Operation Manual

11

ENGLISH

A

Caution!

The condensate contains oil

and must be disposed of at a proper

collecting point.

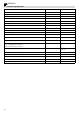

• Clean air filter element (25) of filter/

regulator unit.

• Drain the condensate from the filter/

regulator unit into a container

(26).

A

Caution!

The condensate contains oil

and must be disposed of at a proper

collecting point.

Every 250 operating hours

• Replace air intake filter element of

compressor pump.

• Replace air filter element of filter/

regulator unit.

Every 500 operating hours

• Change the crankcase oil.

Every 1000 operating hours

• Have unit serviced by an authorized

service station. This will extent the

compressor's service life considera

-

bly.

5.2 Device storage

1. Switch unit OFF and unplug.

2. Release pressure from tank and all

connected air tools.

3. Store device in such way that it can-

not be started by unauthorized per-

sons.

A

Caution!

Do not store device unpro-

tected outdoors or in damp environ-

ment. Do not lay device on its side for

transportation or storing.

A

Danger!

Prior to all servicing:

− Switch Off.

− Unplug.

− Wait until the device has come to

a complete stop.

− Ensure the device and all air tools

and accessories connected to it

are relieved from pressure.

− Let the device and all air tools

and accessories used cool off.

After all servicing:

− Check to see that all safety

devices are operational.

− Make sure that no tools or other

parts remain on or in the device.

Compressor does not run:

• No mains voltage.

− Check cables, plug, outlet and

mains fuse.

• Mains voltage too low.

− Use only extension cables with

sufficient lead cross section (see

"Technical Specifications"). Avoid

using extension cable with cold

device.

• Compressor was stopped by

unplugging.

− Switch compressor OFF at the

On/Off switch, then ON again.

• Motor has overheated, caused by

insufficient cooling (cooling fins

covered).

− Remove cause for overheating

and allow to cool down for

approx. 10 minutes, then start

again.

Compressor runs but does not build

up sufficient pressure.

• Condensate drain of pressure ves-

sel leaky.

− Check gasket of drain screw(s);

replace if necessary.

− Tighten drain screw(s) fingertight.

• Drain cock on cup of filter/regulator

unit open.

− Tighten drain screw fingertight.

• Check valve leaky.

− Have check valve serviced by

qualified service centre.

Air tool is not supplied with sufficient

pressure.

• Pressure regulator not opened wide

enough.

− Open pressure regulator more.

• Hose connection between compres-

sor and air tool leaky.

− Check air hoses, replace defec-

tive parts if necessary.

A

Danger!

Repairs to power tools must be

carried out by qualified electricians

only!

Electric tools in need of repair can be

send to the service centre in your coun

-

try. See spare parts list for address.

Please attach a description of the fault to

the power tool.

The device's packaging can be 100 %

recycled.

Worn out devices and accessories con-

tain considerable amounts of valuable

raw and plastic materials, which can be

recycled.

These instructions are printed on chlo-

rine-free bleached paper.

24

25

26

6. Trouble Shooting

7. Repairs

8. Environmental Protection