User`s guide

Table Of Contents

- Preface

- Quick Start

- LTI Models

- Introduction

- Creating LTI Models

- LTI Properties

- Model Conversion

- Time Delays

- Simulink Block for LTI Systems

- References

- Operations on LTI Models

- Arrays of LTI Models

- Model Analysis Tools

- The LTI Viewer

- Introduction

- Getting Started Using the LTI Viewer: An Example

- The LTI Viewer Menus

- The Right-Click Menus

- The LTI Viewer Tools Menu

- Simulink LTI Viewer

- Control Design Tools

- The Root Locus Design GUI

- Introduction

- A Servomechanism Example

- Controller Design Using the Root Locus Design GUI

- Additional Root Locus Design GUI Features

- References

- Design Case Studies

- Reliable Computations

- Reference

- Category Tables

- acker

- append

- augstate

- balreal

- bode

- c2d

- canon

- care

- chgunits

- connect

- covar

- ctrb

- ctrbf

- d2c

- d2d

- damp

- dare

- dcgain

- delay2z

- dlqr

- dlyap

- drmodel, drss

- dsort

- dss

- dssdata

- esort

- estim

- evalfr

- feedback

- filt

- frd

- frdata

- freqresp

- gensig

- get

- gram

- hasdelay

- impulse

- initial

- inv

- isct, isdt

- isempty

- isproper

- issiso

- kalman

- kalmd

- lft

- lqgreg

- lqr

- lqrd

- lqry

- lsim

- ltiview

- lyap

- margin

- minreal

- modred

- ndims

- ngrid

- nichols

- norm

- nyquist

- obsv

- obsvf

- ord2

- pade

- parallel

- place

- pole

- pzmap

- reg

- reshape

- rlocfind

- rlocus

- rltool

- rmodel, rss

- series

- set

- sgrid

- sigma

- size

- sminreal

- ss

- ss2ss

- ssbal

- ssdata

- stack

- step

- tf

- tfdata

- totaldelay

- zero

- zgrid

- zpk

- zpkdata

- Index

9 Design Case Studies

9-38

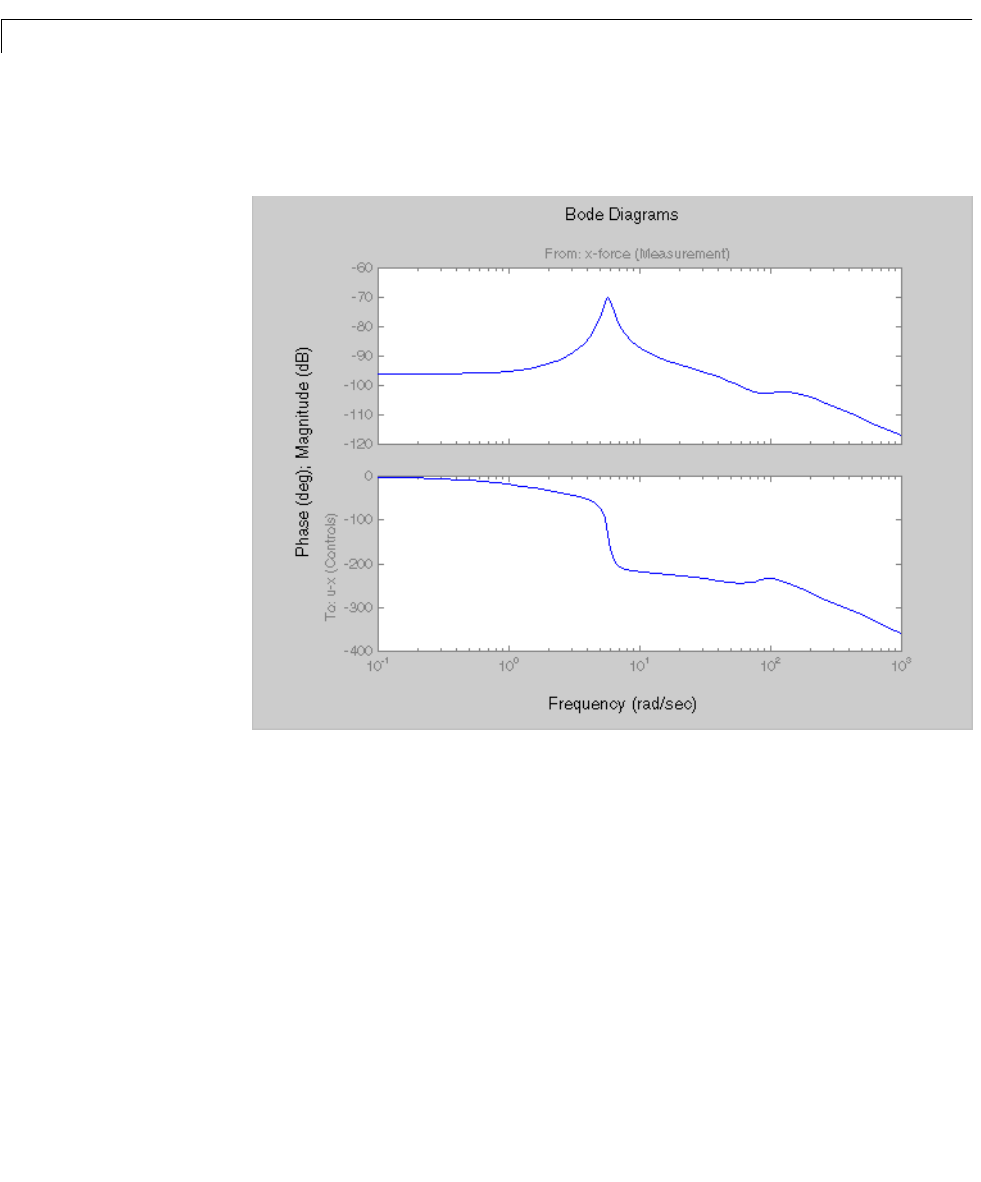

Let’s look at the regulator Bode response between 0.1 and 1000 rad/sec.

bode(Regx,{0.1 1000})

The phase response has an interesting physical interpretation. First, consider

an increase in input thickness. This low-frequency disturbance boosts both

output thickness and rolling force. Because the regulator phase is

approximately 0

o

at low frequencies, the feedback loop then adequately reacts

by increasing the hy draulic force to offset the thickness increase. N ow consider

the effect of eccentricity. Eccentricity causes fluctuations in the roll gap (gap

between the rolling cylinders). When the roll gap is minimal, the rolling force

increases and the beam thickness diminishes. The hydraulic force must then

be reduced (negative force feedback) to restore the desired thickness. This is

exactly what the LQG regulator does as its phase drops to –180

o

near the

natural frequency of the eccentricit y disturbance (6 rad/sec).