User`s manual

Table Of Contents

- SAFETY PRECAUTIONS

- CONDITIONS OF USE FOR THE PRODUCT

- REVISIONS

- INTRODUCTION

- CONTENTS

- ABOUT MANUALS

- HOW TO USE THIS MANUAL

- ABOUT THE GENERIC TERMS AND ABBREVIATIONS

- PACKING LIST

- 1. OVERVIEW

- 2. SYSTEM CONFIGURATION

- 3. FUNCTION LIST

- 4. INSTALLATION AND UNINSTALLATION

- 5. SCREEN MAKEUP AND BASIC OPERATIONS

- 6. PROJECT CREATION

- 7. SYSTEM CHECKING FROM PERIPHERAL DEVICE

- 8. DATA SETTING

- 9. WRITING TO/READING OF/VERIFICATION OF POSITIONING MODULE DATA

- 10. POSITIONING DEBUGGING

- 11. USEFUL FUNCTIONS

- APPENDIX

- Appendix 1 Read from Module/Write to Module Reference Processing Times

- Appendix 2 Restrictions Depending on Function Version of QD75

- Appendix 3 Functions Added to/Changed from the Previous Versions

- Appendix 4 Uninstalling the License Key FD

- Appendix 5 Parameter Names Shown in GX Configurator-QP Screens and Manuals

- INDEX

9 - 4 9 - 4

MELSOFT

9. WRITING TO/READING OF/VERIFICATION OF POSITIONING

MODULE DATA

<Verify module data>

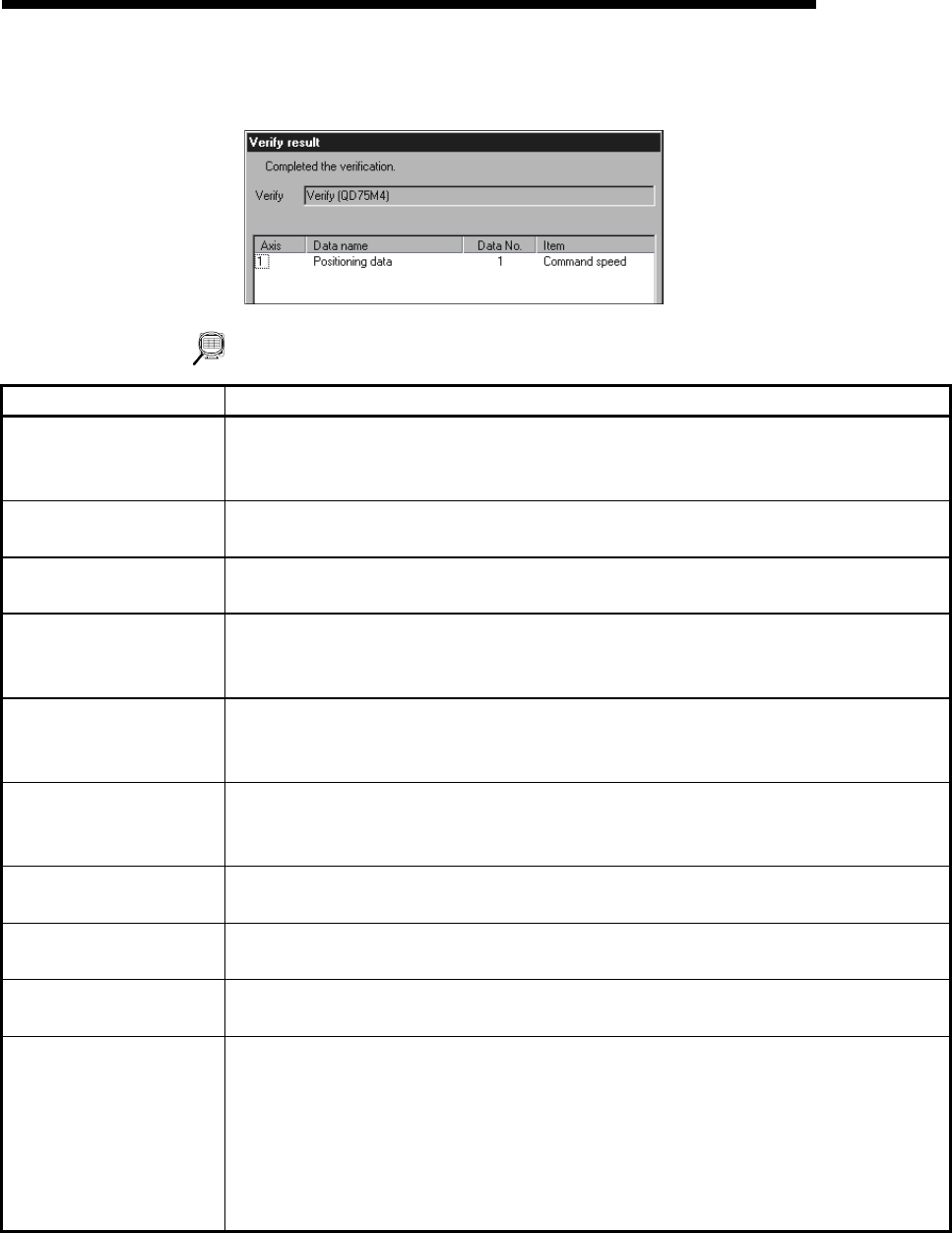

[Verify result dialog box]

DISPLAY/SETTING DATA

Item Description

Positioning data

Block start data

Parameter

Set the data used for write to QD75/LD75/LD77/read from QD75/LD75/LD77/verify

QD75/LD75/LD77 data from positioning data, block start data and parameters.

Block start data includes condition data.

"Flash ROM write" check

box

When performing write to QD75/LD75/LD77, set a request to write from buffer memory to

flash ROM at the same time.

Current type

Set the model of the QD75/LD75/LD77 connected to the peripheral device and the range of

write/read/verify.

<<Positioning data>> tab

<<Block start data>> tab

<<Parameter data>> tab

Click the corresponding tab to display the screen which is used to set the axes and ranges of

the data for write to QD75/LD75/LD77/read from QD75/LD75/LD77/verify QD75/LD75/LD77

data.

<<Positioning data>> tab

screen

Set the axes of the positioning data used for write to QD75/LD75/LD77/read from

QD75/LD75/LD77/verify QD75/LD75/LD77 data.

Also, set the positioning data No.s in the write/read/verify range on an axis by axis basis.

<<Block start data>> tab

screen

Set the axes of the block start data used for write to QD75/LD75/LD77/read from

QD75/LD75/LD77/verify QD75/LD75/LD77 data.

Also, set the range of the QD75/LD75/LD77 write/read/verify block on an axis basis.

<<Parameter data>> tab

screen

Set the axes used for write to QD75/LD75/LD77/read from QD75/LD75/LD77/verify

QD75/LD75/LD77 data.

<<Servo parameter data>>

tab screen

Set the axes used for write to QD75/LD75/LD77/read from QD75/LD75/LD77/verify

QD75/LD75/LD77 data

"OK" button

Click this button to start write to QD75/LD75/LD77/read from QD75/LD75/LD77/verify

QD75/LD75/LD77 data.

Verify result dialog box

After QD75/LD75/LD77 data verify is completed, differences between the QD75/LD75/LD77

and project appear.

The screen displays that the speed limit value of the axis #1 basic parameter 2 and the

software stroke limit upper/lower limit value of the extended parameter 1 differ between the

QD75/LD75/LD77 and project.

If there are more than 100 mismatches, verify processing is suspended as soon as the

number of mismatches reaches 100.