Instruction manual

/

radio receiver’s throttle channel; switch ON your transmitter and set transmitter’s throttle and throttle

trim controls to minimum; with no propeller on the motor, switch ON your transmitter and connect

the ESC to the battery; after you hear a series of initialization sounds, slowly raise the transmitter’s

throttle to no more than 25% of maximum.

d) Carefully run the motor slowly and only for the few seconds necessary to observe its direction of

rotation. If the motor rotated in the clockwise (correct) direction as viewed from the rear of the

airplane, return the throttle to minimum, disconnect the ESC from the battery, switch OFF the

transmitter, and set your battery and transmitter aside. If the motor powered up in

the counterclockwise (wrong) direction, return the throttle control to minimum,

disconnect the ESC from the battery, swap either two of the three ESC-to-motor

wires, and repeat the above procedure to ensure the motor rotates in the correct

direction.

j. If you are installing the optional dummy engine, use epoxy and/or wood screws to

attach the mounting plates 1 3/4-inch above the bottom edges and close the side edge

of the cowl.

k. Position the cowl so the propeller backplate protrudes approx. 1/4 inch beyond the

face of the cowl; use low-tack masking tape to temporarily hold the cowl in position;

use the provided 5/16-inch screws to attach the cowl; and remove the masking tape.

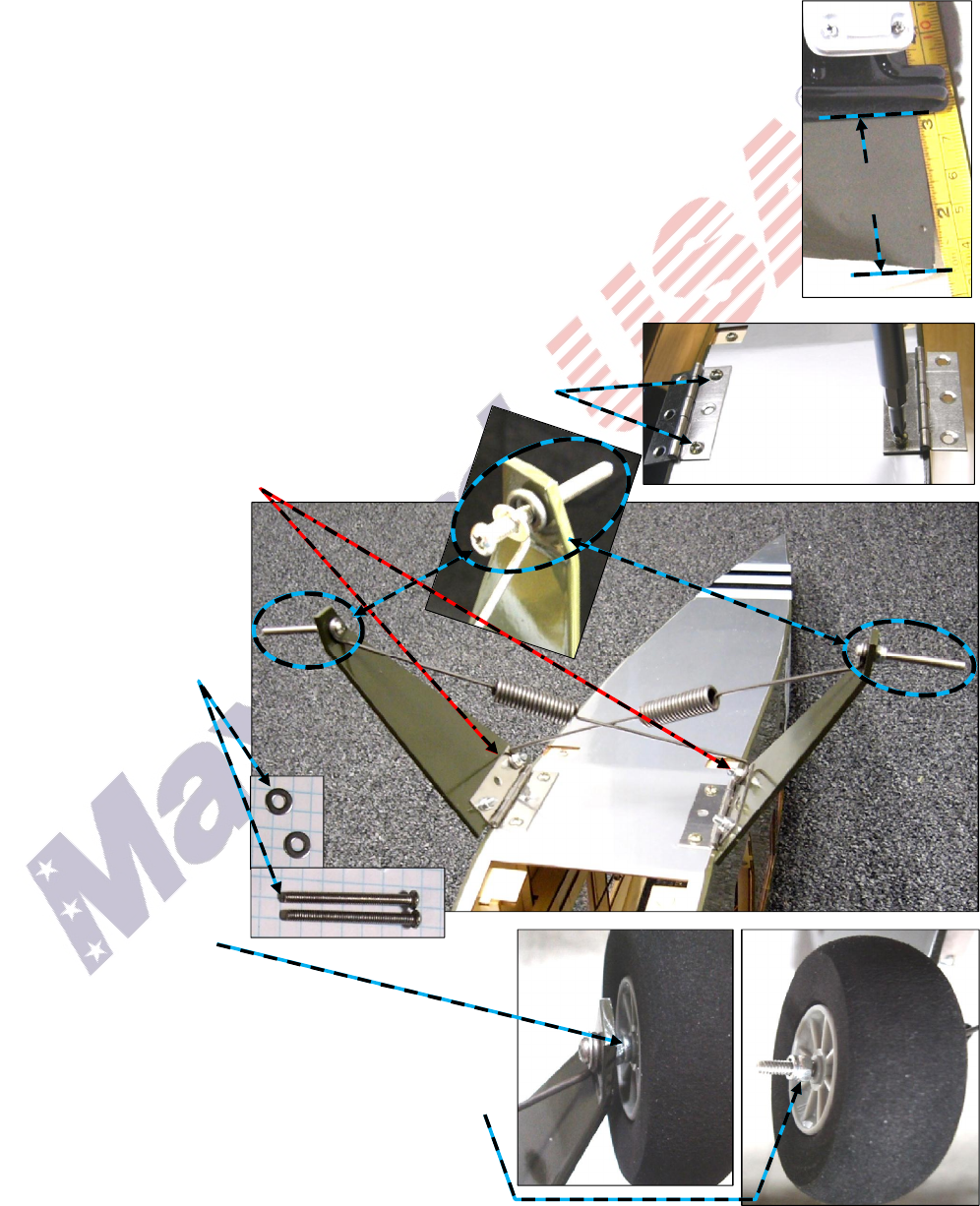

3. Main Landing Gear –

(NOTE: If you are using floats, replace this section with the detailed

instructions included with the floats.)

a. As shown at the right, turn the fuselage upside down and attach the

hinges by driving two bolts into the preinstalled blind nuts.

b. Use two bolts and self-locking nuts to attach each

landing gear strut to its hinge. Place one end of an

8-inch long spring under the two rearmost self-

locking nuts.

c. If necessary, bend the

spring’s ends so the

straight portion of the

spring ‘points’ toward

the opposing axle.

d. Place flat washers

on two 1 1/2-inch

long bolts. Insert a

bolt through the free

end of each spring,

guide the bolts into

and through the holes

in the ends of the

main gear struts.

e. Use a self-locking nut

to secure the bolts and

springs to the struts.

f. Place a wheel onto the

end of each 1 1/2-inch long bolt

and use a self-locking nut to hold each wheel

onto its axle.

g. Apply a drop of CA adhesive to ensure each wheel is

secured to its axle. (You may also choose to use a

rotary tool with a cutting wheel to remove and

discard the excess length of each bolt/axle.)

Page 6 of 14

S121015 Copyright 2012

Approx.

1 3/4 inch

(

1/4

-

inch squares)