Technical data

Table Of Contents

- User Instructions for the Micromat boiler

- Product Description

- Technical Data

- Delivery Consignment / Unpacking the boiler

- Boiler location

- Installation Clearances

- Wall Mounting

- Gas Connection

- Gas Conversion

- System Flow & Return connections

- Condensate Connection

- Flue / Combustion Air connection

- Flue Systems

- Calculating Flue Resistance

- Ventilation requirements single appliances

- Hydraulic System Design

- System type 1

- System type 2

- System type 3

- System type 4

- System type 5

- System type 6

- System type 7

- System type 8

- Water Treatment

- Soldering Flux

- Electrical Connection

- System Type 1

- System Type 2

- System Type 3

- System Type 4

- System Type 5

- System Type 6

- System Type 7

- System Type 8

- Commissioning The Micromat EC

- Installation Codes

- First Firing

- Pop Up Menu

- Setting DHW Temperature

- Servicing

- Screen Display Diagnosis of Faults

Energy Technology

Ltd.

33

16.1 water treatment

system cleaning

The entire system must be thoroughly cleansed and flushed to remove debris, flux residues etc before opening the

boiler isolation valves & flooding the boiler. Particular care must be taken where the MICROMAT EC boiler is being

retro-fitted into an old/existing system, as system silt or magenite can be very damaging to the new boiler.

The system must be filled with clean chemically neutral water. Water hardness must not exceed 3.6 mol/m

3

(=20°dH).

Chloride Concentrations must not exceed 150mg/l.

Following cleansing and flushing, the system must be dosed with a good quality water treatment to prevent corrosion

and the formation of scale. A suitable corrosion inhibitor ‘INIBAL’ is available from RVR Limited and should be used

in all systems. The required concentration is 1-2% of system capacity.

Failure to observe these requirements will render the guarantee on the product void.

Cleansing, flushing and water treatment must be carried out in accordance with the requirements of BS 7593:1992.

16.2 care with the use of

soldering flux

The MICROMAT EC boiler has heat exchangers fabricated from 316L stainless steel. It is most important that the

compatibility of any flux is checked with the flux supplier before use, and that any flux manufacturers recommendations

are strictly followed with regards to use in conjunction with stainless steel.

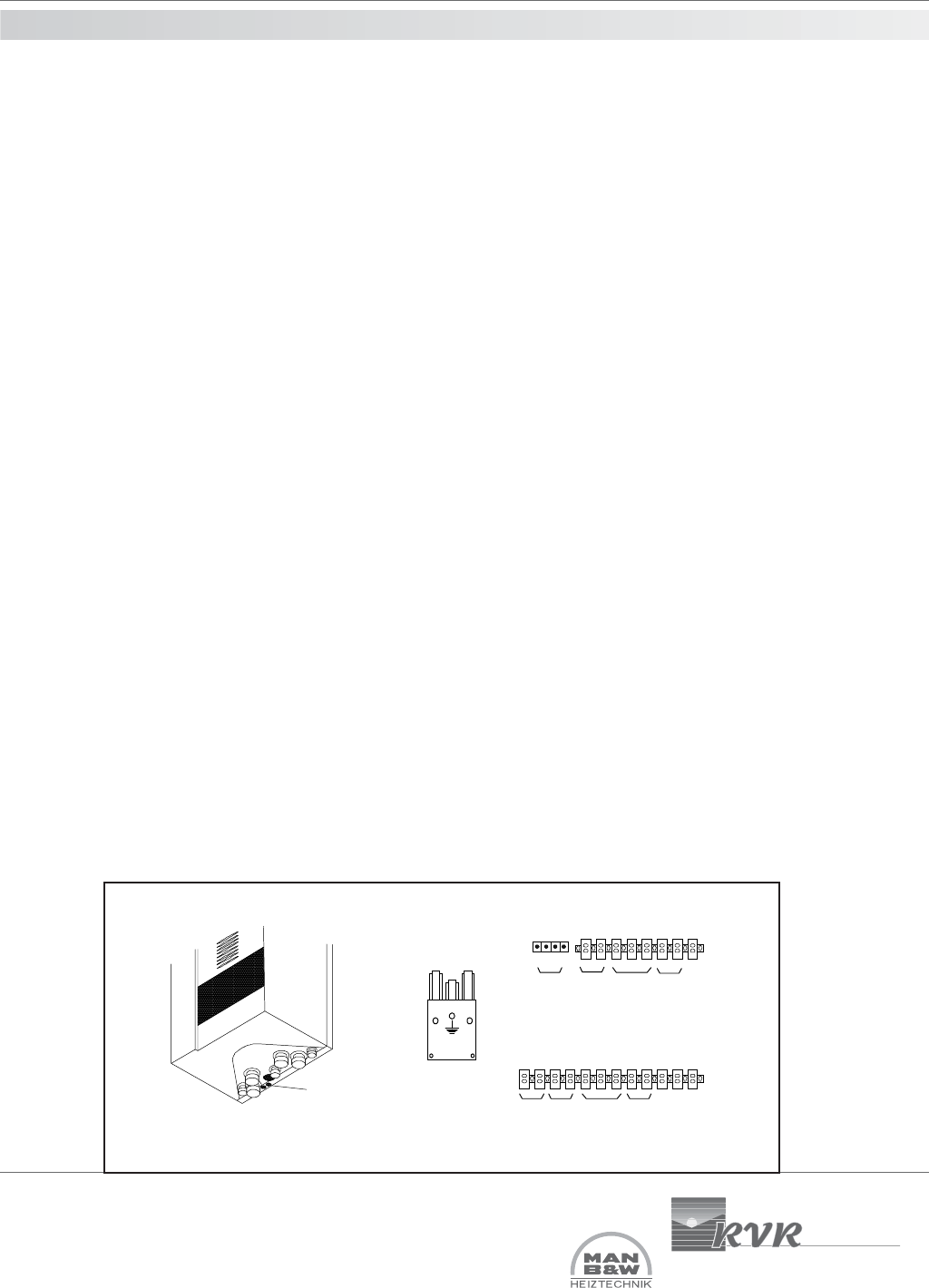

The electrical connections to the MICROMAT EC boiler are made via a Weiland Plug and socket (incoming live,

neutral and earth) and two terminal blocks which are located within the boiler case and below the control panel. The

lower terminal block is 24V d.c. and the upper terminal block is 220V a.c.

Connections must only be made using appropriate diameter multi strand flex cables and cable entry must only be

via the rubber glanded cable entry points located at the bottom rear r/h side of the appliance. If the boiler is to be

room sealed flued then care must be taken to ensure the cable entries are reasonably air tight.

For electrical connection plug/socket & terminal function and location see fig below.

17.0 electrical

connection

Cable

glands

1 2 3 4 R1 R2 R3 5 6

L1 N L1 N L2 L1 N

Front Terminal Block

DHW

Sensor

Outside Air

Sensor

RE2132

Not Used

External gas

valve or external

pump

Earth

MR03 and/

or Room

thermostat

2way 3port

mixing valve

or storage

water pump

Back Terminal Block

Wieland plug no. 1 -

Incoming Power

NL1

PE