User`s guide

Table Of Contents

- Preface

- Quick Start

- LTI Models

- Introduction

- Creating LTI Models

- LTI Properties

- Model Conversion

- Time Delays

- Simulink Block for LTI Systems

- References

- Operations on LTI Models

- Arrays of LTI Models

- Model Analysis Tools

- The LTI Viewer

- Introduction

- Getting Started Using the LTI Viewer: An Example

- The LTI Viewer Menus

- The Right-Click Menus

- The LTI Viewer Tools Menu

- Simulink LTI Viewer

- Control Design Tools

- The Root Locus Design GUI

- Introduction

- A Servomechanism Example

- Controller Design Using the Root Locus Design GUI

- Additional Root Locus Design GUI Features

- References

- Design Case Studies

- Reliable Computations

- Reference

- Category Tables

- acker

- append

- augstate

- balreal

- bode

- c2d

- canon

- care

- chgunits

- connect

- covar

- ctrb

- ctrbf

- d2c

- d2d

- damp

- dare

- dcgain

- delay2z

- dlqr

- dlyap

- drmodel, drss

- dsort

- dss

- dssdata

- esort

- estim

- evalfr

- feedback

- filt

- frd

- frdata

- freqresp

- gensig

- get

- gram

- hasdelay

- impulse

- initial

- inv

- isct, isdt

- isempty

- isproper

- issiso

- kalman

- kalmd

- lft

- lqgreg

- lqr

- lqrd

- lqry

- lsim

- ltiview

- lyap

- margin

- minreal

- modred

- ndims

- ngrid

- nichols

- norm

- nyquist

- obsv

- obsvf

- ord2

- pade

- parallel

- place

- pole

- pzmap

- reg

- reshape

- rlocfind

- rlocus

- rltool

- rmodel, rss

- series

- set

- sgrid

- sigma

- size

- sminreal

- ss

- ss2ss

- ssbal

- ssdata

- stack

- step

- tf

- tfdata

- totaldelay

- zero

- zgrid

- zpk

- zpkdata

- Index

2 LTI Models

2-48

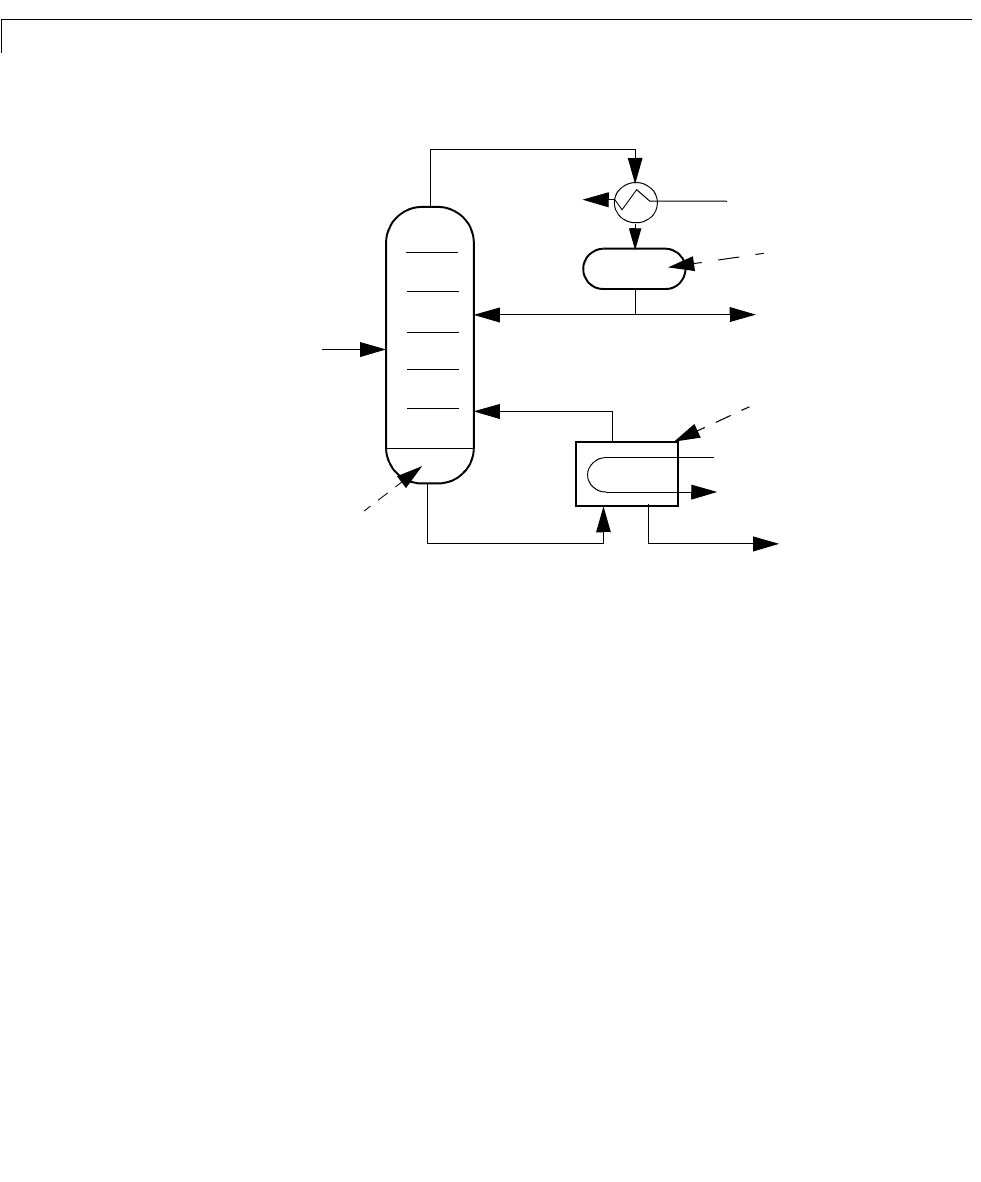

Figure 2-3: Distillation Column

Schematica lly, t he dis tillat io n p rocess functions as follo ws:

• Stea m flow s into the reb oil er and vapo rizes the bot tom li quid. This vapo r is

reinjecte d into the co lu mn and mixes with the feed

• Methanol, being more volatile than water, tends to concentrate in the vapor

moving upward. Meanwhile, water t ends to flow downward a nd accumulate

as the bott om l iquid

• The vapor exiting at t he to p of t he co lumn is condensed by a flow o f coo li ng

water. Part of this co ndens ed vapor is extra c ted as the distillat e, and the rest

of th e condensate (th e reflux) is sent back to the column.

• Part of the bo ttom liquid is colle cte d f rom the reboil er a s b ot to m p rodu ct s

(waste).

Feed

Enriched vapor

Cooling water

Condensate

Reflux

Distillate

Vapor

Steam flow

Reboiler

Bottom liq uid

Bottom products