Manual

19

The rotational orientation of the pins is critical. When reassembling the pins

it is important that the ‘split’ in the pins faces forward. (10mm & 460R units

have solid pins) After the pins have been driven out, the insert assembly is

free to be removed. Note in FIG.5 the various components involved. Take

care in removing the insert and note the position of these components. The

extractor spring can fall free after the insert has been removed from the

channel.

When the extractor pivot pin is removed the extractor falls free.

Note carefully how the extractor is oriented. The ‘claw’ faces in-

ward. The extractor has two small holes at one end. The rear-most

hole is larger and it is through this hole that the pivot pin must go

when reassembling. The smaller hole just forward of the pivot pin

hole is for the extractor spring. The short leg of the extractor spring

inserts into this hole while the longer leg points forward and lies

parallel to the extractor. When reassembling the insert into the bolt

channel be certain to correctly position the extractor spring as de-

scribed. The spring is caged by the bolt channel. After reassemby,

test the extractor function by pulling outward on the claw and note

that the claw returns when released. The action of the spring should

be evident.

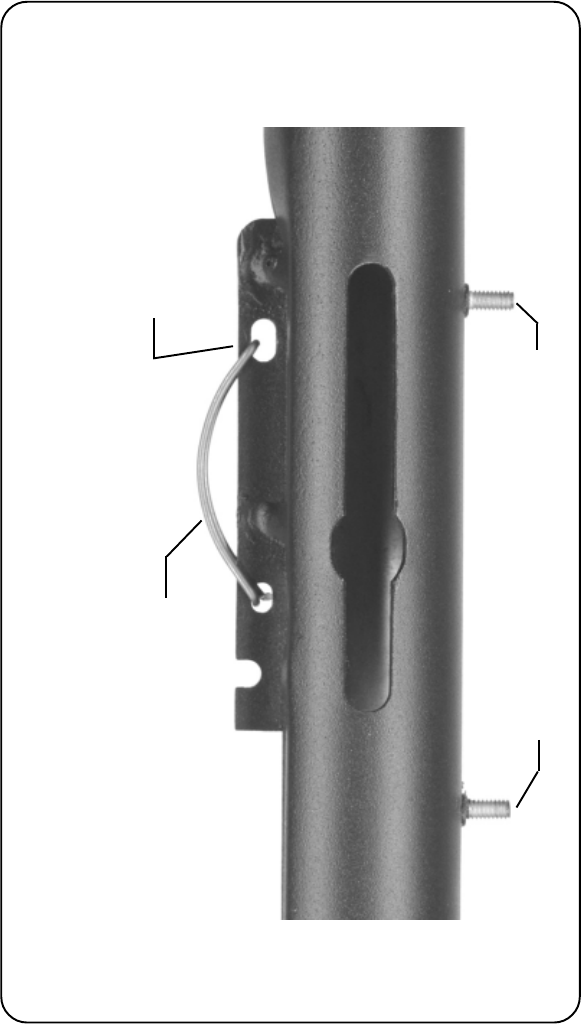

An extremely important component is the safety spring - see

FIG.9. This component is precision formed from steel spring wire.

It is a deceptively simple part considering the important role it plays

in the system. The spring is held in place by an ‘L’ bend at the front

end. The ‘L’ simply slips into a hole drilled in the bolt channel. As

shown in FIG.9 the spring is lying flat in the bolt channel with the

hairpin loop at the rear end surrounding a projection machined into

the channel. This is NOT the way it is when the channel is removed

from the unit - it is shown in FIG.9 lying flat for clarity as to how it

relates to the channel when the channel is installed in the main

housing. In reality the spring has a set in it such that when the ‘L’ is

in place in its’ hole the rear end hairpin loop is raised away from the

channel by about 1/2” - totally clearing the projection mentioned

above. Make certain to observe this when first dissasembling the

unit. The spring could actually fall free from the channel when the

channel is removed from the housing. Upon reassembly it is impor-

tant to position the spring with the loop engaging the projection as

shown in FIG.9 and hold it in this position while slipping the bolt/

barrel assembly (FIG.6) back into the housing. Once the channel is

in the housing the spring cannot escape. The function of this spring

is discussed in the ‘Operation’ section of this manual.

FIG. 10

MOUSETRAP SPRING

CLOSED END OF SPRING

RAIL MOUNTING THREADED STUDS

20