Technical data

Table Of Contents

- User Instructions for the Micromat boiler

- Product Description

- Technical Data

- Delivery Consignment / Unpacking the boiler

- Boiler location

- Installation Clearances

- Wall Mounting

- Gas Connection

- Gas Conversion

- System Flow & Return connections

- Condensate Connection

- Flue / Combustion Air connection

- Flue Systems

- Calculating Flue Resistance

- Ventilation requirements single appliances

- Hydraulic System Design

- System type 1

- System type 2

- System type 3

- System type 4

- System type 5

- System type 6

- System type 7

- System type 8

- Water Treatment

- Soldering Flux

- Electrical Connection

- System Type 1

- System Type 2

- System Type 3

- System Type 4

- System Type 5

- System Type 6

- System Type 7

- System Type 8

- Commissioning The Micromat EC

- Installation Codes

- First Firing

- Pop Up Menu

- Setting DHW Temperature

- Servicing

- Screen Display Diagnosis of Faults

Energy Technology

Ltd.

25

16.0 hydraulic system

design

System type 1

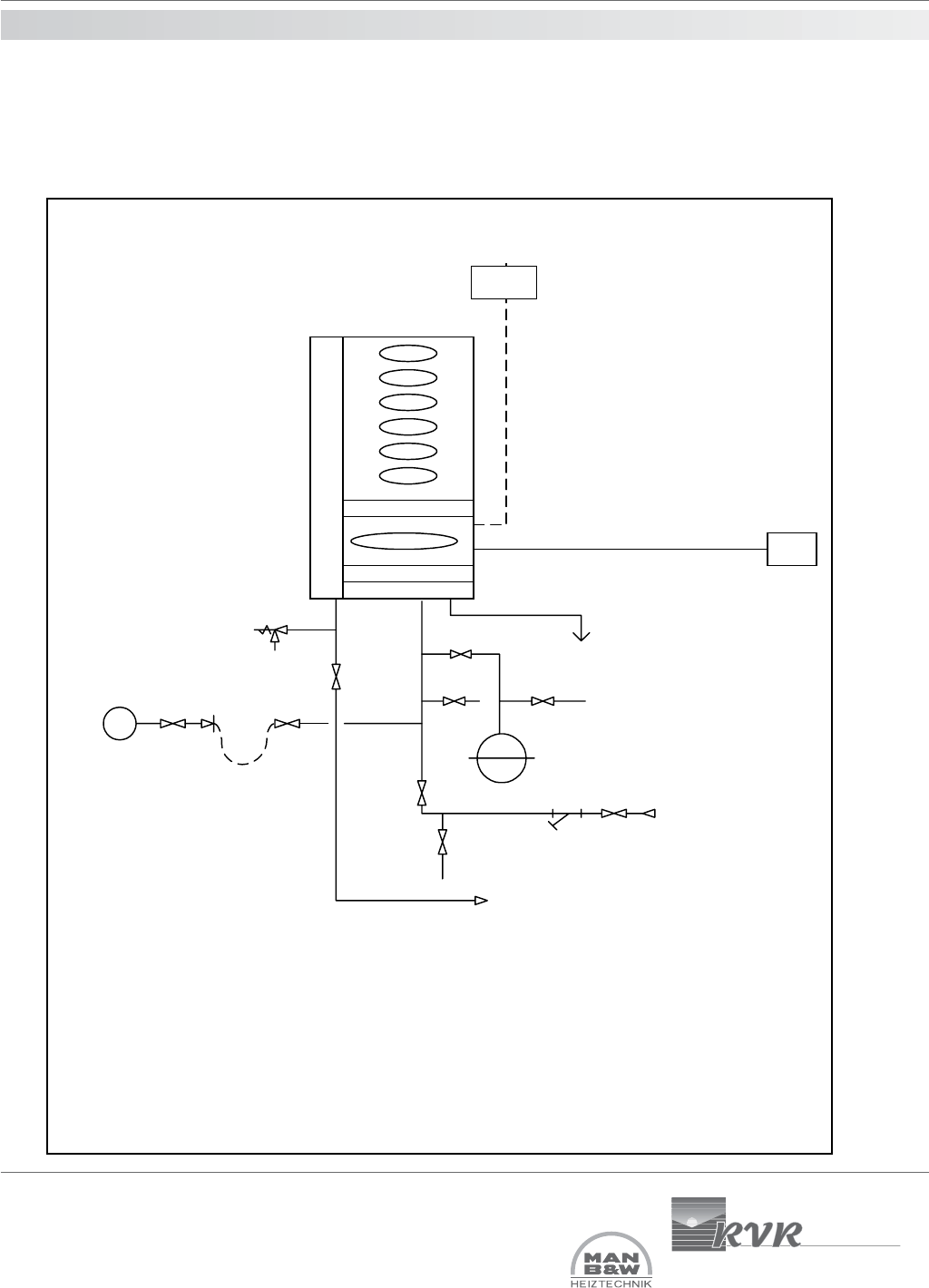

Typical Typical Single MICROMAT EC boiler installation serving heating only where the boiler’s own in-built circulating

pump is used to circulate the water around the system (used only where system index resistance <1 metre). Flow

temperature may be fixed/constant or weather variable.

Condensate

Micromat EC

boiler

IV

Safety Valve

Flow to

system

OS

C

LSV

DOC DOC

CWM

IV

IV

Strainer

Return from

system

DOC

Expansion Vessel

OS = Outside air temperature sensor, used where

direct-on-boiler weather compensated flow

temperatures are required.

C = Room temperature controls e.g. RE2132

modulating room unit from RVR Ltd., or,

separate time clock & room thermostat.