User`s manual

Table Of Contents

- SAFETY PRECAUTIONS

- CONDITIONS OF USE FOR THE PRODUCT

- REVISIONS

- INTRODUCTION

- CONTENTS

- ABOUT MANUALS

- HOW TO USE THIS MANUAL

- ABOUT THE GENERIC TERMS AND ABBREVIATIONS

- PACKING LIST

- 1. OVERVIEW

- 2. SYSTEM CONFIGURATION

- 3. FUNCTION LIST

- 4. INSTALLATION AND UNINSTALLATION

- 5. SCREEN MAKEUP AND BASIC OPERATIONS

- 6. PROJECT CREATION

- 7. SYSTEM CHECKING FROM PERIPHERAL DEVICE

- 8. DATA SETTING

- 9. WRITING TO/READING OF/VERIFICATION OF POSITIONING MODULE DATA

- 10. POSITIONING DEBUGGING

- 11. USEFUL FUNCTIONS

- APPENDIX

- Appendix 1 Read from Module/Write to Module Reference Processing Times

- Appendix 2 Restrictions Depending on Function Version of QD75

- Appendix 3 Functions Added to/Changed from the Previous Versions

- Appendix 4 Uninstalling the License Key FD

- Appendix 5 Parameter Names Shown in GX Configurator-QP Screens and Manuals

- INDEX

8 - 16 8 - 16

MELSOFT

8. DATA SETTING

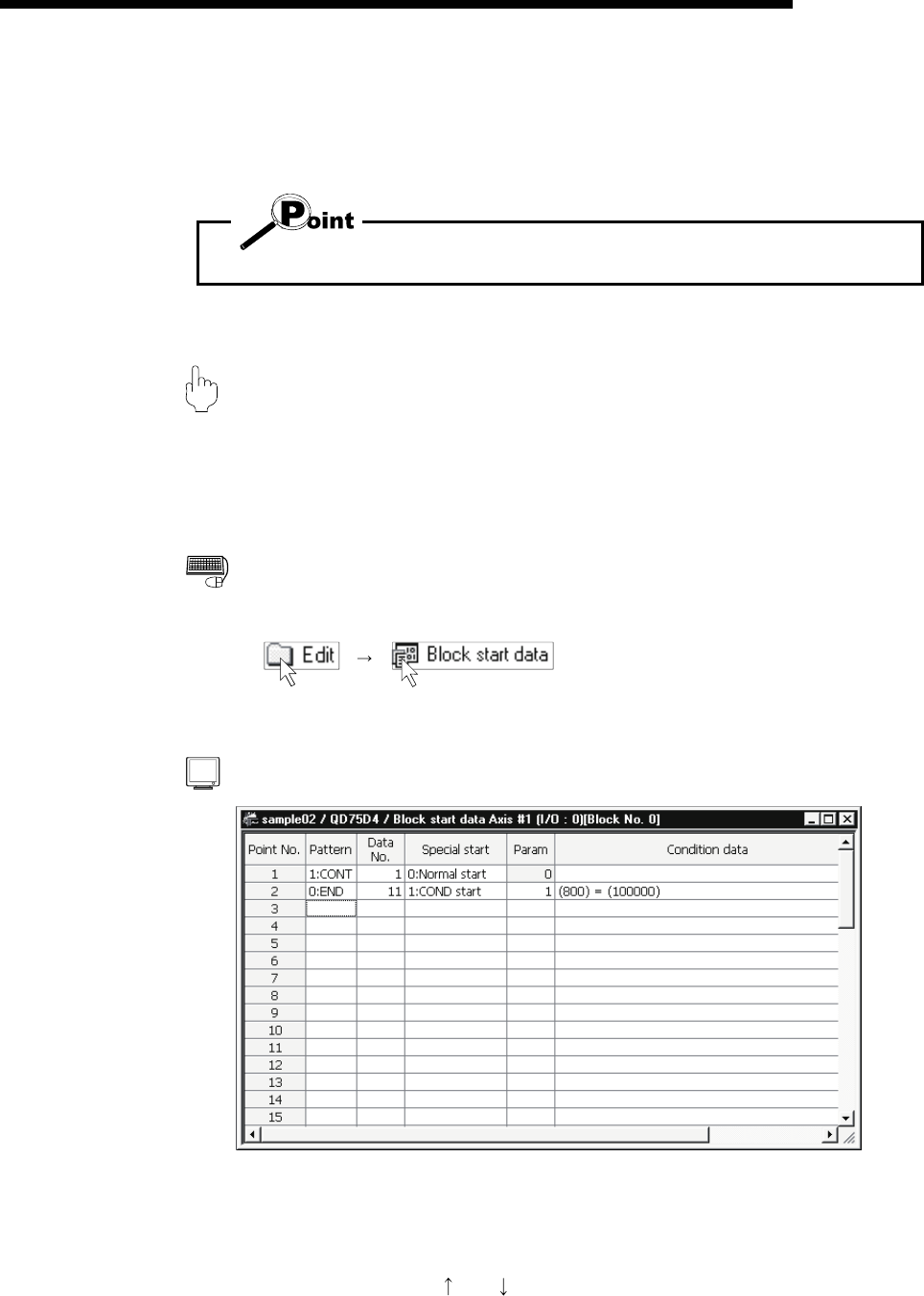

8.5 Block Start Data Setting

Set the block start data for controlling a positioning start and the condition data used as

a condition for a special start.

The block start data is equivalent to the start block data of the AD75.

8.5.1 Block start data

PURPOS

E

Specify the positioning data No. as a point, and set the block start data which sets

the starting condition, execution order and execution count to each point.

You can set up to 50 points per block.

There are blocks No. 0 to 4 per axis.

BASIC OPERATIO

N

1. Choose the block start data.

Double-click. Double-click.

2. Make settings in the block start data edit window.

DISPLAY/SETTING SCREE

N

Double-click the cell and make settings in the text box or list box.

When performing operation from the keyboard, enter the value and press the

"Enter" key to determine the value.

For "Pattern" and "Special start", press the "space" key to display a list.

Make selection with the "

" or " " key, and press the "Enter" key to determine the

value.