Technical data

Table Of Contents

- User Instructions for the Micromat boiler

- Product Description

- Technical Data

- Delivery Consignment / Unpacking the boiler

- Boiler location

- Installation Clearances

- Wall Mounting

- Gas Connection

- Gas Conversion

- System Flow & Return connections

- Condensate Connection

- Flue / Combustion Air connection

- Flue Systems

- Calculating Flue Resistance

- Ventilation requirements single appliances

- Hydraulic System Design

- System type 1

- System type 2

- System type 3

- System type 4

- System type 5

- System type 6

- System type 7

- System type 8

- Water Treatment

- Soldering Flux

- Electrical Connection

- System Type 1

- System Type 2

- System Type 3

- System Type 4

- System Type 5

- System Type 6

- System Type 7

- System Type 8

- Commissioning The Micromat EC

- Installation Codes

- First Firing

- Pop Up Menu

- Setting DHW Temperature

- Servicing

- Screen Display Diagnosis of Faults

48

18.3 first

firing

Notes

The MICROMAT EC boiler has a single heat exchange

and burner assembly. There is one gas valve serving

the assembly.

a) Ensure gas & electricity supplies are turned on to

the appliance.

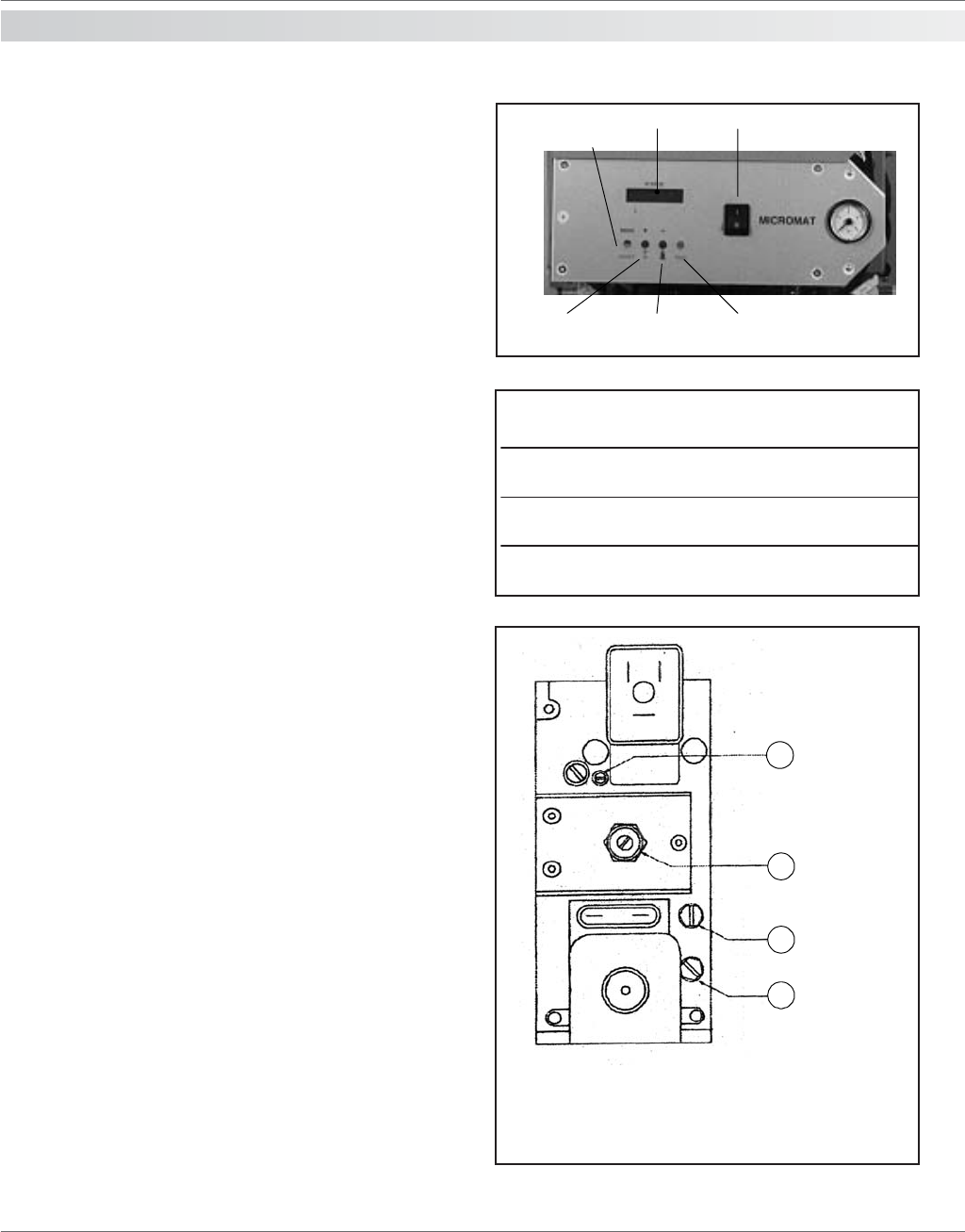

b) Switch on the boiler at the on/off switch. (See figure

to the right) The appliance will purge the combustion

chamber with air from the burner fan and then will pulse

the pumps on/off (deaerating).

c) Attach U tube manometer to inlet pressure test point

on gas valve (See figure 8). The nominal pressure

should be 20mb for NG or 37mb for LPG.

d) Press the Engineers test button twice - the screen

should/must display [10 min Low]. To reduce the burner

to its lowest firing rate press the ‘-’ key until the fan

speed reduces to its minimum revs (see section 18.5).

In the event that ignition of the burner does not occur

after 4 attempts the appliance will go to ignition failure

lockout. Remove the cover cap screws from Qmin

adjustment on gas valve (See figure 8(3)) turn

adjustment screw half turn clockwise.

Press reset button, appliance will post purge and vent

again.

Press Engineers test button twice to reset appliance to

“I0 min Low” and ignition sequence will start again. If

ignition fails again after 4 attempts, then further increase

Qmin on gas valve by half turn until burner ignites.

e) Observe the colour of burner flame - correct colour

should be dull red. Adjust colour of burner flame using

Qmin until flame colour is correct. Following this

procedure will avoid poisoning your combustion

analyser.

f)Remove flue gas analysis test point cap or plug (from

top right of combustion chamber) of the heat exchanger

and insert probe of combustion analyser Adjust as

necessary Qmin of valve to obtain required C02% value.

(See table 2) Make adjustments slowly and wait at least

2 minutes for reading to stabilise before re-adjusting.

Remove analyser and refit cap/plug to test point.

NOTE: Test period expires after 10 minutes - if this

expires whilst commissioning is still in progress, press

Engineers button twice to reset and carry on with

necessary checks and adjustments. To exit “10 min Low’

test period - press Engineers button once, this will set

controls to auto.

g)Press the ‘+’ button until the fan is at its maximum

rate (see section 18.5) This will set the burner to

maximum output.

Display ON/Off switch

Menu/Reset

Button

Summer/Winter

and “+” button

Test button

Engineers

and “-” button

4

3

2

1

Q max

Q min

Burner offset

pressure test

point

Gas inlet

pressure test

point

Adjustments

Turning 3 clockwise increases min output & CO2%

Turning 4 clockwise increase max output & CO2%

epytsaG02GsaGtaN13GGPL

tuptuOniMta%2OC5.9-921-11

tuptuOxaMta%2OC2.9-7.811-01

Flue Gas CO

2

% Settings

Figure 8