Specifications

7

Unit Operation

1. Turn the blower on. This action will cause the

fi lter unit to activate and start cleaning fi lters.

NOTE: Some particulate may pass through the

cartridge fi lters and blower upon initial start-up.

This will end once the fi lters have been seasoned

and a power cake has formed on the fi lter. If this

condition continues to occur, refer to the section

“Roto-Pulse Cleaning Timer Adjustments” to

increase the period of time between pulses.

2. once the unit is running the Roto-Pulse cleaning

system will be operational. Operation is

detected by hearing a .07-second air pulse

approximately every 5 seconds. If adjustment

to timing of pulses is desired refer to the secion

“Roto-Pulse Cleaning Timer Adjustments”.

3. Check the After-Pulse Cleaning cycle by turning

off the unit via the stop switch located on the

side of the electrical box. The unit should

continue to pulse every 5 seconds for a period

of approximately 17 minutes. If adjustment

to the after-pulse time is desired, refer to the

section labeled “After-Pulse Cleaning”.

Cartridge Cleaning Operation

The Micro Air Dust Collector is designed with the

Roto-Pulse Cleaning System to clean the cartridge

fi lters.

This system provide superior cleaning performance

using a rotating tube with pre-drilled holes (see

Figure 8). As the diaphragm valve opens, the Roto-

Pulse tube rotates while air exits the holes, thus

providing the cleaning of the cartridge.

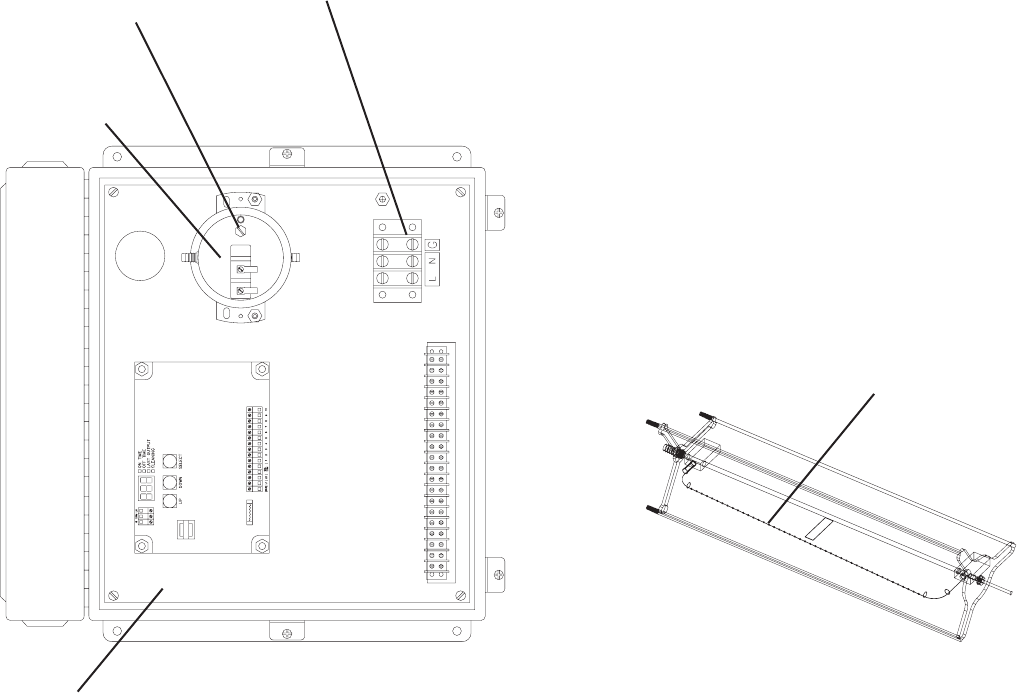

Electrical Installation

NOTE: All electrical work must be done by a

qualifi ed electrician.

CAUTION: Installation can cuase exposure to

live components. Disconnect electrical power

befor proceeding with installation. Proper lock

out/tag out procedures should be used.

1. Open the electrical box cover located on the

side of the unit. Make connections from your

120V supply power to terminal L, N and G (see

fi gure 7).

2. When supply power has been terminated,

reconnect the power. Momentarily turn the

remote blower on and adjust pressure switch

via set screw until contact is made. Use ohm

meter to measure continuity across the pressure

switch.

FIGURE 7

SET SCREW

POWER

CONNECTION

PRESSURE

SWITCH

TIMER

BOARD

FIGURE 8

ROTO-PULSE TUBE