Unit installation

Table Of Contents

- Introduction

- Installation

- Physical Data

- Electrical Data

- Dimensional Data

- Startup

- Operation

- Global UNT Controller Installation and Operation

- General Description

- Optional Sensors

- Sensors and Transducers

- Control Wiring

- External Voltage Inputs

- Interlock Wiring

- Unit Set Points and Calibration

- Optional Sensors

- Field Wiring

- Power Wiring

- Power Supplies

- Analog input signals

- Digital input signals

- Remote Stop/Start

- Chilled Water Flow Switch

- Digital Outputs

- External Alarm Annunciator Circuitry

- PC Connection

- Software Identification

- Controller Inputs /Outputs

- Additional Global UNT Features

- Alarms

- Zone Terminal (Optional)

- Zone Terminal Glossary

- UNT Troubleshooting Chart

- MicroTech Controller Installation and Operation

- Sensors and transducers

- Control wiring

- Remote 4-20 milliamp signals

- Interlock wiring

- Unit set points and calibration

- Modem kit

- Lead-Lag

- Field Wiring

- Power Wiring

- Power Supplies

- Analog Input Signals

- Digital Input Signals

- Remote Stop/Start

- Chilled Water Flow Switch

- Digital Outputs

- Chilled Water Pump Relay

- External Alarm Annunciator Circuitry

- PC Connection

- Telephone line

- Software Identification

- Controller Inputs /Outputs

- Reset Options

- Soft Loading

- Manual Operation

- Compressor Staging

- Head Pressure Control

- Pumpdown Control

- Safety Systems

- Circuit Alarm Conditions

- System Alarm Conditions

- Sequence of Operation

- Start-Up and Shutdown

- Keypad / Display

- Menu Descriptions

- Trouble Analysis for the MicroTech

- Test Procedures

- Unit Maintenance

- Service

IOMM AGZ-3 AGZ 035A through 065A 11

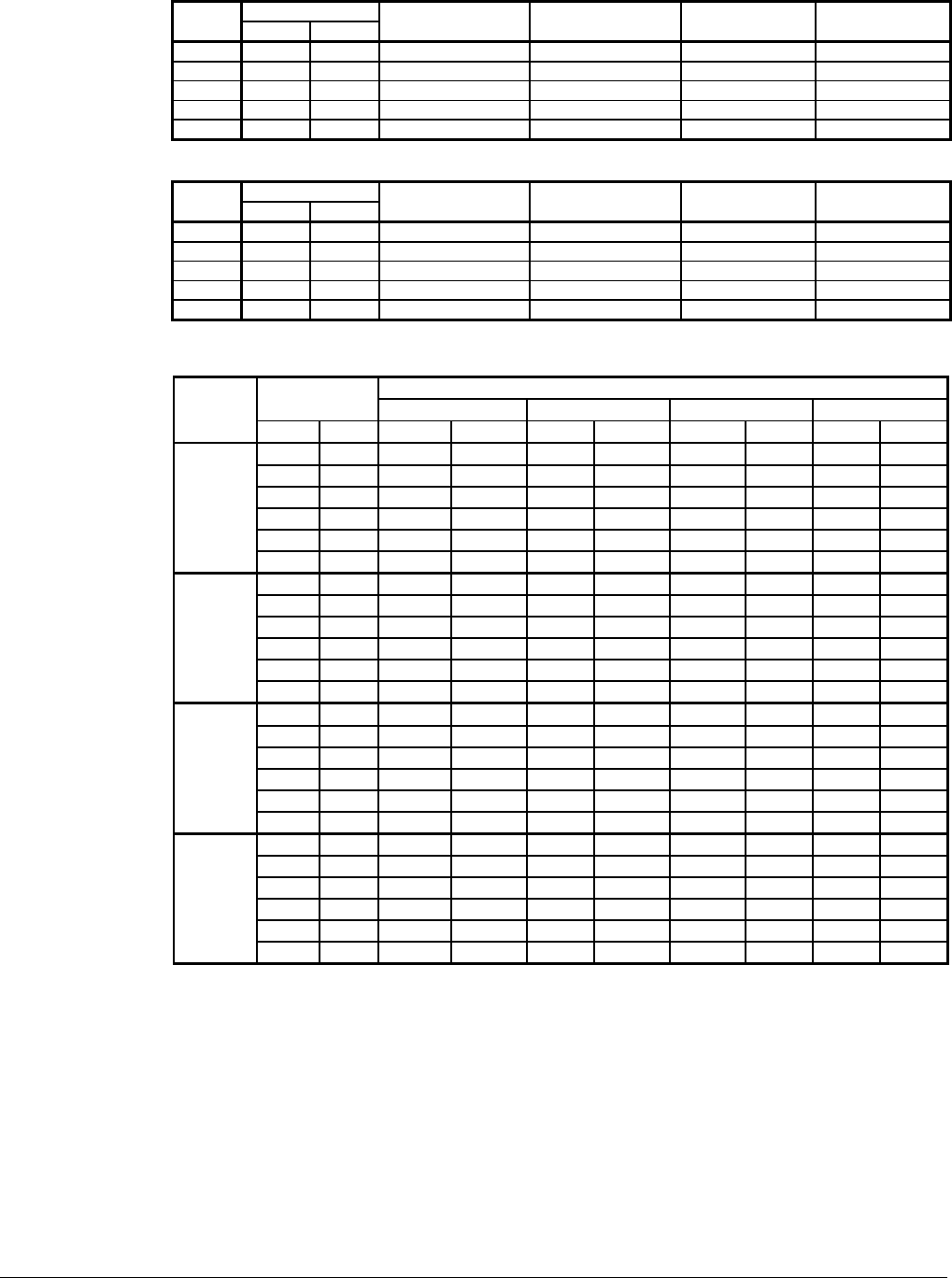

Table 4, Ethylene Glycol Correction Factors

Freeze Point

%

E.G.

°F °C

Capacity Power Flow Pressure Drop

10

26 -3 0.991 0.996 1.013 1.070

20

18 -8 0.982 0.992 1.040 1.129

30

7 -14 0.972 0.986 1.074 1.181

40

-7 -22 0.961 0.976 1.121 1.263

50

-28 -33 0.946 0.966 1.178 1.308

Table 5, Propylene Glycol Correction Factors

Freeze Point

%

P.G.

°F °C

Capacity Power Flow Pressure Drop

10

26 -3 0.987 0.992 1.010 1.068

20

19 -7 0.975 0.985 1.028 1.147

30

9 -13 0.962 0.978 1.050 1.248

40

-5 -21 0.946 0.971 1.078 1.366

50

-27 -33 0.929 0.965 1.116 1.481

Table 6, Capacity and Power Derates

Fouling Factor

Chilled Water

Delta-T

0.0001 (0.0176) 0.00025 (0.044) 0.00075 (0.132) 0.00175 (0.308)

ALTITUDE

°F °C Cap. Power Cap. Power Cap. Power Cap. Power

6 3.3 0.992 0.995 0.985 0.993 0.962 0.986 0.919 0.972

8 4.4 0.995 0.997 0.988 0.995 0.965 0.988 0.922 0.974

10 5.6 1.000 1.000 0.993 0.998 0.970 0.991 0.927 0.977

12 6.7 1.005 1.002 0.998 1.000 0.975 0.993 0.932 0.979

14 6.8 1.010 1.005 1.003 1.003 0.980 0.996 0.936 0.982

SEA

LEVEL

16 8.9 1.014 1.007 1.007 1.005 0.984 0.998 0.940 0.984

6 3.3 0.978 1.005 0.971 1.003 0.949 0.996 0.906 0.982

8 4.4 0.982 1.007 0.975 1.005 0.953 0.998 0.910 0.984

10 5.6 0.986 1.009 0.979 1.007 0.956 1.000 0.914 0.986

12 6.7 0.992 1.011 0.985 1.009 0.962 1.002 0.919 0.988

14 6.8 0.997 1.014 0.990 1.012 0.967 1.005 0.924 0.991

2000 feet

(610 m)

16 8.9 1.000 1.016 0.993 1.014 0.970 1.007 0.927 0.993

6 3.3 0.966 1.016 0.959 1.014 0.937 1.007 0.895 0.993

8 4.4 0.969 1.018 0.962 1.016 0.940 1.009 0.898 0.995

10 5.6 0.973 1.021 0.966 1.019 0.944 1.012 0.902 0.998

12 6.7 0.978 1.025 0.971 1.023 0.949 1.016 0.906 1.002

14 6.8 0.982 1.027 0.975 1.025 0.953 1.018 0.910 1.004

4000 feet

(1220 m)

16 8.9 0.986 1.028 0.979 1.026 0.956 1.019 0.914 1.005

6 3.3 0.953 1.025 0.946 1.023 0.924 1.016 0.883 1.002

8 4.4 0.955 1.028 0.948 1.026 0.926 1.019 0.885 1.005

10 5.6 0.959 1.031 0.952 1.029 0.930 1.022 0.889 1.008

12 6.7 0.963 1.034 0.956 1.032 0.934 1.024 0.893 1.011

14 6.8 0.968 1.036 0.961 1.034 0.939 1.026 0.897 1.013

6000 feet

(1830 m)

16 8.9 0.972 1.037 0.965 1.035 0.943 1.027 0.901 1.014

Evaporator Flow and Pressure Drop

Evaporator flow rate must fall between the minimum and maximum values shown in the evaporator

pressure drop table on Figure 7.

Measure the chilled water pressure drop through the evaporator at factory installed pressure taps. It is

important not to include the effect of valves or strainers in these readings.

Varying chilled water flow through the evaporator while the compressor(s) are operating is not

recommended.