- REVISIONS

- INTRODUCTION

- CONTENTS

- ABOUT MANUALS

- HOW TO USE THIS MANUAL

- ABOUT THE GENERIC TERMS AND ABBREVIATIONS

- PACKING LIST

- 1. OVERVIEW

- 2. SYSTEM CONFIGURATION

- 3. FUNCTION LIST

- 4. INSTALLATION AND UNINSTALLATION

- 5. SCREEN MAKEUP AND BASIC OPERATIONS

- 6. PROJECT CREATION

- 7. SYSTEM CHECKING FROM PERIPHERAL DEVICE

- 8. DATA SETTING

- 9. WRITING TO/READING OF/VERIFICATION OF POSITIONING MODULE DATA

- 10. POSITIONING DEBUGGING

- 11. USEFUL FUNCTIONS

- APPENDIX

- Appendix 1 Read from Module/Write to Module Reference Processing Times

- Appendix 2 Restrictions Depending on Function Version of QD75

- Appendix 3 Functions Added to/Changed from the Previous Versions

- Appendix 4 Uninstalling the License Key FD

- Appendix 5 Parameter Names Shown in GX Configurator-QP Screens and Manuals

- INDEX

11 - 24 11 - 24

MELSOFT

11. USEFUL FUNCTIONS

DISPLAY/SETTING DATA

Item Description

Flash ROM write

Select whether data will be written to flash ROM or not in the initial setting for write to

module.

• YES ......Choose Yes to make the initial setting that data will be written to flash ROM when

write to module is performed.

• NO........Choose No to make the initial setting that data will not be written to flash ROM

when write to module is performed.

Write data enable flag

When you check this check box, any changes in the test mode using positioning data test

edit or teaching are retained after the end of the test mode.

When you do not check this check box, data changes in the test mode are made invalid and

return to the previous data at the end of the test mode.

Positioning data set

Choose the range of the positioning data No. to be displayed on the positioning data edit

window.

• Data No. 1 to No. 100 .....Shows positioning data No. 1 to 100.

• Range..............................Shows positioning data No. 1 to 600.

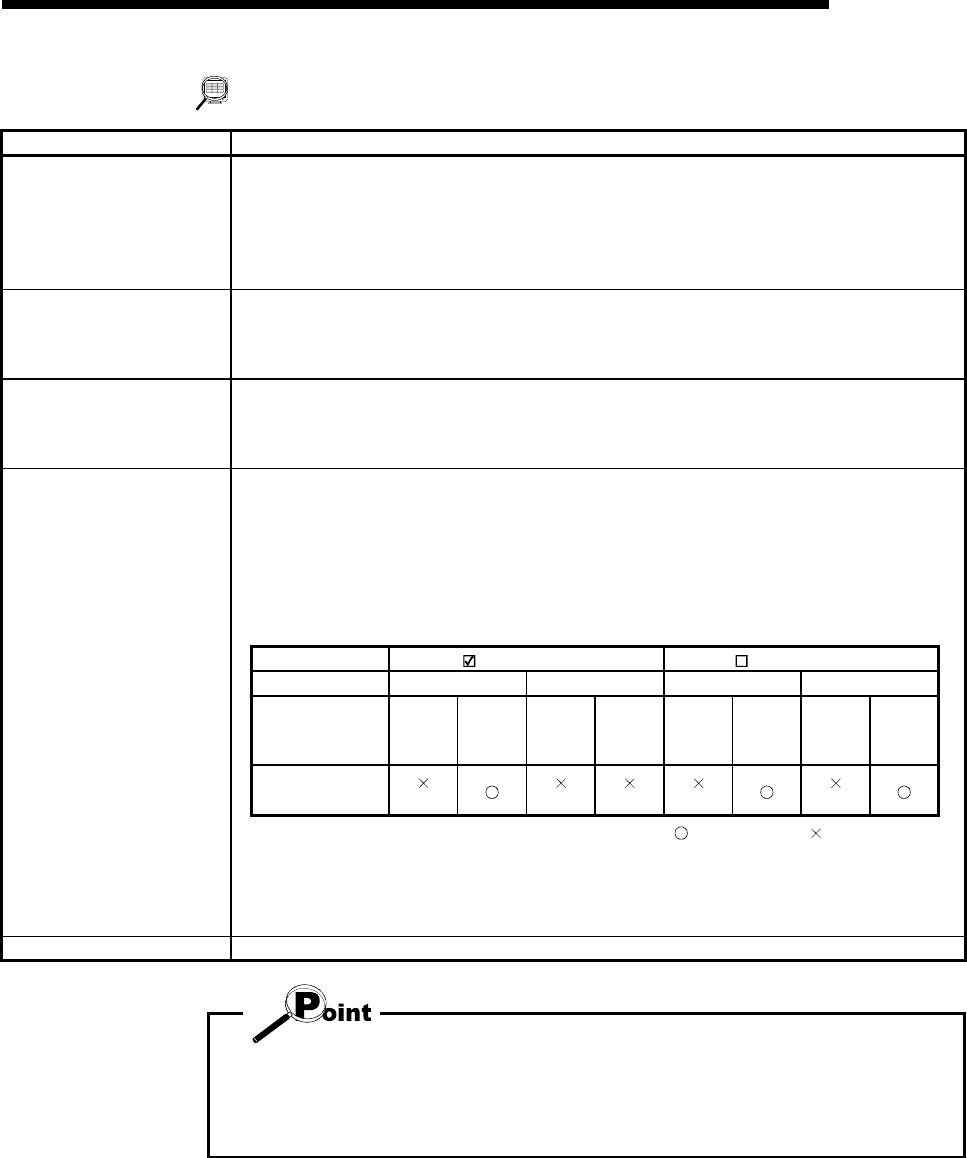

Make selection whether the programmable controller state is checked or not when write to

module, multi module batch write, flash ROM write request or QD75/LD75/LD77 initialization

is executed. (Default is "checked")

Since the set data on the Option screen is saved not on a project basis but on an application

basis, the selected set values apply to all projects.

If you do not choose PLC state check, write cannot be performed when X0

(QD75/LD75/LD77

READY signal) of the corresponding module is ON.

PLC state check PLC state check PLC state check

PLC state STOP except STOP STOP except STOP

X0 status of

corresponding

module

ON OFF ON OFF ON OFF ON OFF

Write processing

(Note 2)

(Note 1)

(Note 1)

(Note 2)

(Note 2)

PLC state check

: Write enabled : Write disabled

Note 1 : "Please make the status of PLC in to STOP or remove the check on the PLC state check on

the option screen. " appears.

Note 2 : "The QD75/LD75/LD77 READY signal is turned on. Please execute again after turning off the

QD75/LD75/LD77 READY signal." appears.

"OK" button Click this button to determine the set data.

When you increased the display range in positioning data display No. setting, it will

take longer until the positioning data edit window appears.

When positioning data No. 101 onwards are not necessary, choose data No. 1 to

No. 100. (The positioning data No. defaults to data No. 1 to No. 100.)