Owner's manual

Table Of Contents

- INDEX

- Bench Test 3

- Connections 3

- Keypad System 4

- Menu - Flow Chart 4

- Run 6

- Totalizer (Flow Mode) 6

- Password 6

- Units / Mode 7

- Flume Selection 9

- Calibration - for Level 10

- Calibration - for Open Channel Flow 11

- 4-20mA Current Loop Offset 12

- Rejection Time 12

- Relay Parameters 13

- Special Functions 15

- Sensor Location - Tank Level 17

- Sensor Mounting/Location - Open Channel 20

- Enclosure Installation 23

- Error/Warning Messages 24

- Field Troubleshooting 25

- Installation Considerations In Noisy Environments 27

- Customer Service 29

- Instrument Return Procedure 29

- Appendix A - Options 30

- Data Logger 32

- RS232C Serial Output 38

- Appendix B - Applications Background 41

- Conversion Guide 42

- Specifications 43

- Calibration Worksheet - Level Mode 46

- Calibration Worksheet - Flow Mode 47

- Units/Mode 1

- Warranty 1

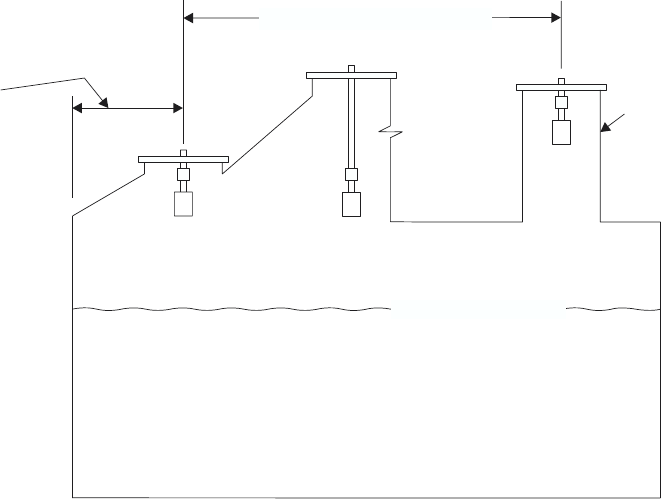

SENSOR MOUNTING LOCATION

- Tank Level/Inventory Applications

SENSOR MOUNTING

Each sensor is equipped with a 3/4 inch “isolation coupling” which MUST be used in your installation.

A threaded nipple or length of conduit may be used to position the sensor at the desired height.

The sensor should be hand-tightened (like a light bulb) by turning the sensor stem only. DO NOT use a

wrench and do not over tighten. DO NOT clamp the sensor below the isolation coupling.

Page 18

AquaMetrix

Ultrason

SENSOR FACE MUST

BE HORIZONTAL ±1°

1 FT (30 cm) HORIZONTAL

FROM SIDEWALL FOR

EVERY 10' (3 m) VERTICAL

NOTE: 2 FT (60 cm) FOR

EVERY 10' (3 m) DEPTH ON

A

PPLICATIONS WITH ROUGH

SIDEWALLS, LADDERS,

REINFORCING RINGS ETC.

MAX. LIQUID LEVEL

PREFERRED SENSOR

LOCATION

6" SCHEDULE 4

0

STAND PIPE IF

EXTENSION

REQUIRED