Car Amplifier User Manual

Table Of Contents

- Safety Instructions

- COMPLIANCE WITH EC DIRECTIVES

- CONFORMANCE WITH UL/C-UL STANDARD

- <

> - CONTENTS

- Optional Servo Motor Instruction Manual CONTENTS

- 1. FUNCTIONS AND CONFIGURATION

- 2. INSTALLATION

- 3. SIGNALS AND WIRING

- 3.1 Standard connection example

- 3.2 Internal connection diagram of servo amplifier

- 3.3 I/O signals

- 3.4 Detailed description of the signals

- 3.5 Alarm occurrence timing chart

- 3.6 Interfaces

- 3.7 Input power supply circuit

- 3.8 Connection of servo amplifier and servo motor

- 3.9 Servo motor with electromagnetic brake

- 3.10 Grounding

- 3.11 Servo amplifier terminal block (TE2) wiring method

- 3.12 Instructions for the 3M connector

- 3.13 Power line circuit of the MR-J2S-11KA to MR-J2S-22KA

- 4. OPERATION

- 5. PARAMETERS

- 6. DISPLAY AND OPERATION

- 7. GENERAL GAIN ADJUSTMENT

- 8. SPECIAL ADJUSTMENT FUNCTIONS

- 9. INSPECTION

- 10. TROUBLESHOOTING

- 11. OUTLINE DIMENSION DRAWINGS

- 12. CHARACTERISTICS

- 13. OPTIONS AND AUXILIARY EQUIPMENT

- 13.1 Options

- 13.1.1 Regenerative brake options

- 13.1.2 Brake unit

- 13.1.3 Power regeneration converter

- 13.1.4 External dynamic brake

- 13.1.5 Cables and connectors

- 13.1.6 Junction terminal block (MR-TB20)

- 13.1.7 Maintenance junction card (MR-J2CN3TM)

- 13.1.8 Battery (MR-BAT, A6BAT)

- 13.1.9 MR Configurator (Servo configurations software)

- 13.1.10 Power regeneration common converter

- 13.1.11 Heat sink outside mounting attachment (MR-JACN)

- 13.2 Auxiliary equipment

- 13.2.1 Recommended wires

- 13.2.2 No-fuse breakers, fuses, magnetic contactors

- 13.2.3 Power factor improving reactors

- 13.2.4 Power factor improving DC reactors

- 13.2.5 Relays

- 13.2.6 Surge absorbers

- 13.2.7 Noise reduction techniques

- 13.2.8 Leakage current breaker

- 13.2.9 EMC filter

- 13.2.10 Setting potentiometers for analog inputs

- 13.1 Options

- 14. COMMUNICATION FUNCTIONS

- 14.1 Configuration

- 14.2 Communication specifications

- 14.3 Protocol

- 14.4 Character codes

- 14.5 Error codes

- 14.6 Checksum

- 14.7 Time-out operation

- 14.8 Retry operation

- 14.9 Initialization

- 14.10 Communication procedure example

- 14.11 Command and data No. list

- 14.12 Detailed explanations of commands

- 14.12.1 Data processing

- 14.12.2 Status display

- 14.12.3 Parameter

- 14.12.4 External I/O pin statuses (DIO diagnosis)

- 14.12.5 Disable/enable of external I/O signals (DIO)

- 14.12.6 External input signal ON/OFF (test operation)

- 14.12.7 Test operation mode

- 14.12.8 Output signal pin ON/OFF output signal (DO) forced output

- 14.12.9 Alarm history

- 14.12.10 Current alarm

- 14.12.11 Other commands

- 15. ABSOLUTE POSITION DETECTION SYSTEM

- 15.1 Outline

- 15.2 Specifications

- 15.3 Battery installation procedure

- 15.4 Standard connection diagram

- 15.5 Signal explanation

- 15.6 Startup procedure

- 15.7 Absolute position data transfer protocol

- 15.8 Examples of use

- 15.9 Confirmation of absolute position detection data

- 15.10 Absolute position data transfer errors

- Appendix

- REVISIONS

12 - 1

12. CHARACTERISTICS

12. CHARACTERISTICS

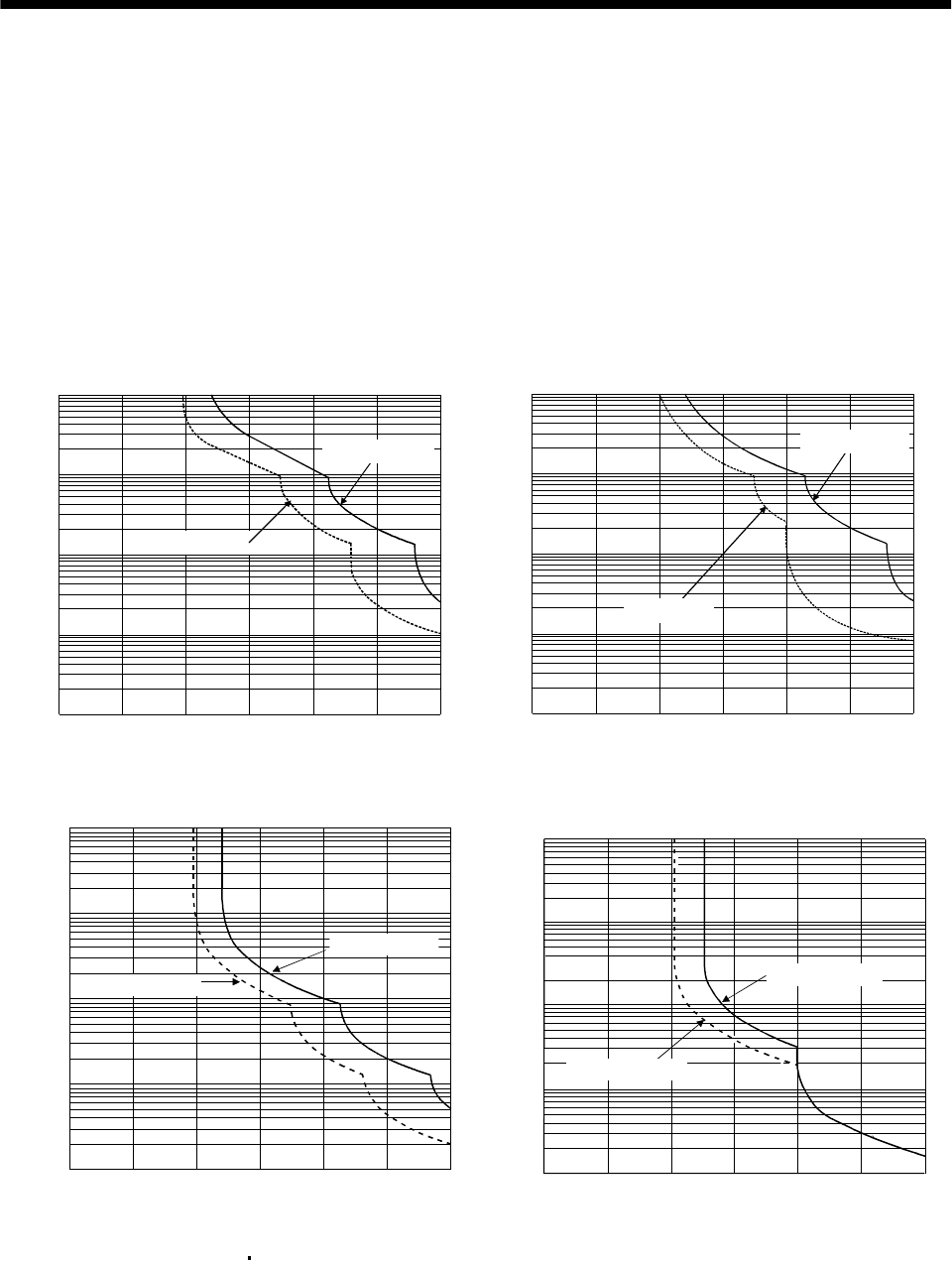

12.1 Overload protection characteristics

An electronic thermal relay is built in the servo amplifier to protect the servo motor and servo amplifier

from overloads. Overload 1 alarm (AL.50) occurs if overload operation performed is above the electronic

thermal relay protection curve shown in any of Figs 12.1. Overload 2 alarm (AL.51) occurs if the

maximum current flew continuously for several seconds due to machine collision, etc. Use the equipment

on the left-hand side area of the continuous or broken line in the graph.

In a machine like the one for vertical lift application where unbalanced torque will be produced, it is

recommended to use the machine so that the unbalanced torque is 70% or less of the rated torque.

1000

100

10

1

0.1

0 50 150 200 250 300

(Note) Load ratio [%]

Operation time[s]

During rotation

During stop

100

a. MR-J2S-10A to MR-J2S-100A

1000

100

10

1

0.1

0 50 100 150 200 250 300

(Note) Load ratio [%]

Operation time [s]

During rotation

During stop

b. MR-J2S-200A to MR-J2S-350A

0 50 100 150 200 250 300

1

10

100

1000

10000

(Note) Load ratio [%]

Operation time[s]

During rotation

During servo lock

c. MR-J2S-500A MR-J2S-700A

10000

1000

100

10

1

0 100 200 30

0

Operation time[s]

(Note) Load ratio [%]

During rotation

During servo lock

d. MR-J2S-11KA to MR-J2S-22KA

Note. If operation that generates torque more than 100% of the rating is performed with an abnormally high frequency in a servo motor

stop status (servo lock status) or in a 30r/min or less low-speed operation status, the servo amplifier may fail even when the

electronic thermal relay protection is not activated.

Fig 12.1 Electronic thermal relay protection characteristics