Car Amplifier User Manual

Table Of Contents

- Safety Instructions

- COMPLIANCE WITH EC DIRECTIVES

- CONFORMANCE WITH UL/C-UL STANDARD

- <

> - CONTENTS

- Optional Servo Motor Instruction Manual CONTENTS

- 1. FUNCTIONS AND CONFIGURATION

- 2. INSTALLATION

- 3. SIGNALS AND WIRING

- 3.1 Standard connection example

- 3.2 Internal connection diagram of servo amplifier

- 3.3 I/O signals

- 3.4 Detailed description of the signals

- 3.5 Alarm occurrence timing chart

- 3.6 Interfaces

- 3.7 Input power supply circuit

- 3.8 Connection of servo amplifier and servo motor

- 3.9 Servo motor with electromagnetic brake

- 3.10 Grounding

- 3.11 Servo amplifier terminal block (TE2) wiring method

- 3.12 Instructions for the 3M connector

- 3.13 Power line circuit of the MR-J2S-11KA to MR-J2S-22KA

- 4. OPERATION

- 5. PARAMETERS

- 6. DISPLAY AND OPERATION

- 7. GENERAL GAIN ADJUSTMENT

- 8. SPECIAL ADJUSTMENT FUNCTIONS

- 9. INSPECTION

- 10. TROUBLESHOOTING

- 11. OUTLINE DIMENSION DRAWINGS

- 12. CHARACTERISTICS

- 13. OPTIONS AND AUXILIARY EQUIPMENT

- 13.1 Options

- 13.1.1 Regenerative brake options

- 13.1.2 Brake unit

- 13.1.3 Power regeneration converter

- 13.1.4 External dynamic brake

- 13.1.5 Cables and connectors

- 13.1.6 Junction terminal block (MR-TB20)

- 13.1.7 Maintenance junction card (MR-J2CN3TM)

- 13.1.8 Battery (MR-BAT, A6BAT)

- 13.1.9 MR Configurator (Servo configurations software)

- 13.1.10 Power regeneration common converter

- 13.1.11 Heat sink outside mounting attachment (MR-JACN)

- 13.2 Auxiliary equipment

- 13.2.1 Recommended wires

- 13.2.2 No-fuse breakers, fuses, magnetic contactors

- 13.2.3 Power factor improving reactors

- 13.2.4 Power factor improving DC reactors

- 13.2.5 Relays

- 13.2.6 Surge absorbers

- 13.2.7 Noise reduction techniques

- 13.2.8 Leakage current breaker

- 13.2.9 EMC filter

- 13.2.10 Setting potentiometers for analog inputs

- 13.1 Options

- 14. COMMUNICATION FUNCTIONS

- 14.1 Configuration

- 14.2 Communication specifications

- 14.3 Protocol

- 14.4 Character codes

- 14.5 Error codes

- 14.6 Checksum

- 14.7 Time-out operation

- 14.8 Retry operation

- 14.9 Initialization

- 14.10 Communication procedure example

- 14.11 Command and data No. list

- 14.12 Detailed explanations of commands

- 14.12.1 Data processing

- 14.12.2 Status display

- 14.12.3 Parameter

- 14.12.4 External I/O pin statuses (DIO diagnosis)

- 14.12.5 Disable/enable of external I/O signals (DIO)

- 14.12.6 External input signal ON/OFF (test operation)

- 14.12.7 Test operation mode

- 14.12.8 Output signal pin ON/OFF output signal (DO) forced output

- 14.12.9 Alarm history

- 14.12.10 Current alarm

- 14.12.11 Other commands

- 15. ABSOLUTE POSITION DETECTION SYSTEM

- 15.1 Outline

- 15.2 Specifications

- 15.3 Battery installation procedure

- 15.4 Standard connection diagram

- 15.5 Signal explanation

- 15.6 Startup procedure

- 15.7 Absolute position data transfer protocol

- 15.8 Examples of use

- 15.9 Confirmation of absolute position detection data

- 15.10 Absolute position data transfer errors

- Appendix

- REVISIONS

13 - 8

13. OPTIONS AND AUXILIARY EQUIPMENT

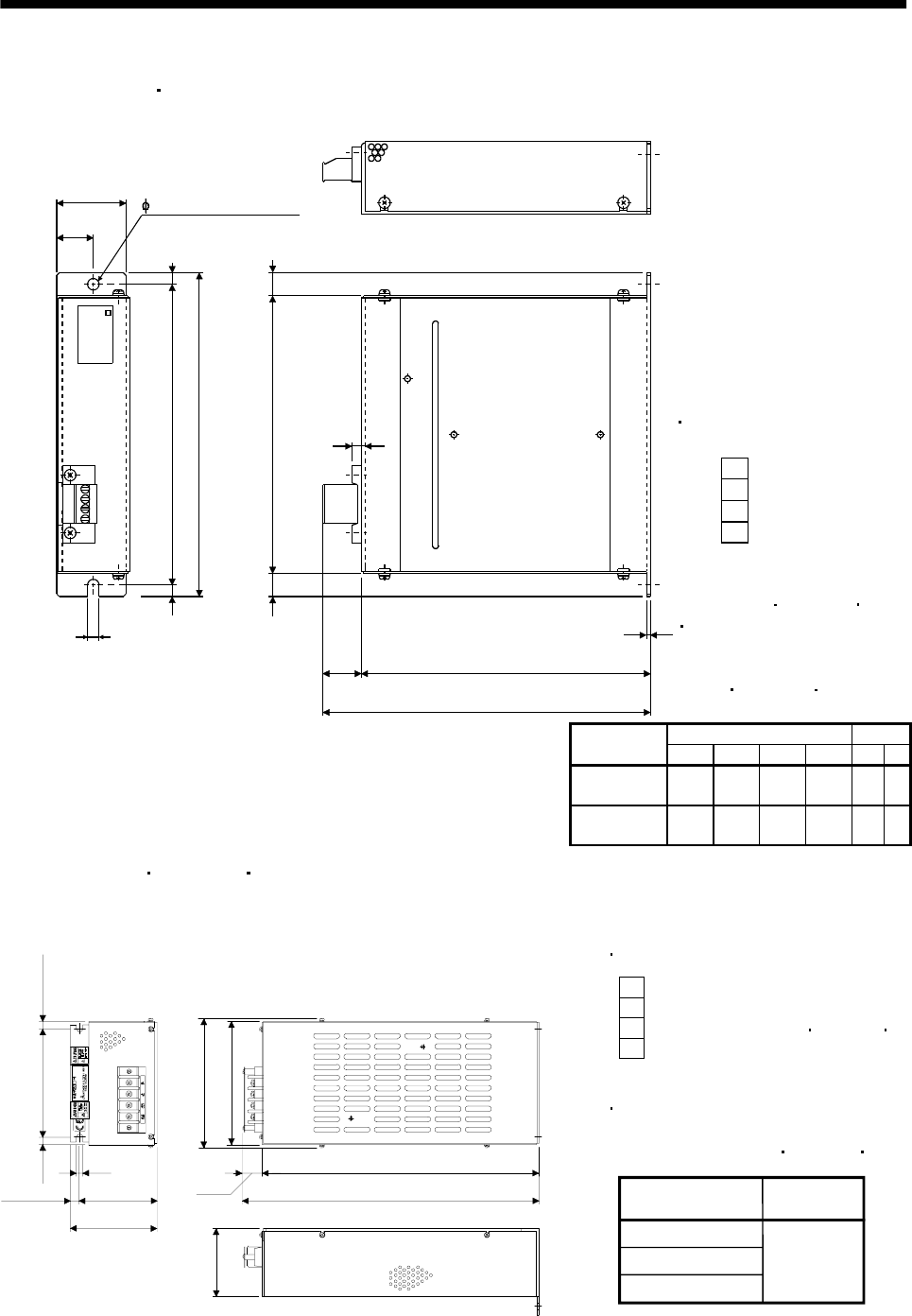

(5) Outline drawing

(a) MR-RB032

MR-RB12

LA

5 (0.20)

LB

TE1

6 (0.23)

6 (0.23)

156 (6.14)

168 (6.61)

144 (5.67)

12 (0.47)

6 (0.23)

12 (0.47)

20

(0.79)

LD

1.6 (0.06)

LC

G3

G4

P

C

[Unit: mm (in)]

6 (0.24) mounting hole

MR-RB

TE1

Terminal block

G4

G3

C

P

Terminal screw: M3

Tightening torque:

3.2 [N m](28.32 [lb in])

Mounting screw

Screw size: M5

Tightening torque:

0.5 to 0.6 [N m](4 to 5 [lb in])

Variable dimensions Mass

Regenerative

brake option

LA LB LC LD [kg] [lb]

MR-RB032

30

(1.18)

15

(0.59)

119

(4.69)

99

(3.9)

0.5 1.1

MR-RB12

40

(1.57)

15

(0.59)

169

(6.69)

149

(5.87)

1.1 2.4

(b) MR-RB30 MR-RB31 MR-RB32

Mounting screw

G4

G3

C

P

Terminal screw: M4

Tightening torque: 1.2 [N m] (10.6 [lb in])

100 (3.94)

90 (3.54)

10 (0.39)

7

8.5

(0.34)

8.5 (0.34)

125 (4.92)

150 (5.91)

142 (5.59)

17

(0.67)

318 (12.52)

335 (13.19)

79 (7.05)

G4 G3 C P

[Unit: mm (in)]

Terminal block

Tightening torque: 5.4 [N m](47.79 [lb in])

Regenerative

brake option

MR-RB30

MR-RB32

MR-RB31

2.9 (6.4)

Mass [kg] (lb)

Screw : M6