Instruction manual

Table Of Contents

- Introduction

- Using the Keypad/Display

- Keypad/Display Menu Structure

- System Summary Menu

- Standard Menus

- System Menu

- Occupancy Menu

- Temperature Menu

- Flow Summary Menu

- Supply Fan Speed Menu

- Return/Exhaust Fan Speed Menu

- Cooling Menu

- Head Pressure Menu

- Evap Condensing Menu

- Economizer Menu

- Min OA Damper Menu

- Heating Menu

- Energy Recovery

- Dehumidification Menu

- Daily Schedule Menu

- One Event Schedule Menu

- Holiday Schedule Menu

- Optimal Start Menu

- Operating Hours Menu

- Extended Menus

- Unit Setup Menu

- Timer Settings Menu

- Time/Date Menu

- Supply Fan Setup Menu

- Return/Exhaust Fan Setup Menu

- Zone Temperature Setup Menu

- Compressor Setup Menu

- Head Pressure Setup Menu

- Chilled Water Setup Menu

- Economizer Setup Menu

- Design Flow Setup Menu

- Heating Setup Menu

- Dehumidification Setup Menu

- Alarm Out Configuration Setup Menu

- Alarm Limits Setup Menu

- Manual Control Menu

- LON/BACnetIP/BACnetMSTP Setup Menu

- Active Alarm Menu

- Alarm Log Menu

- Advanced Menus

- Unit Configuration Setup Menu

- Save/Restore Menu

- Alarm Delays Setup Menu

- Analog Input Status Menu

- Universal I/O Status Menu

- Digital Input Status Menu

- Digital Output Status Menu

- Adv Setup Settings Menu

- Adv Status Parameters Menu

- Alarms

- Operator’s Guide

- Determining Unit State

- Off Operating State

- Start Up Operating State

- Recirculating Operating State

- Heating

- Economizer

- Mechanical Cooling

- Determining Unit Status

- Determining Control Mode

- Determining Cooling Status

- Determining Heat Status

- Determining Economizer Status

- Determining Cooling Capacity

- Determining Heating Capacity

- Determining Supply Air Fan Capacity

- Determining RF/EF Capacity

- Determining Outside Air Damper Position

- Determining Emergency Mode

- Determining Application Mode

- Determining Occupancy Status

- Determining Occupancy Mode

- Determining Occupancy Source

- Unoccupied Operation

- Scheduling

- Temperature Control Configurations

- Heat/Cool Changeover

- Dehumidification

- Energy Recovery

- Outside Air Damper Control

- Outside Air Damper Control, Two Position

- Special Procedures for Units with WRV and More Than Two Circuits.

- Water Pump Control

- Cooling: Multistage

- Cooling: Modulating

- Heating Control

- Modulating

- Min DAT

- Indoor Air Fan - On/Off Control

114 McQuay OM 920

Operator’s Guide

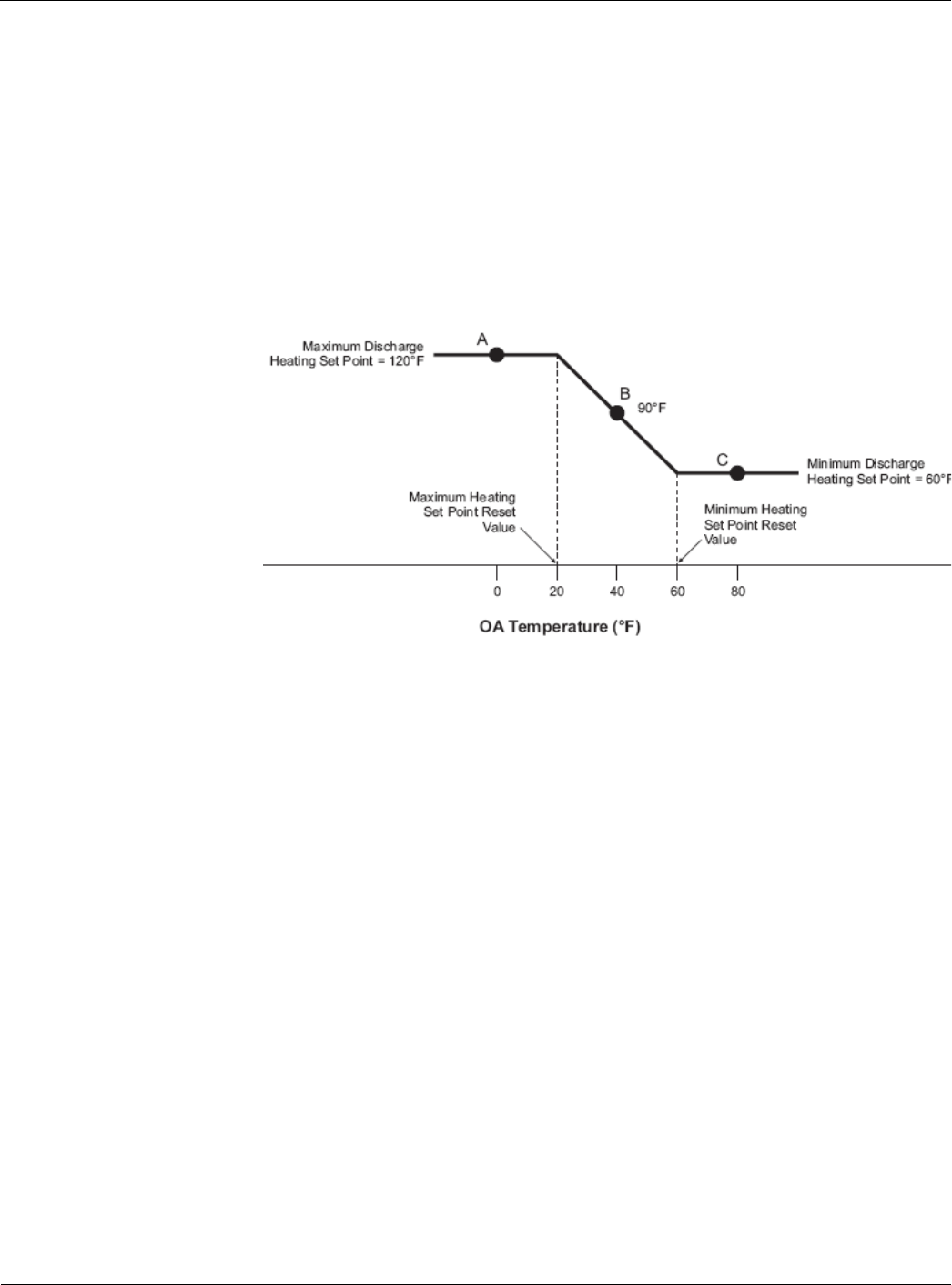

An example of discharge temperature reset based on outdoor air temperature is illustrated in

Figure 13 (Cooling Reset Type Flag is set to “OAT” in this example). When the current

outdoor air temperature is greater than or equal to the Minimum Cooling Set Point Reset Value

(90°F in this example), the Discharge Cooling Set Point is set equal to the Minimum

Discharge Cooling Set Point (55°F in this example). This is shown as Point C in Figure 13.

When the current outdoor air temperature is less than or equal to the

Maximum Cooling Set Point Reset Value (70°F in this example), the Discharge Cooling Set

Point is set equal to the Maximum Discharge Cooling Set Point (65°F in this example). This is

shown as Point A in Figure 13. When the current outdoor air temperature is between the

Minimum Cooling Set Point Reset Value and the Maximum Cooling Set Point Reset Value,

the Discharge Cooling Set Point varies linearly between the Minimum Discharge Cooling Set

Point and Maximum Discharge Cooling Set Point. This is shown as Point B in Figure 13.

Figure 13: Discharge Temperature Reset Based on Temperature

Indoor Air Fan - On/Off Control

A Supply fan is provided on every unit. That may be the only fan, but either a Return Fan or

an Exhaust Fan can be provided also. The start/stop signal and the speed signal for fans that

are controlled by variable frequency drives are provided via an internal ModBus network.

Constant volume Supply and Return fans are started and stopped through a digital output.

Exhaust Fans are always controlled by variable frequency drives.

Supply Fan

The Supply Fan is turned on when the unit enters the Recirculation state. The Supply Fan is

turned off when the unit transitions to the Off state, but it stays on for a OffHtClDelayTime

(Default- 120 seconds) if the unit is turned off while DX cooling or Staged heating is active.

The OffHtClDelayTime function is overridden when and Emergency Off or Duct High Limit

fault is active.

Return Fan

A Return fan driven by a variable frequency drive is started four seconds after the Supply Fan

is started to reduce the amp draw peak on startup. A constant volume Return Fan is turned on

through the same output as the Supply Fan. An external Fan Delay Relay is used to provide a

delay between startups if required.