Technical data

10

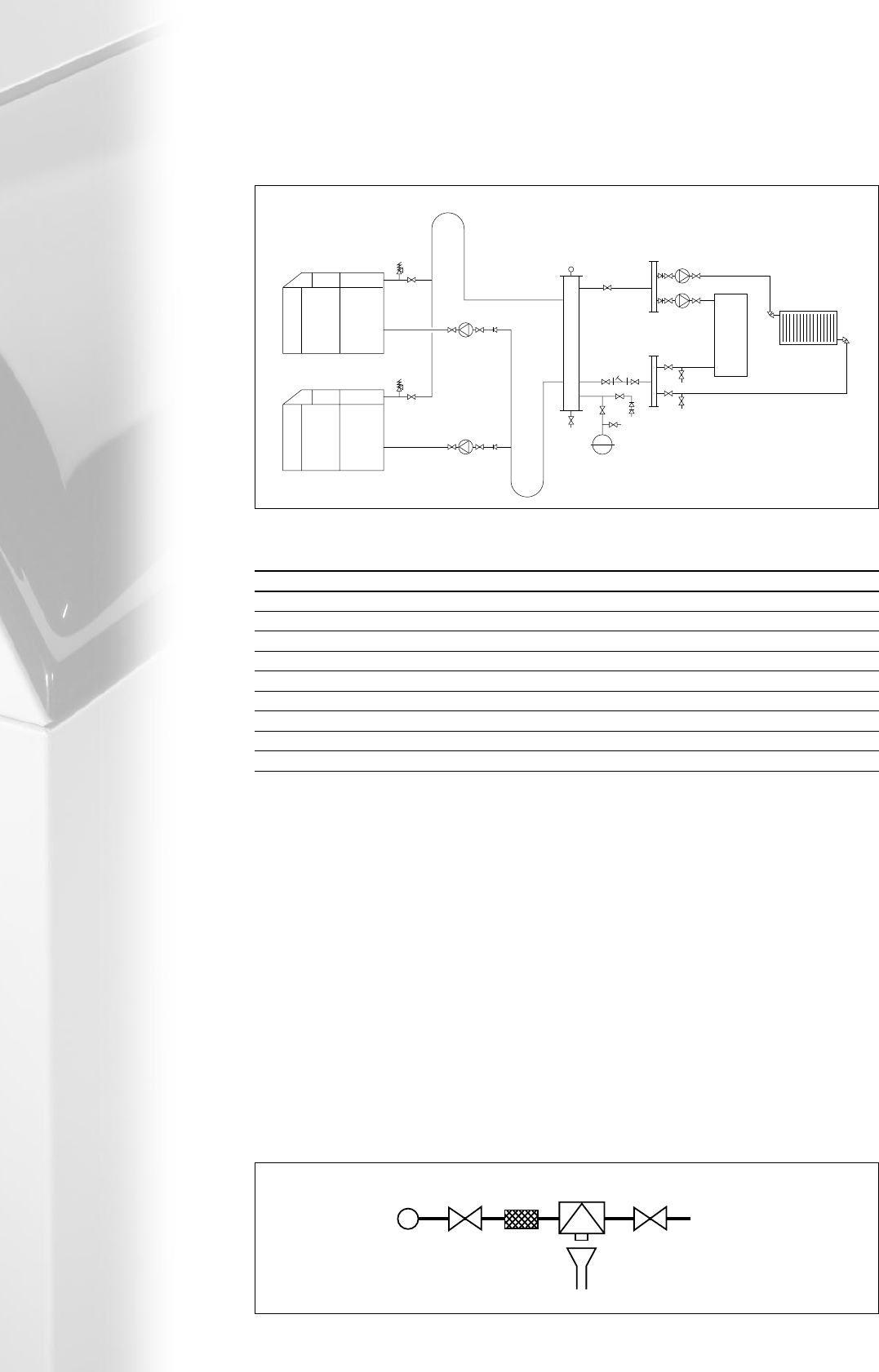

4.5 hydraulic system design (contd)

recommended system design

typical multiple Midimat HT boiler installation

Expansion Vessel

AAV

AAV

Return Header

Flow Header

Pumps

DOC

DOC

LSV

IV

IV

IV

IV

NRV

IV

DOC

DOC

SV

Strainer

Strata 3 Boiler

Strata 3 Boiler

Heating Load

IV

IV

IV

IV

IV

IV

IV IV

HWS

Load

Vertical Low

Velocity Mixing

Header

Vmax 0.5m/s

BLR Pump

IV IV

NRV

BLR Pump

SV

Fill Point*

Fig 4.5b

Boiler Power kW Diameter based upon ∆t 20°C

220 100mm

330 125mm

440 125mm

660 150mm

880 175mm

990 175mm

1100 200mm

1320 200mm

1650 225mm

Table 4 - Low velocity vertical mixing header diameter sizing guide

Tube diameters refer to medium grade or large steel tubes and are calculated using data from CIBSE guide C4

AAV

* Fill Point. In accordance with BS6644, automatic

pressurisation unit must be installed

The initial filling of a sealed heating system, and

subsequent refilling, must be by a method that has

been approved by the Water Regulation Advisory

Scheme (WRAS) for that type of heating system.

ie. Non Domestic (Other than in-House) Fluid

Category 4 (C-4). For Category 4 systems, the

approved method of filling must comprise of the

following components in the arrangement shown;

● Control valve

● Strainer

● Verifiable backflow device with reduced

pressure zone (RPZ Valve). Incorporating a

'Type BA' air gap.

● Tundish

● Control valve

Further more, in accordance with BS6644, for

boiler/s with an input greater than 60kW, an

automatic pressurisation unit must be installed to

automatically replenish any lost or evpourated water.

The pressurisation unit must comprise of the

following components;

● A cistern fitted with a float operated valve

incorporating either a 'Type AG' (C-3), or

'Type AF' (C-4) air gap.

● A presssure booster pump fitted with a single

check valve

● A pressure reducing valve

● A pressure switch

For information on a comprehensive range of

pressurisation units please contact MHS Sales.

4.6 filling the system

MCWS

CV CV

Strainer

Heating System

Tundish

RPZ