Technical data

Table Of Contents

- User Instructions for the Micromat boiler

- Product Description

- Technical Data

- Delivery Consignment / Unpacking the boiler

- Boiler location

- Installation Clearances

- Wall Mounting

- Gas Connection

- Gas Conversion

- System Flow & Return connections

- Condensate Connection

- Flue / Combustion Air connection

- Flue Systems

- Calculating Flue Resistance

- Ventilation requirements single appliances

- Hydraulic System Design

- System type 1

- System type 2

- System type 3

- System type 4

- System type 5

- System type 6

- System type 7

- System type 8

- Water Treatment

- Soldering Flux

- Electrical Connection

- System Type 1

- System Type 2

- System Type 3

- System Type 4

- System Type 5

- System Type 6

- System Type 7

- System Type 8

- Commissioning The Micromat EC

- Installation Codes

- First Firing

- Pop Up Menu

- Setting DHW Temperature

- Servicing

- Screen Display Diagnosis of Faults

12

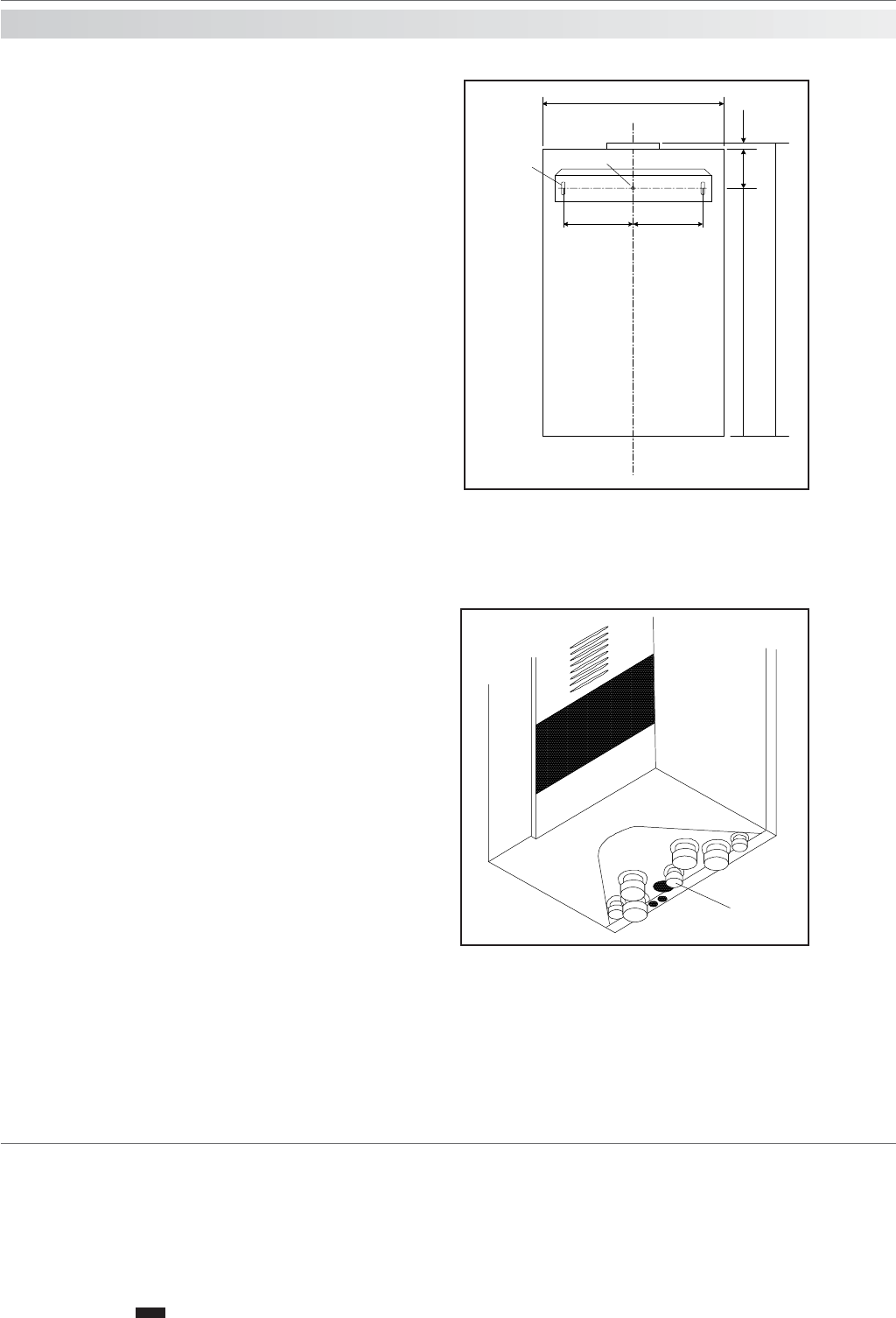

The MICROMAT EC boiler mounts to the wall via a wall

mounting bracket which interlocks to a rail mounted on the

rear of the boiler. The wall mounting bracket should be firmly

fixed to the wall using suitable fixings with a countersunk

head. The wall mounting bracket positioning detail is shown

in fig 1. The boiler must be carefully offered up to the wall

so that the rail on the rear of the boiler is just above the

wall mounting bracket and then the boiler should be lowered

to engage the bracket and rail. Lifting is advised with 2

persons. Do NOT lift the boiler by the internal parts of the

appliance.

important

When viewed from the side, the north/south axis of the

boiler must be vertical. The appliance must not be inclined

out from the top, if necessary block or shim behind the

bottom rear of the boiler to achieve a vertical installation.

8.0 wall

mounting

The gas connection is located at the base of the appliance

rear r/h side, see fig 2.

The pipe size used to supply the appliance must not be

smaller than the gas connection size on the appliance.

The connection to the appliance must include a suitable

method of disconnection and a gas control cock must be

installed adjacent to the appliance for isolation purposes.

The gas pipe used to supply the appliance must not allow a

pressure drop of greater than 1mbar from the meter to the

appliance.

The nominal inlet working gas pressure measured at the

appliance should be 20.0 mbar for Nat Gas

(G20) or 37 mbar for LPG (G31).

9.0 gas

connection

∅

12

2x35x12

458

945

785 115 45

165 165

Gas

Connection