Owner's manual

Table Of Contents

- Content

- Overview

- Operation with the keyboard

- Error messages, troubleshooting

- Diagnosis

- General

- Summary

- Prepare instruments for diagnostic tests

- Diagnosis of cylinder code

- Diagnosis of key board

- Diagnosis of display

- Diagnosis analog output

- Diagnosis of digital timer

- Diagnosis of analog timer

- Diagnosis of external inputs, outputs

- RAM-test

- Diagnosis of spindle zero and cock changeover

- Diagnosis of spindle drive

- RAM-initialisation

- Releasing a locked spindle

- Operation via RS232 Interface

- Appendix

- Index

3.4 Releasing a locked spindle

765 Dosimat

31

3.4 Releasing a locked spindle

with inserted Exchange Unit

The burette drive may very occasionally jam at the top or bottom end of the cylinder. If

jamming occurs at the top or when the drive is out of function, the Exchange Unit can no

longer removed. In this case, it is necessary to proceed as follows:

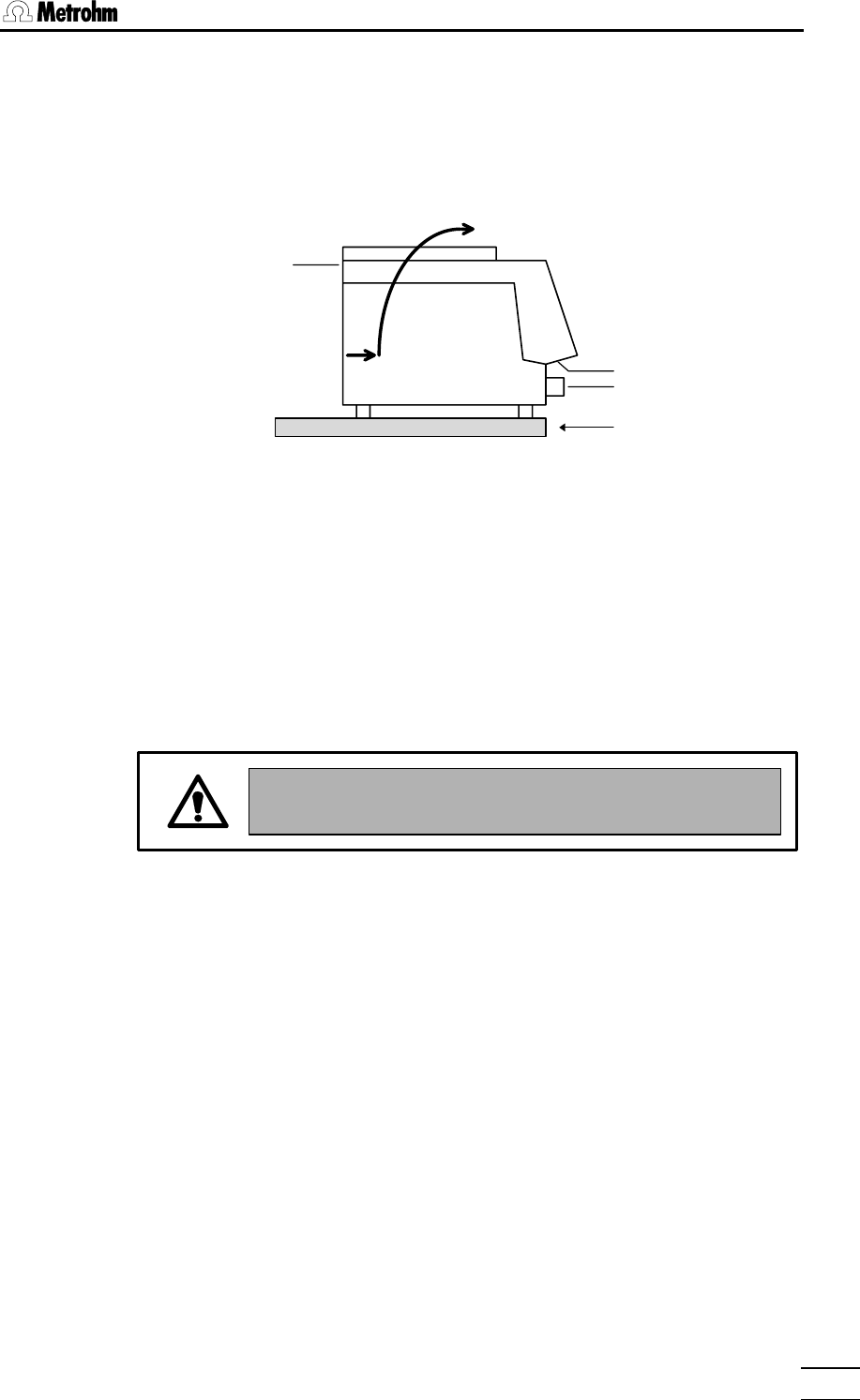

2 screws (M3 fillister head)

knob

edge of bench

2 screws (M4 countersunk)

Fig. 4

1.

Disconnect instrument from power supply!

2.

Remove control knob.

3.

Place instrument over edge of bench to allow the M3 screws to be removed.

4.

Remove M4 screws.

5.

Lift off top part of instrument together with Exchange Unit in the manner shown by

the arrow.

The electronic circuits are now accessible!

On no account touch these!

6.

Remove spindle from mechanical stop by turning the large gear wheel. (In case

that the motor is inoperative, position spindle by hand to zero position.)