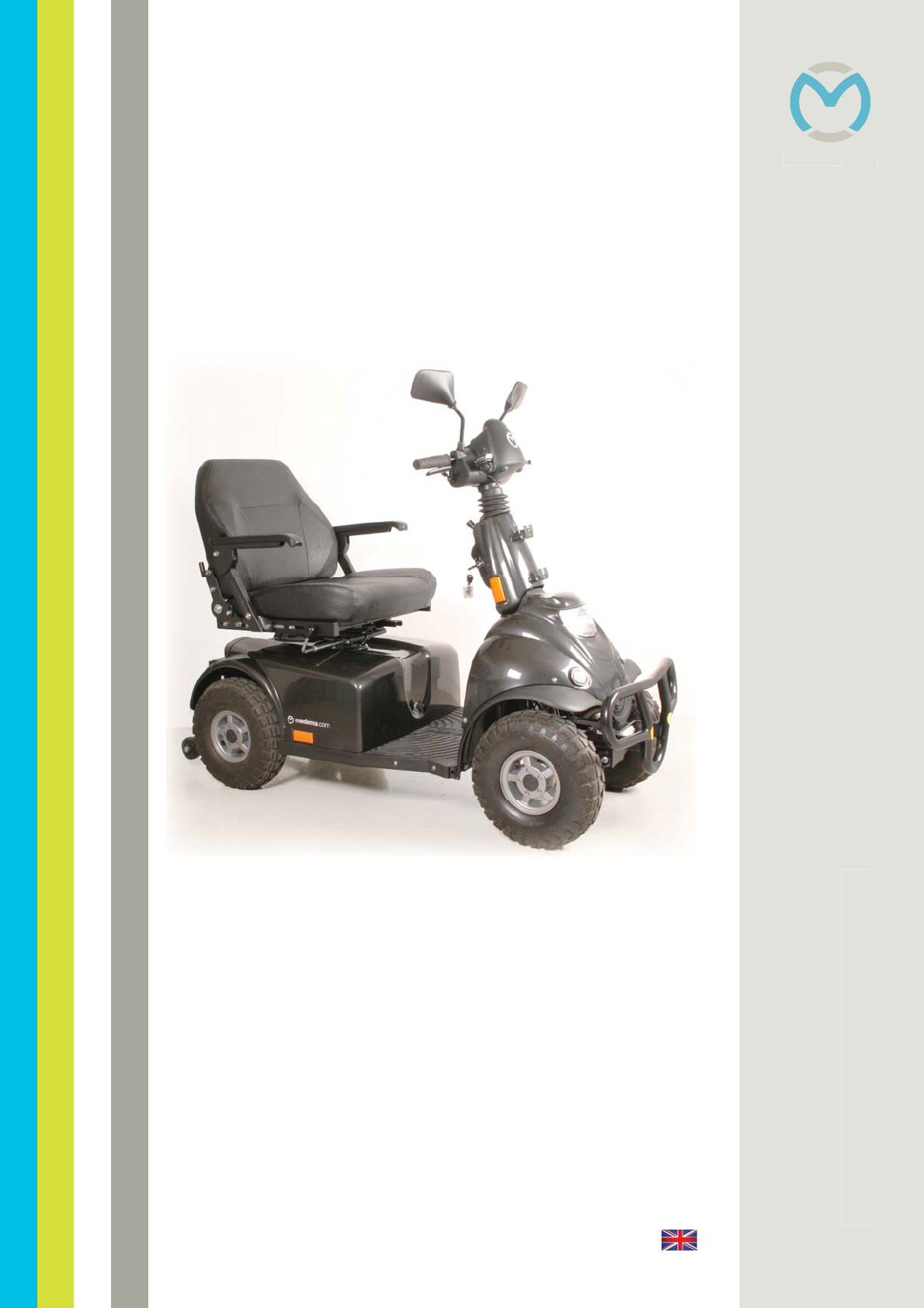

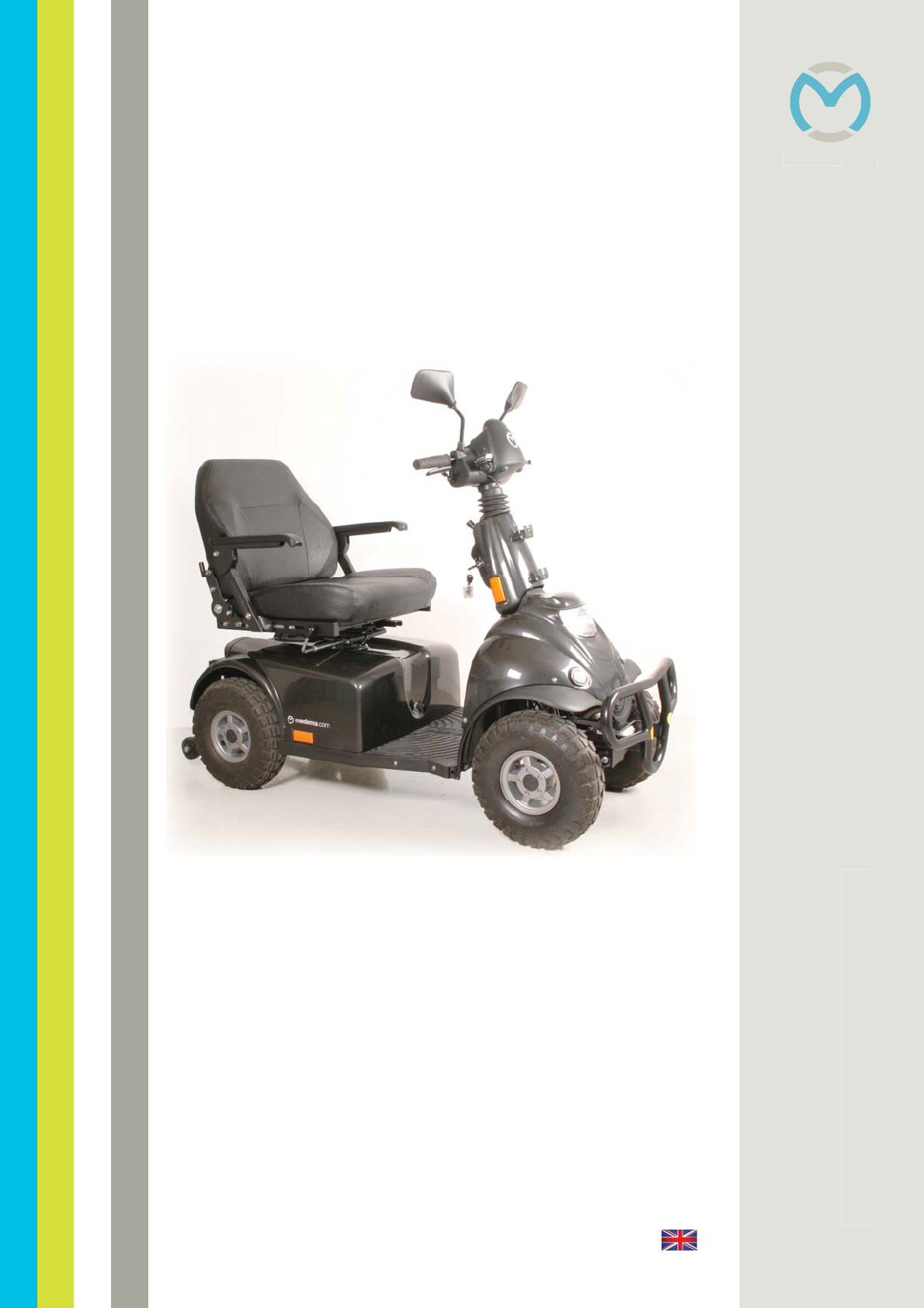

User Manual Mini Crosser M-MaxX medemagroup P9-0135-B ver. 1.0.

Medema Production A/S Serial number: ___-______________-______-_______ Delivery date: ________________ Year 20______ This vehicle was supplied by: User guide P9-0135-B Date: 2 of 52 / Version 1.0.

Medema Production A/S Contents Symbols.................................................................................. 4 Warning! ................................................................................. 4 Contagion!.............................................................................. 4 Introduction............................................................................ 5 Declaration of conformity ..................................................... 6 Control panel .................

Medema Production A/S Symbols Used in the manual to indicate sections describing situations where extra care is required owing to the risk of personal injury. Used to indicate sections on electromagnetic compatibility (EMC). Warning! The Mini Crosser M-MaxX is a powerful vehicle, equipped with 2 motors. One on each rear wheel. Therefore, careful training on the use of the vehicle is required. For safety reasons the vehicle must not be lent to persons who are not completely familiar with it.

Medema Production A/S Introduction Congratulations on your new Mini Crosser M-MaxX electric mobility scooter. You have now taken possession of an electric mobility scooter developed for outdoor driving by active users. It is what is called a Class C vehicle in accordance with the European classification of electric scooters. For optimum enjoyment of this vehicle - and to avoid breakdowns and accidents - we recommend that you read this User Manual carefully.

Medema Production A/S Declaration of conformity Medema Production A/S hereby declares that: Machine: Mini Crosser Use: (Prescribed use in User Manual) Model No: M-MaxX Complies with the Medical Device Directive 93/42/EEC The product is made in accordance with the harmonized standard EN 12184 - Electrically powered wheelchairs, scooters and their chargers. The product is risk analysed in accordance with the harmonized standard DS/EN ISO 14971:2007-04-10 2.

Medema Production A/S Control panel Avoid subjecting the control panel to jarring and knocks. Take care when driving and avoid hitting obstacles. The manufacturer accepts no liability in respect of the unauthorised opening, adjustment or modification of the control panel.

Medema Production A/S Designation Description Key switch To start the vehicle: Turn the key to driving position (1) When the Mini Crosser is turned on, the control system performs a safety check of the electrical system. The check lasts half a second. If the accelerator is operated during this time, the Mini Crosser will not be able to move until you have turned the key to 0 and back to 1. Speed selector The tortoise in minimum position indicates the lowest speed range.

Medema Production A/S Preparations / Adjustments prior to use Adjusting the height of the seat Lift the seat off and remove the rear cover. Press the release button out and adjust the seat tube to the desired position. See the picture on the next page. Check that the seat height is correct and press the release button in again. Move the seat tube up/down until the release clicks into a hole. Make sure you keep your back straight when lifting the seat, which is very heavy. (See below.

Medema Production A/S Seat tube Release Seat tube in top position. There are five holes for adjusting the seat tube. The release must be in a hole for the seat to be stable. User guide P9-0135-B 10 of 52 Version 1.0.

Medema Production A/S Seat rotation Pull the release lever back. The seat can be rotated 90° to either side. When the lever is released, it engages with the seat and holds it in place at 45° intervals. Other seats that can be supplied for the Mini Crosser work on similar principles. The release lever is normally mounted on the right, but can be put on the left if so wished. Release lever for seat rotation. Release lever for seat forward/back. User guide P9-0135-B 11 of 52 Version 1.0.

Medema Production A/S Steering column Can be adjusted forward/back with the release lever. Pull down on the lever and pull the handlebars closer for a good driving position. Use the lever again and push the steering column forward to make it easier to get out. The height of the steering column can be adjusted approx. 11 cm up/down. First remove the rubber plug covering the Allen screw. Adjust the height using a 4 mm Allen key. Adjusting the angle of the handlebars.

Medema Production A/S Serial number All vehicles have a serial number plate showing the year of production and serial number. The same serial number can also be found on the front of the User Manual. Please quote this number when making inquiries about servicing, spare parts, etc. Maximum user weight Model description Vehicle’s unladen weight inc. batteries and seat Serial number Year of production Max. speed Position of serial number plate on vehicle. User guide P9-0135-B 13 of 52 Version 1.0.

Medema Production A/S Driving the Mini Crosser M-MaxX Getting in and out It is important to learn a safe technique for getting in and out of the Mini Crosser. In general the following method should be followed: • • • • • Make sure that the Mini Crosser M-MaxX is off (switch turned to 0) when getting in and out, otherwise the Mini Crosser could start if the accelerator was touched inadvertently. Make sure that the brake is on. (Lever for disengaging motor in top position.

Medema Production A/S Braking systems There are three braking systems on the Mini Crosser: • Motor brake - adjusts vehicle speed also when going downhill. • Magnetic brake - the magnetic brake is automatic and engages when the Mini Crosser stops. In an emergency, the Mini Crosser can be stopped instantaneously by turning the key switch. Please note that this will cause very sharp braking. The rear wheels will lock. Must NOT be used in the normal course of driving.

Medema Production A/S Never drive when under the influence. This applies not only to alcohol, but also to drugs and medicines. Reduce speed immediately if you feel you are losing control. Always use the indicators when changing direction. Check that lights and indicators are working before driving off. Use your lights when driving after lighting-up time. As far as possible, grip the handlebars firmly with both hands.

Medema Production A/S New users are urged to practise the following in an area where there is no other traffic: • Set the Mini Crosser to low speed. Drive forwards and backwards. Gradually turn the speed selector up and feel the change in the speed of the Mini Crosser. • Practise starting and braking. Get used to the Mini Crosser’s response time. • Practise driving in a narrow space, similar to inside a shop or through a door. • Practise turning, and get a sense of how much space is required.

Medema Production A/S Traffic regulations The traffic legislation for scooters varies from country to country. Before starting to use the vehicle outdoors, it is the user’s responsibility to familiarise him/herself with the relevant legislation. The following rules apply in Denmark: Mobility vehicles such as the Mini Crosser with a maximum speed of up to 11.5 km/h count as cycles in traffic legislation and the traffic regulations for cycles must be followed at speeds in excess of 6 km/h.

Medema Production A/S Electromagnetic compatibility If the Mini Crosser starts making involuntary movements or if the brakes are released, turn the Mini Crosser off as soon as it is safe to do so. In certain circumstances a Mini Crosser can set off shop alarms. The Mini Crosser satisfies the requirements for the use of scooters in an environment with electromagnetic noise. There may, however, be rare situations in which electromagnetic noise can affect the Mini Crosser.

Medema Production A/S Specific driving situations Up kerbs • • • • Stop at right angles to the kerbstone about 5-10 cm away from it. Keep an eye on other road users. Lean forwards. Accelerate moderately so that your vehicle can overcome the obstacle. Do not stop halfway, but reduce speed once the vehicle is up. If the kerb is too high, do not try again, but find an alternative route. Down kerbs • • • User guide P9-0135-B Lean back.

Medema Production A/S Up a ramp/hill • • • • There is a risk of tipping over backwards if the seat is pushed back when you start driving up a slope, e.g. a ramp. Pull the seat forward! Check that any ramp is stable. Lean forwards. Accelerate moderately so that your vehicle can overcome the obstacle. Do not stop halfway. Reduce speed once the vehicle is up. If you need to start on a hill, accelerate slowly so as not to tip over backwards.

Medema Production A/S Across a slope • • • Lean into the slope. Avoid sudden and sharp movements. This is particularly relevant when reversing. Always drive at low speed. Long hills/difficult ground The Mini Crosser is at risk of overheating on very long and steep hills or on very soft ground, possibly also combined with high user weight. To protect your Mini Crosser’s motor from overheating, there is a built-in Thermo switch that will make the Mini Crosser stop if the motors become too hot.

Medema Production A/S Anti-tilt wheels / stabilisers The Mini Crosser is a very stable vehicle. HOWEVER, in the case of incorrect weight distribution or careless driving there is a risk of tipping over. We therefore recommend fitting anti-tilt wheels in such circumstances. (See picture below) (Anti-tilt wheels / stabilisers are optional extras.) Anti-tilt wheels User guide P9-0135-B 23 of 52 Version 1.0.

Medema Production A/S General care and maintenance A Mini Crosser M-MaxX does not require much maintenance. It should be kept in a generally good condition, however. The following should be checked regularly: • • • • Tyre pressure (if pneumatic tyres are fitted) Tyre wear Keep the control panel, the charging socket and the electronics box under the seat dry. Battery charging Never wash the Mini Crosser with a high-pressure cleaner or direct water jet! This could damage the Mini Crosser’s electronics.

Medema Production A/S Annual The Mini Crosser M-MaxX is designed for safe travel for at least 10 years, up to a max. of 5,000 hours, provided it is serviced and safety-checked every year, corresponding to 500 hours of operation. The service must be carried out by an authorised workshop.

Medema Production A/S Batteries The Mini Crosser uses sealed, maintenance-free GEL batteries (Exide 12 V/56 Ah or AGM 12 V/71 Ah). They do not generate gas and do not have to be topped up with water. Charging Please NOTE that the Mini Crosser can be equipped with several types of charger (ask your dealer for information on the various types). IMPORTANT! Only ever use a charger designed for charging dry maintenance-free batteries. The max. charging current is 12 A.

Medema Production A/S Avoid draining the batteries completely. We recommend charging the batteries in a heated room. If it is not possible to do this every day, it is a good idea to charge the Mini Crosser in a heated room (approx. 20°C) once a week. New batteries do not reach full capacity until they have been charged and discharged about 20 times. It is IMPORTANT to fit the batteries correctly. The battery terminals and snap locks are marked +/-. They must be fitted as shown in the sketch below.

Medema Production A/S Battery disposal Used batteries must be disposed of through your supplier or at a recycling centre. Take care when handling leaky batteries, as the gel contains corrosive acid. INFO! New batteries can be purchased from Medema Danmark A/S. Storage The scooter should be stored and charged under cover, preferably at temperatures above 0°C. Note! The charger must be kept dry, but should not be covered when in use.

Medema Production A/S Changing the wheels If you get a puncture in one of the pneumatic tyres or if a tyre is so badly worn that it needs to be replaced, follow the instructions below. Tyres and inner tubes can be purchased from the authorised dealer who supplied the Mini Crosser. The Mini Crosser must be TURNED OFF before you start. Changing the wheels on the 4W model 5 mm Allen key • • • Undo the five bolts. Take the wheel off.

Medema Production A/S Remove the flange with the 5 screws (5mm Allen). Replace or patch the tube. Ensure that there are no foreign objects in the tyre before the tube is replaced. Pump in a little air but do not fill it up yet. Replace the flange. Pump up the wheel to the correct pressure. (See technical data) Fit the wheel onto the Mini Crosser again. REMEMBER! The spring washers between the screws and the wheel rim. User guide P9-0135-B 30 of 52 Version 1.0.

Medema Production A/S Fuses The Mini Crosser has the following protection systems: • Automatic overload protection, which limits the current to the motor. This protection is integral to the control system and cannot be adjusted. It prevents both the control system and the motor from being overloaded. In the event of overload the current to the motor is reduced - full speed and traction can be resumed after the motor has cooled down for 2-5 minutes. • The control fuse protects against mains faults.

Medema Production A/S Brakes There are three braking systems on the Mini Crosser M: • • Motor brake Magnetic brake • Motor brake: adjusts vehicle speed also when going downhill. • Magnetic brake: automatic and comes on when accelerator is released. It also acts as a parking brake when the Mini Crosser is at a standstill. In an emergency, the Mini Crosser can be stopped instantaneously by turning the key switch. Please note that this will cause very sharp braking.

Medema Production A/S Disengagement lever pushed up Electrical release • Hold the disengagement button pressed in to disengage (can be pushed or towed with max 5 km/h – see section about Towing). As soon as you let go of the disengagement button, the motor brake is working again (normal driving now possible). Disengagement button NOTE! The motor brake must never be disengaged on sloping terrain. Towing If you should be unfortunate enough to break down, the Mini Crosser can be towed or pushed.

Medema Production A/S Transporting by motor vehicle The Mini Crosser must always be restrained during transport in a motor vehicle or trailer. Avoid lifting by the seat, covers, handlebars and armrests If you just need to lift the scooter slightly, take hold of it between the rear lights and by the front bumper. Secure it in the vehicle with belts attached to the two eyes at the front and two at the back. All the eyes are marked in yellow. See the section entitled “Securing to vehicle floor with belts”.

Medema Production A/S Securing to vehicle floor with belts Dahl Engineering belt set for securing in motor vehicles. Item No. C2-0242 ALWAYS use four belts at the back and two at the front. The belts must always be attached to approved fittings in the vehicle and the four eyes welded to the scooter. The belts MUST be attached within the angles shown in the picture for optimum security. 45˚ User guide P9-0135-B 45˚ 35 of 52 Version 1.0.

Medema Production A/S Attachment point Attachment point Greater than the anchorage points on the scooter Centre line User guide P9-0135-B 36 of 52 Greater than the anchorage points on the scooter Version 1.0.

Medema Production A/S 1075 mm Dimensioned drawing, Mini Crosser M-MaxX 4W 650 mm 175 mm 135 mm 520 mm M2+: 290 mm 1030 mm 1500 mm User guide P9-0135-B 526 mm 680 mm 1620 mm 37 of 52 Version 1.0.

Medema Production A/S Introduction to seats - Ergo Standard Lever for seat rotation Pull the lever back to release the seat. The seat can then be turned 90° to either side with a stop every 45°. The lever is spring-loaded and the seat locks automatically when the lever is released. This lever is located on the right as standard, but can also be put on the left. Lever for seat forward/back Pull the lever out/up to release the seat on the slide rail. The seat can then be moved forward or back as required.

Medema Production A/S Adjusting the angle of the backrest The angle of the backrest can be adjusted by about 30°. This can be done by undoing the adjusting screw and changing the position of the spacer. Do the screw up again after making the adjustment. Optional extra: The seat can be fitted with a gas cylinder for adjusting the angle of the backrest. Armrest forward / back: The armrest can be moved forward / back on the C-rail. This can be done by undoing the screws indicated.

Medema Production A/S Introduction to seats - Mando Adjusting the angle of the backrest: The angle of the backrest can be adjusted by about 30° by raising this lever. Adjusting the angle of the armrest: The angle of the armrest can be adjusted by turning this screw. Adjusting the height of the armrest: The armrest can be raised/ lowered by undoing the two screws and moving the bracket one hole up or down. Headrest: The headrest can be raised and lowered steplessly.

Medema Production A/S Troubleshooting The following is a list of various problems that, in our experience, may occur. The list gives possible causes and remedies. Problem Possible causes Remedy The Mini Crosser will not go. The key has not been turned to start. The battery indicator is not lit. Turn the key and wait 5 sec. before activating the accelerator. Charge the batteries. The batteries are completely flat. The control fuse has blown. Change the fuse. The main fuses have blown.

Medema Production A/S Problem Possible causes Remedy The “ready” lamp on the charger lights up even when partly discharged batteries are connected. Contact supplier. The fuse in the charger has blown. The switch in the charging Contact suppliers - read plug is malfunctioning. the operating instructions for the charger. The charger lamp is showing an error. The charging plug has not been inserted or there is a mains fault. The battery voltage is too low for charging to start.

Medema Production A/S 2,2 HPD HPD fault 1. Wrong sequence of KSI, power activation and input data for throttle 2. Wrongly set potentiometer for throttle 2,3 PROC/WIRING FAULT HPD fault displayed for >5 sec. 1. Wrongly set throttle 2. Potentiometer for throttle defective 3. Throttle mechanism defective 2,4 SPD LIMIT POT FAULT Fault in speed limit potentiometer 1. Wiper cable for speed limit potentiometer defective 2.

Medema Production A/S Programming NOTE! For safety reasons, modifications may only be made by trained personnel, such as Mini Crosser service engineers and consultants or authorised service personnel at mobility centres, etc. Technical data M-MaxX General information: Transport height without seat (Steering column folded down) 70 cm Total length: Total length incl. anti-tilt wheel: Total width: 150 cm 162 cm 68 cm Total weight incl. batteries and HD 55 cm seat.

Medema Production A/S M-MaxX M-127-3-065 13x3.00-8” ext. Ø340 mm Wheel black - T and M-model 3,5 bar T-127-3-068 13x3.00-8” ext.

Medema Production A/S M-MaxX 110/115 Ah batteries Option Maximum driving distance with new batteries at +20° on flat, firm surface 41 km Optimum battery capacity is reached after approx. 20 charges / discharges. Battery type: Standard: Option: 2 x 12 V / 75 Ah 2 x 12 V / 110 Ah Max. battery dimensions in cm. Standard: Option: 26.5 x 17 x 22 28.4 x 26.

Medema Production A/S Own notes User guide P9-0135-B 47 of 52 Version 1.0.

Medema Production A/S International addresses Australia / New Zealand Germany Pride Mobility Products Tel: +61 3 9706-4611 Fax: +61 3 9706-4622 Email: prideaustralia@pride-mobility.com.au Internet: www.pridemobility.com/international/Australia/australia.asp Baden Württemberg Bavaria Draisin GmbH Tel: (+49) 0 78 41 66 77 0 Fax: (+49) 0 78 41 66 77 88 Email: info@draisin.com Internet: www.draisin.com/ Belgien Mobile Belgium Tel: +32 (0)50 317919 Fax: +32 (0)50 311026 Email: info@mobilescooter.

Medema Production A/S Holland Switzerland Richard van Seenus Nederland B.V. Tel: +31 (0) 36 53 20 450 Fax: +31 (0) 36 53 21 308 Email: info@vanseenus.nl Internet: www.vanseenus.nl Degonda Rehab SA Tel: +41 033 345 83 00 Fax: +41 033 345 83 01 Email: info@turbo-twist.ch Internet: www.turbo-twist.ch Island UK Icepharma HF Tel: +354 540 8000 Fax: +354 540 8001 Email: icepharma@icepharma.is Internet: www.icepharma.

Medema Production A/S User guide P9-0135-B 50 of 52 Version 1.0.

Medema Production A/S User guide P9-0135-B 51 of 52 Version 1.0.

medemagroup