Unit installation

Table Of Contents

- Introduction

- Installation

- Physical Data

- Electrical Data

- Dimensional Data

- Startup

- Operation

- Global UNT Controller Installation and Operation

- General Description

- Optional Sensors

- Sensors and Transducers

- Control Wiring

- External Voltage Inputs

- Interlock Wiring

- Unit Set Points and Calibration

- Optional Sensors

- Field Wiring

- Power Wiring

- Power Supplies

- Analog input signals

- Digital input signals

- Remote Stop/Start

- Chilled Water Flow Switch

- Digital Outputs

- External Alarm Annunciator Circuitry

- PC Connection

- Software Identification

- Controller Inputs /Outputs

- Additional Global UNT Features

- Alarms

- Zone Terminal (Optional)

- Zone Terminal Glossary

- UNT Troubleshooting Chart

- MicroTech Controller Installation and Operation

- Sensors and transducers

- Control wiring

- Remote 4-20 milliamp signals

- Interlock wiring

- Unit set points and calibration

- Modem kit

- Lead-Lag

- Field Wiring

- Power Wiring

- Power Supplies

- Analog Input Signals

- Digital Input Signals

- Remote Stop/Start

- Chilled Water Flow Switch

- Digital Outputs

- Chilled Water Pump Relay

- External Alarm Annunciator Circuitry

- PC Connection

- Telephone line

- Software Identification

- Controller Inputs /Outputs

- Reset Options

- Soft Loading

- Manual Operation

- Compressor Staging

- Head Pressure Control

- Pumpdown Control

- Safety Systems

- Circuit Alarm Conditions

- System Alarm Conditions

- Sequence of Operation

- Start-Up and Shutdown

- Keypad / Display

- Menu Descriptions

- Trouble Analysis for the MicroTech

- Test Procedures

- Unit Maintenance

- Service

70 AGZ 035A through 065A IOMM AGZ-3

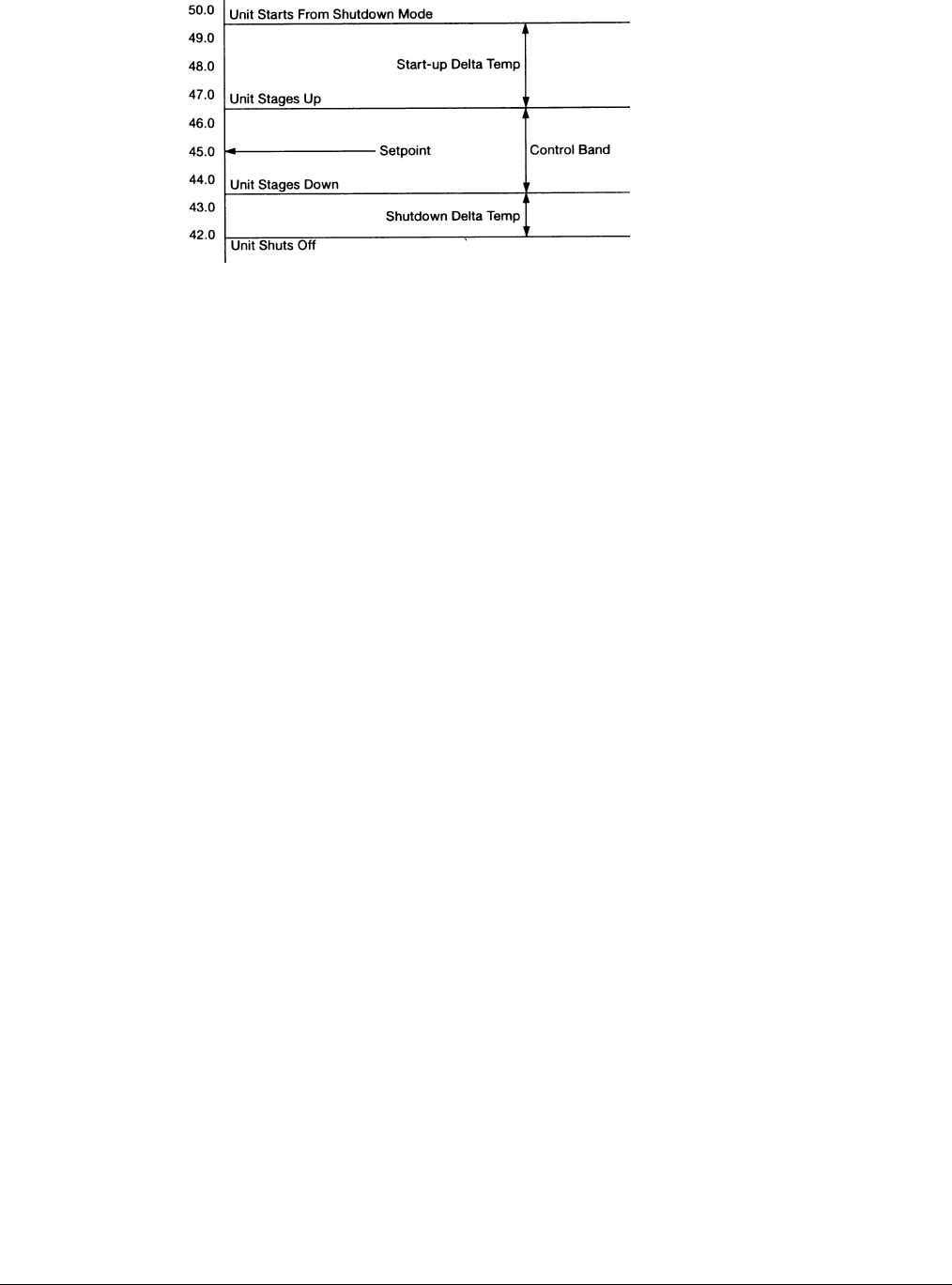

Figure 28, Delta-T Setpoints for Chillers

Menu #15: Softload Set Points—The controller can limit the number of available stages when the

unit is initially started to prevent excessive power consumption and help control overshoot of the

water temperature set point. The maximum number of stages will equal the Soft Load Maximum

Stages for the time period defined in the softload timer set point. If the softload timer is set to zero, no

soft loading will take place. Any time remaining in the softload timer will be displayed when the soft

load option is enabled. During morning start-up, the controller will run the chilled water pump and

sample the loop water temperature for a time equal to the Load Delay set point. If cooling or heating

is required at the end of this time delay, the first compressor will be started.

Menu #16: Compressor Set Points—This menu is used to set the lead-lag order of the refrigerant

circuits. The lead compressor can be manually set to circuit #1 or circuit #2 or the Automatic mode

can be enabled. In Automatic mode, the MicroTech controller will select the refrigerant circuit with

the lowest number starts as the lead. The interstage timer set point sets the delay time between the

current cooling stage and the next stage up request. The stage down request time delay is a fixed ratio

of the stage up delay.

The minimum Start/Start and Stop/Start timers provide protection against compressor short cycling.

During normal operation the Compressor Interstage Timers provide a time delay between cooling or

heating stages.

Menu #17: Head Pressure Set Points—The set points for head pressure control are adjusted from

within this menu. The Minimum Lift Pressure is the minimum differential pressure to be maintained

across the expansion valve. The dead band defines the pressure differential range within which no fan

staging will occur. If the head pressure moves outside of the deadband, the controller will integrate

the pressure error over time. When the Pound/Second exceeds the Stage Up Error or Stage Down

Error set point, the controller will adjust the fan staging up or down to bring the head pressure back

within the deadband. Refer to the section on head pressure control in this manual for details.

Menu #18: Demand Limit—The Demand Limit set point defines the maximum number of cooling

stages allowed by an external demand limit signal. The actual remote demand limit signal level in

milliamps is also displayed here.

In place of demand limit input, a 0 or 5 volts signal from a unit switch open or cool (5 volts - switch

closed) modes.

Menu #19: Time/Date—The MicroTech controller uses an internal calendar and clock to provide

automatic operation for each day of the year. Provision is made for Manual Override to accommodate

unscheduled building occupancy. Press the Control key to enter the control area of the menu structure

then press the Next Menu key until the display shows Menu Item #24, Set Date/Time. If the date is

incorrect, press the Incr or Decr key and the controller will prompt you for your password. When you

have entered the correct password, the controller will return to the Set Date/ Time display. Press the

Incr or Decr keys to scroll the month up or down. Press the Enter key when the display shows the

correct month. The cursor will advance to the Date position on the display that can be set in the same

manner. After pressing the Enter key to set the Date, the cursor will advance to the Year position on

the display. Use the Incr, Decr, and Enter keys to set the correct Year.