Technical data

Table Of Contents

- User Instructions for the Micromat boiler

- Product Description

- Technical Data

- Delivery Consignment / Unpacking the boiler

- Boiler location

- Installation Clearances

- Wall Mounting

- Gas Connection

- Gas Conversion

- System Flow & Return connections

- Condensate Connection

- Flue / Combustion Air connection

- Flue Systems

- Calculating Flue Resistance

- Ventilation requirements single appliances

- Hydraulic System Design

- System type 1

- System type 2

- System type 3

- System type 4

- System type 5

- System type 6

- System type 7

- System type 8

- Water Treatment

- Soldering Flux

- Electrical Connection

- System Type 1

- System Type 2

- System Type 3

- System Type 4

- System Type 5

- System Type 6

- System Type 7

- System Type 8

- Commissioning The Micromat EC

- Installation Codes

- First Firing

- Pop Up Menu

- Setting DHW Temperature

- Servicing

- Screen Display Diagnosis of Faults

Energy Technology

Ltd.

41

17.0 electrical

connections

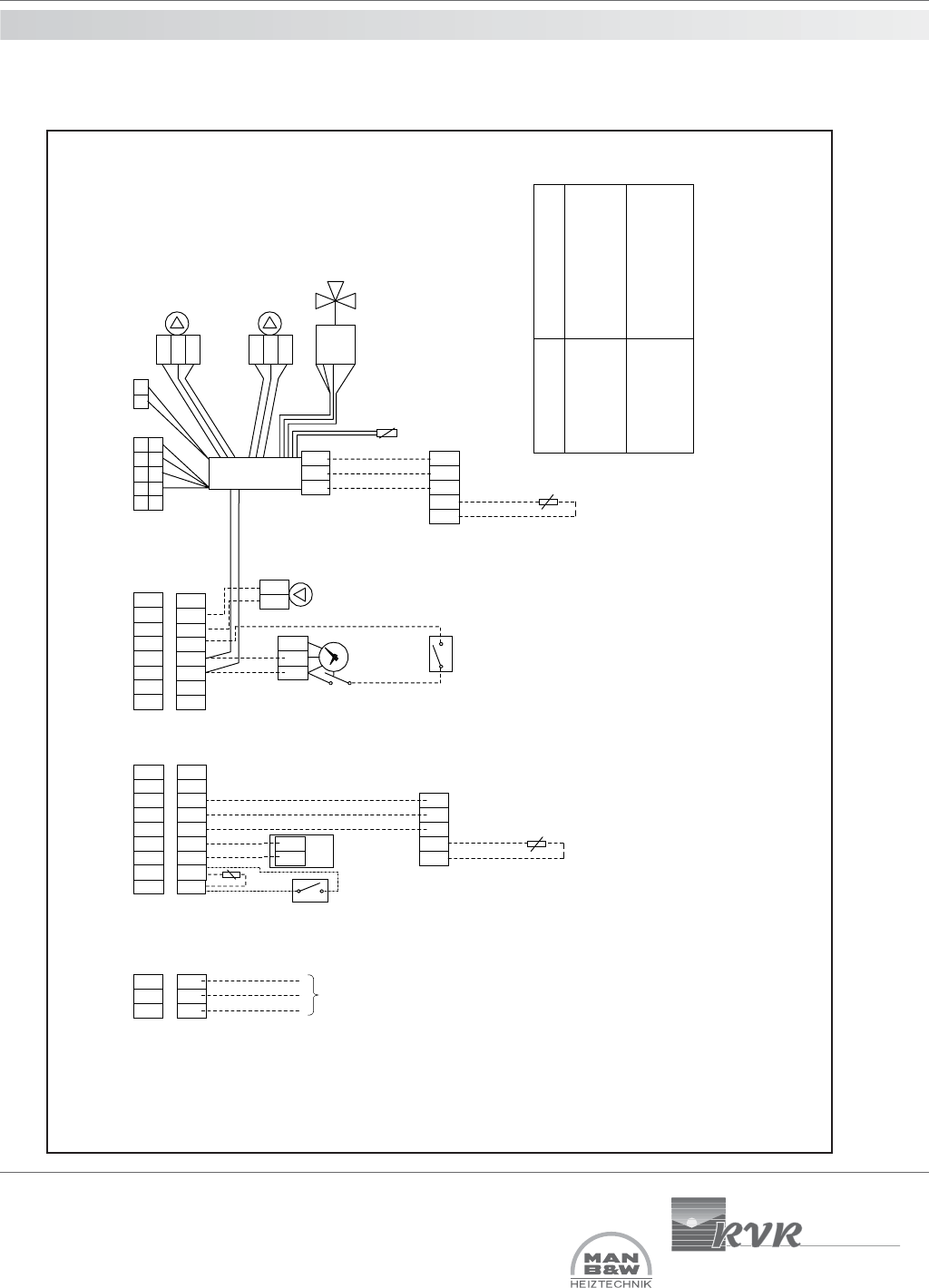

Typical electrical connection schematic to suit system type 7

MRO 3

Install only if direct-on-boiler weather

compensated flow temperature are

required.

Install only one method of external time and

room temperature control. If room and stat

time switch are required, then do not install

RE2132 room unit and vice versa.

*

**

X3

10

5

6

1

21

upper terminal strip

L1

PE

N

L1

N

L2

Supply

230V

Room Thermostat

And Time Switch

**

3

4

R1

R2

R3

1 2

O S

4 3 2 5 1

* Outside

Air Sensor

RE2132

Modulating

Room unit

**

QAW44

optional

Remote Sensor

GND

PMW

+24V

1

2

5

6

2 pin plug on X4

L1

N

L1

N

lower terminal strip

HWS

sensor

cylinder

thermostat

***

X16

L

N

Install only one method of HWS temperature

control. The use of an HWS sensor will allow

no time control over hot water production.

If timed hot water control is required then do

not install an HWS sensor, but install only

timeswitch & cylinder thermostat.

***

On LPG installations where an additional gas

safety shut off valve is required, connect to L1 and

N terminals on left side of lower terminal strip.

L

PE

N

Underfloor Zone VT

Pump 2A Max

NOTE: All Connections into

MRO 3 are made via

labelled factory fitted

Cables with the exception

of the underfloor zone

RE2132 which is cabled by

the installer

R4

R5

R6

Radiator Zone Pump

2A Max

L

PE

N

4 3 2 5 1

RE2132

Modulating

Room unit for

underfloor zone

GND

PMW

+24V

Underfloor Zone

VT Flow Sensor

L1

N

L2

Underfloor Zone VT

Mixing Valve

Installation code

Outside sensor installed.

MR03 mixing valve

controller and 2 x RE2132

installed

No outside sensor. MR03

mixing valve controller

and 2 x RE2132 installed

11

25

Description