Technical data

Table Of Contents

- User Instructions for the Micromat boiler

- Product Description

- Technical Data

- Delivery Consignment / Unpacking the boiler

- Boiler location

- Installation Clearances

- Wall Mounting

- Gas Connection

- Gas Conversion

- System Flow & Return connections

- Condensate Connection

- Flue / Combustion Air connection

- Flue Systems

- Calculating Flue Resistance

- Ventilation requirements single appliances

- Hydraulic System Design

- System type 1

- System type 2

- System type 3

- System type 4

- System type 5

- System type 6

- System type 7

- System type 8

- Water Treatment

- Soldering Flux

- Electrical Connection

- System Type 1

- System Type 2

- System Type 3

- System Type 4

- System Type 5

- System Type 6

- System Type 7

- System Type 8

- Commissioning The Micromat EC

- Installation Codes

- First Firing

- Pop Up Menu

- Setting DHW Temperature

- Servicing

- Screen Display Diagnosis of Faults

Energy Technology

Ltd.

27

16.0 hydraulic system

design

OS = Outside air temperature sensor, used where direct-on-boiler weather

compensated flow temperatures are required.

C = Room temperature controls e.g. RE2132 modulating room unit from RVR Ltd.,

or, separated time clock & room thermostat.

PR01 = Pump regulation module from RVR Ltd. Allows heating pump to be driven

from boiler, providing for auto operation, frost protector running & summer standstill

exercising.

Must be used where RE2132 modulating room unit is installed. Max pump motor

load 2A.

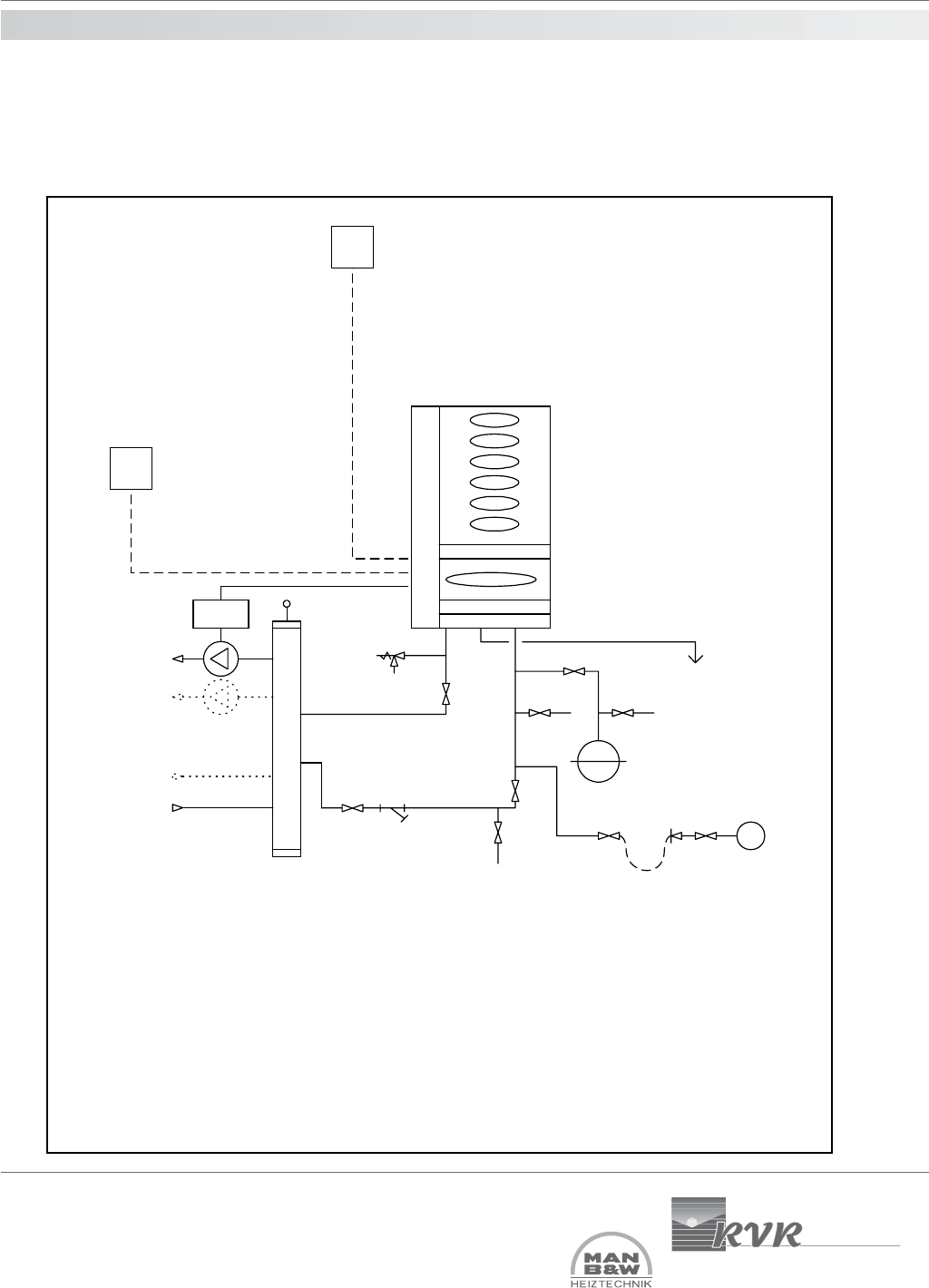

System type 3

Typical Single MICROMAT EC boiler installation serving heating only and using a low velocity mixing header

where system index resistance exceeds 1 metre. Flow temperature may be fixed/constant or weather variable.

Condensate

Micromat EC

boiler

LSV

IV

DOCDOC

Expansion Vessel

Safety Valve

CWM

IV

IV

Strainer

Flow to

system circuits

Return from

system circuits

DOC

AAV

Low velocity mixing header

Max. velocity 0.5m/s

OS

C

PRO 1