Technical data

Table Of Contents

- User Instructions for the Micromat boiler

- Product Description

- Technical Data

- Delivery Consignment / Unpacking the boiler

- Boiler location

- Installation Clearances

- Wall Mounting

- Gas Connection

- Gas Conversion

- System Flow & Return connections

- Condensate Connection

- Flue / Combustion Air connection

- Flue Systems

- Calculating Flue Resistance

- Ventilation requirements single appliances

- Hydraulic System Design

- System type 1

- System type 2

- System type 3

- System type 4

- System type 5

- System type 6

- System type 7

- System type 8

- Water Treatment

- Soldering Flux

- Electrical Connection

- System Type 1

- System Type 2

- System Type 3

- System Type 4

- System Type 5

- System Type 6

- System Type 7

- System Type 8

- Commissioning The Micromat EC

- Installation Codes

- First Firing

- Pop Up Menu

- Setting DHW Temperature

- Servicing

- Screen Display Diagnosis of Faults

20

14.0 calculating flue resistance-

flue pressure loss

example I

A MICROMAT EC 62 boiler is installed with a concentric

flue system which takes an all horizontal route to a wall

terminal. Length of flue = 3m including one 90° bend.

Resistance =

3 x 1m length 70/125 concentric tube @ 16.6 Pa = 49.8

1 x 90° 70/125 concentric bend @ 16.6 Pa =16.6

I x 70/125 concentric wall terminal @ 21.4 Pa = 21.4

Total Resistance = 87.6Pa

conclusion: Total resistance is less than 100 Pa. therefore,

no alternative design required and no effect on boiler output,

or positioning required

example 2

A MICROMAT EC 45 boiler is installed with a concentric

flue system which takes a part horizontal, part vertical route

to a roof terminal with rain cap.

Length of horizontal section = 1m, vertical section = 6m,

system includes 1 x 90

o

bend.

Resistance =

7 x 1m lengths 70/125 concentric tube @ 10.7 Pa = 74.9

1 x 90° 70/125 concentric bend @ 10.7 Pa= 10.7

1 x 70/125 roof terminal @ 21.9 Pa = 21.9

Total Resistance = 107.5 Pa

Take into account that 6m of vertical (assume uninsulated,

as air for combustion direct from outside air surrounds the

flue gas tube) flue creates 10 Pa of up-draught,

then final resistance = 107.5 - 10 = 97.5 Pa.

conclusion: Final operating resistance is less than 100 Pa,

therefore, no alternative design required and no effect on

boiler output.

example 3

A MICROMAT 1-75 boiler is installed (non room sealed) with

a proposed flue using DN 70 PPS single skin flue compo-

nents which takes a part horizontal, part vertical route to a

vertical open termination with bird mesh.

Length of horizontal section = 4m, length of vertical

(uninsulated) section = 11m with 4 x 90

o

bends,

and 2 x 45

o

bends.

Resistance =

15 x 1m lengths DN 70 PPS tube @ 21.4 Pa = 321

4 x 90

o

DN 70 PPS bends @ 21.4 Pa = 85.6

2 x 45

o

DN 70 bends @ 10.7 Pa = 21.4

1 x DN 80 open termination @ 15.6 Pa = 15.6

Total Resistance: 443.6 Pa

Take into account that 11m of vertical uninsulated flue

creates 18 Pa of up-draught, then final resistance would be

443.6-18 = 425.6 Pa.

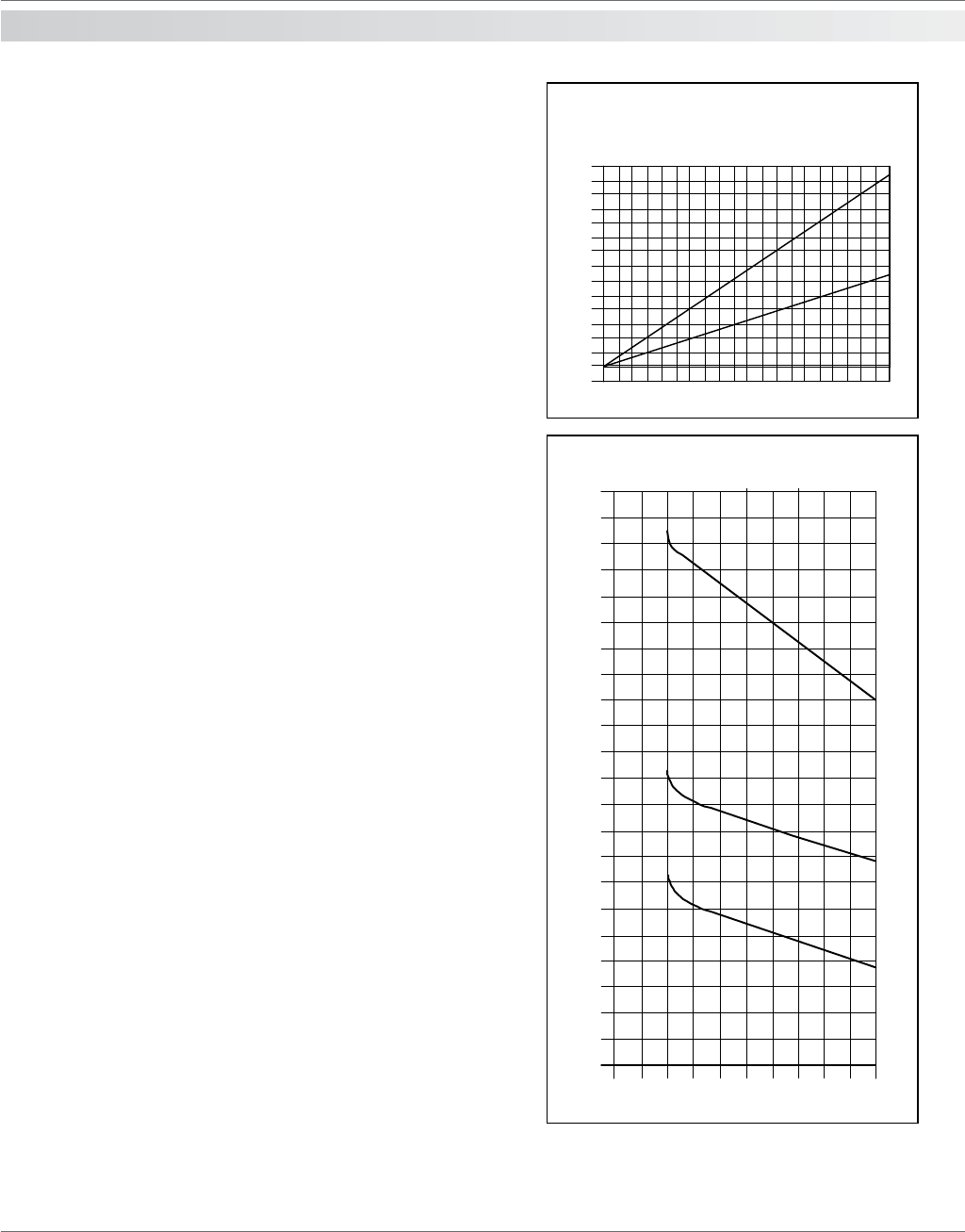

Reference to the graph of resistance effect on boiler output

shows the output would be reduced to approximately 59kW.

If this is unacceptable, then the flue resistance must be re-

calculated using a larger size flue tube as shown below or

consideration given to moving the boiler position.

Re-calculating proposed flue installation using DN 100.

15 x 1m lengths DN 100 PPS tube @ 3.0 Pa = 45

4 x 90

o

DN 100 bends @ 3.0 Pa = 12

2 x 45

o

DN 100 bends @ 1.5 Pa = 3.0

1 x DN 100 open termination @ 4.0 Pa = 4.0

Total Resistance: 64 Pa

Take into account thermal up-draught created (as before)

18 Pa. Therefore operating resistance = 64 – 18 = 46 Pa,

with no effect on boiler output.

140

130

120

110

100

90

80

70

60

50

40

30

20

10

0

0 2 4 6 8 101214161820 2224262830323436 3840

Vertical Flue Lengths - metres

Draught - Pa

29

31

33

35

37

39

41

45

47

49

51

53

55

57

59

61

63

65

67

69

71

73

43

0 50 100 150 200 250 300 350 400 450 500

Flue System resistance - Pa

MICROMAT EC76

MICROMAT EC 62

MICROMAT EC 45

thermal updraught when

flue gas temp 80°C and outside temp -5°C

A = Insulated or within the building

B = Uninsulated and exterior to the

building

effect of flue system resistance

on boiler output

Boiler output kW at: flow 80°C Return 60°C

A

B