User manual

Table Of Contents

- Cover

- Introduction

- Precautions for Safety

- CONTENTS

- 1. Parameter Screens

- 2. Machining Parameters

- 3. I/O Parameters

- 4. Setup Parameters

- 5. Base Specifications Parameters

- 6. Axis Specifications Parameters

- 7. Servo Parameters

- 8. Spindle Parameters

- 9. Machine Error Compensation

- 10. PLC Constants

- 11. Macro List

- 12. Position Switch

- 13. Indexing Axis Parameters

- 14. Indexing Axis Position Switch

- 15. Indexing Axis Commands

- 16. Auxiliary Axis Parameters

- Revision History

- Back cover

5. Base Specifications Parameters

40

# Items Details

Setting range (unit)

1203 TmirS1

(For L

system

only)

Select

turrets for

double-turret

mirror image

with T

command

Set up turrets for double-turret mirror image with the T

command that corresponds to tool numbers 1 to 32.

0 to FFFFFFFF

1204 TmirS2

(For L

system

only)

Select

turrets for

double-turret

mirror image

with T

command

Set up turrets for double-turret mirror image with the T

command that corresponds to tool numbers 33 to 64.

0 to FFFFFFFF

1205 G0bdcc Acceleration

and

deceleration

before G0

interpolation

0: G00 acceleration and deceleration are selected as

those after interpolation regardless of

high-accuracy mode.

1: G00 acceleration and deceleration are selected as

those before interpolation.

0/1

1206 G1bF Maximum

speed

Set up a cutting feedrate when selecting acceleration

and deceleration before interpolation.

1 to 1000000

(mm/min)

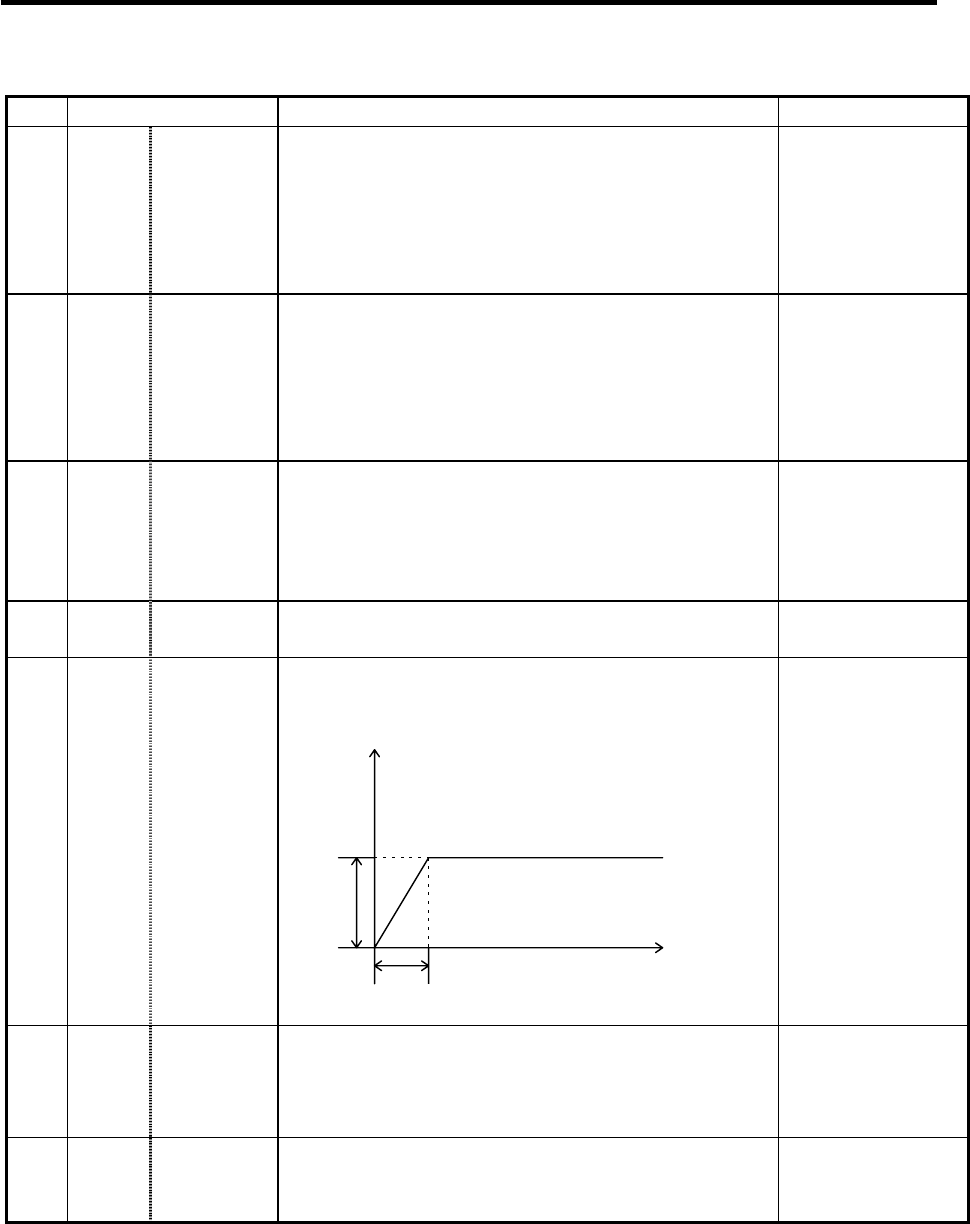

1207 G1btL Time

constant

Set up a cutting feed time constant when selecting

acceleration and deceleration before interpolation.

Speed

Time

G1bF

G1btL

1 to 5000 (ms)

1208 RCK Arc radius

error

compen-

sation factor

An arc radius error compensation amount can be

increased and decreased from −60.0 to 20.0%.

−60.0 to +20.0 (%)

1209 cirdcc Arc

deceleration

speed

Specify the deceleration speed at the arc entrance or

exit.

1 to 1000000

(mm/min)