Car Amplifier User Manual

Table Of Contents

- Safety Instructions

- COMPLIANCE WITH EC DIRECTIVES

- CONFORMANCE WITH UL/C-UL STANDARD

- <

> - CONTENTS

- Optional Servo Motor Instruction Manual CONTENTS

- 1. FUNCTIONS AND CONFIGURATION

- 2. INSTALLATION

- 3. SIGNALS AND WIRING

- 3.1 Standard connection example

- 3.2 Internal connection diagram of servo amplifier

- 3.3 I/O signals

- 3.4 Detailed description of the signals

- 3.5 Alarm occurrence timing chart

- 3.6 Interfaces

- 3.7 Input power supply circuit

- 3.8 Connection of servo amplifier and servo motor

- 3.9 Servo motor with electromagnetic brake

- 3.10 Grounding

- 3.11 Servo amplifier terminal block (TE2) wiring method

- 3.12 Instructions for the 3M connector

- 3.13 Power line circuit of the MR-J2S-11KA to MR-J2S-22KA

- 4. OPERATION

- 5. PARAMETERS

- 6. DISPLAY AND OPERATION

- 7. GENERAL GAIN ADJUSTMENT

- 8. SPECIAL ADJUSTMENT FUNCTIONS

- 9. INSPECTION

- 10. TROUBLESHOOTING

- 11. OUTLINE DIMENSION DRAWINGS

- 12. CHARACTERISTICS

- 13. OPTIONS AND AUXILIARY EQUIPMENT

- 13.1 Options

- 13.1.1 Regenerative brake options

- 13.1.2 Brake unit

- 13.1.3 Power regeneration converter

- 13.1.4 External dynamic brake

- 13.1.5 Cables and connectors

- 13.1.6 Junction terminal block (MR-TB20)

- 13.1.7 Maintenance junction card (MR-J2CN3TM)

- 13.1.8 Battery (MR-BAT, A6BAT)

- 13.1.9 MR Configurator (Servo configurations software)

- 13.1.10 Power regeneration common converter

- 13.1.11 Heat sink outside mounting attachment (MR-JACN)

- 13.2 Auxiliary equipment

- 13.2.1 Recommended wires

- 13.2.2 No-fuse breakers, fuses, magnetic contactors

- 13.2.3 Power factor improving reactors

- 13.2.4 Power factor improving DC reactors

- 13.2.5 Relays

- 13.2.6 Surge absorbers

- 13.2.7 Noise reduction techniques

- 13.2.8 Leakage current breaker

- 13.2.9 EMC filter

- 13.2.10 Setting potentiometers for analog inputs

- 13.1 Options

- 14. COMMUNICATION FUNCTIONS

- 14.1 Configuration

- 14.2 Communication specifications

- 14.3 Protocol

- 14.4 Character codes

- 14.5 Error codes

- 14.6 Checksum

- 14.7 Time-out operation

- 14.8 Retry operation

- 14.9 Initialization

- 14.10 Communication procedure example

- 14.11 Command and data No. list

- 14.12 Detailed explanations of commands

- 14.12.1 Data processing

- 14.12.2 Status display

- 14.12.3 Parameter

- 14.12.4 External I/O pin statuses (DIO diagnosis)

- 14.12.5 Disable/enable of external I/O signals (DIO)

- 14.12.6 External input signal ON/OFF (test operation)

- 14.12.7 Test operation mode

- 14.12.8 Output signal pin ON/OFF output signal (DO) forced output

- 14.12.9 Alarm history

- 14.12.10 Current alarm

- 14.12.11 Other commands

- 15. ABSOLUTE POSITION DETECTION SYSTEM

- 15.1 Outline

- 15.2 Specifications

- 15.3 Battery installation procedure

- 15.4 Standard connection diagram

- 15.5 Signal explanation

- 15.6 Startup procedure

- 15.7 Absolute position data transfer protocol

- 15.8 Examples of use

- 15.9 Confirmation of absolute position detection data

- 15.10 Absolute position data transfer errors

- Appendix

- REVISIONS

10 - 7

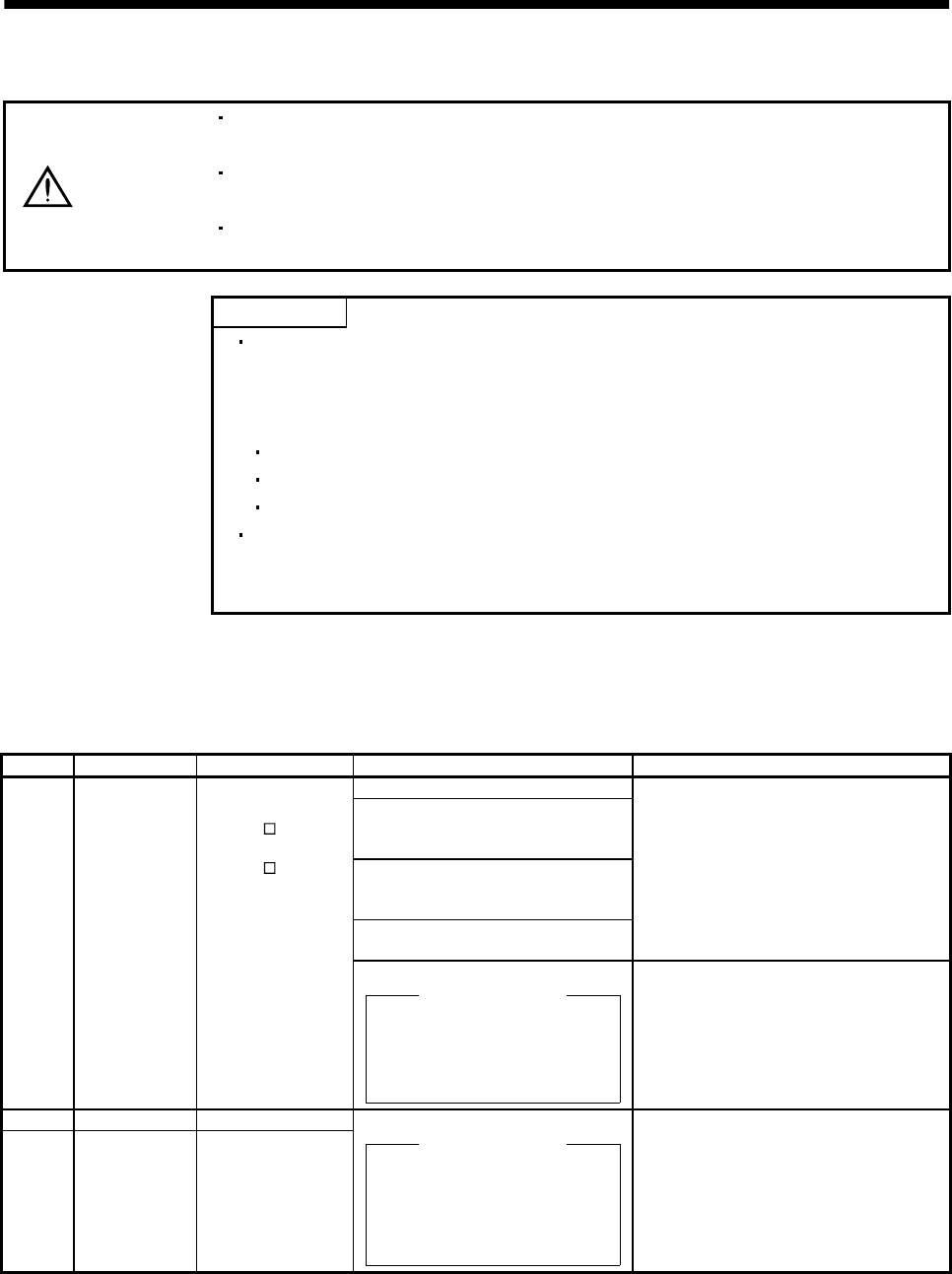

10. TROUBLESHOOTING

10.2.2 Remedies for alarms

CAUTION

When any alarm has occurred, eliminate its cause, ensure safety, then reset the

alarm, and restart operation. Otherwise, injury may occur.

If an absolute position erase (AL.25) occurred, always make home position setting

again. Otherwise, misoperation may occur.

As soon as an alarm occurs, turn off Servo-on (SON) and power off the main

circuit.

POINT

When any of the following alarms has occurred, always remove its cause

and allow about 30 minutes for cooling before resuming operation. If

operation is resumed by switching control circuit power off, then on to reset

the alarm, the servo amplifier and servo motor may become faulty.

Regenerative error (AL.30)

Overload 1 (AL.50)

Overload 2 (AL.51)

The alarm can be deactivated by switching power off, then on press the

"SET" button on the current alarm screen or by turning on the reset (RES).

For details, refer to Section 10.2.1.

When an alarm occurs, the trouble (ALM) switches off and the dynamic brake is operated to stop the

servomotor. At this time, the display indicates the alarm No.

The servo motor comes to a stop. Remove the cause of the alarm in accordance with this section. The

optional MR Configurator (servo configuration software) may be used to refer to the cause.

Display Name Definition Cause Action

1. Power supply voltage is low.

2. There was an instantaneous

control power failure of 60ms or

longer.

3. Shortage of power supply capacity

caused the power supply voltage to

drop at start, etc.

4. The bus voltage dropped to

200VDC.

Review the power supply.

AL.10 Undervoltage Power supply

voltage dropped.

MR-J2S-

A:

160VAC or less

MR-J2S-

A1:

83VAC or less

5. Faulty parts in the servo amplifier

Checking method

Alarm (AL.10) occurs if power is

switched on after disconnection

of all cables but the control

circuit power supply cables.

Change the servo amplifier.

AL.12 Memory error 1 RAM, memory fault

AL.13 Clock error Printed board fault

Faulty parts in the servo amplifier

Checking method

Alarm (any of AL.11 and AL.13)

occurs if power is switched on

after disconnection of all cables

but the control circuit power

supply cables.

Change the servo amplifier.