Specifications

Table Of Contents

- Introduction

- LTI Models

- Operations on LTI Models

- Model Analysis Tools

- Arrays of LTI Models

- Customization

- Setting Toolbox Preferences

- Setting Tool Preferences

- Customizing Response Plot Properties

- Design Case Studies

- Reliable Computations

- GUI Reference

- SISO Design Tool Reference

- Menu Bar

- File

- Import

- Export

- Toolbox Preferences

- Print to Figure

- Close

- Edit

- Undo and Redo

- Root Locus and Bode Diagrams

- SISO Tool Preferences

- View

- Root Locus and Bode Diagrams

- System Data

- Closed Loop Poles

- Design History

- Tools

- Loop Responses

- Continuous/Discrete Conversions

- Draw a Simulink Diagram

- Compensator

- Format

- Edit

- Store

- Retrieve

- Clear

- Window

- Help

- Tool Bar

- Current Compensator

- Feedback Structure

- Root Locus Right-Click Menus

- Bode Diagram Right-Click Menus

- Status Panel

- Menu Bar

- LTI Viewer Reference

- Right-Click Menus for Response Plots

- Function Reference

- Functions by Category

- acker

- allmargin

- append

- augstate

- balreal

- bode

- bodemag

- c2d

- canon

- care

- chgunits

- connect

- covar

- ctrb

- ctrbf

- d2c

- d2d

- damp

- dare

- dcgain

- delay2z

- dlqr

- dlyap

- drss

- dsort

- dss

- dssdata

- esort

- estim

- evalfr

- feedback

- filt

- frd

- frdata

- freqresp

- gensig

- get

- gram

- hasdelay

- impulse

- initial

- interp

- inv

- isct, isdt

- isempty

- isproper

- issiso

- kalman

- kalmd

- lft

- lqgreg

- lqr

- lqrd

- lqry

- lsim

- ltimodels

- ltiprops

- ltiview

- lyap

- margin

- minreal

- modred

- ndims

- ngrid

- nichols

- norm

- nyquist

- obsv

- obsvf

- ord2

- pade

- parallel

- place

- pole

- pzmap

- reg

- reshape

- rlocus

- rss

- series

- set

- sgrid

- sigma

- sisotool

- size

- sminreal

- ss

- ss2ss

- ssbal

- ssdata

- stack

- step

- tf

- tfdata

- totaldelay

- zero

- zgrid

- zpk

- zpkdata

- Index

2 LTI Models

2-46

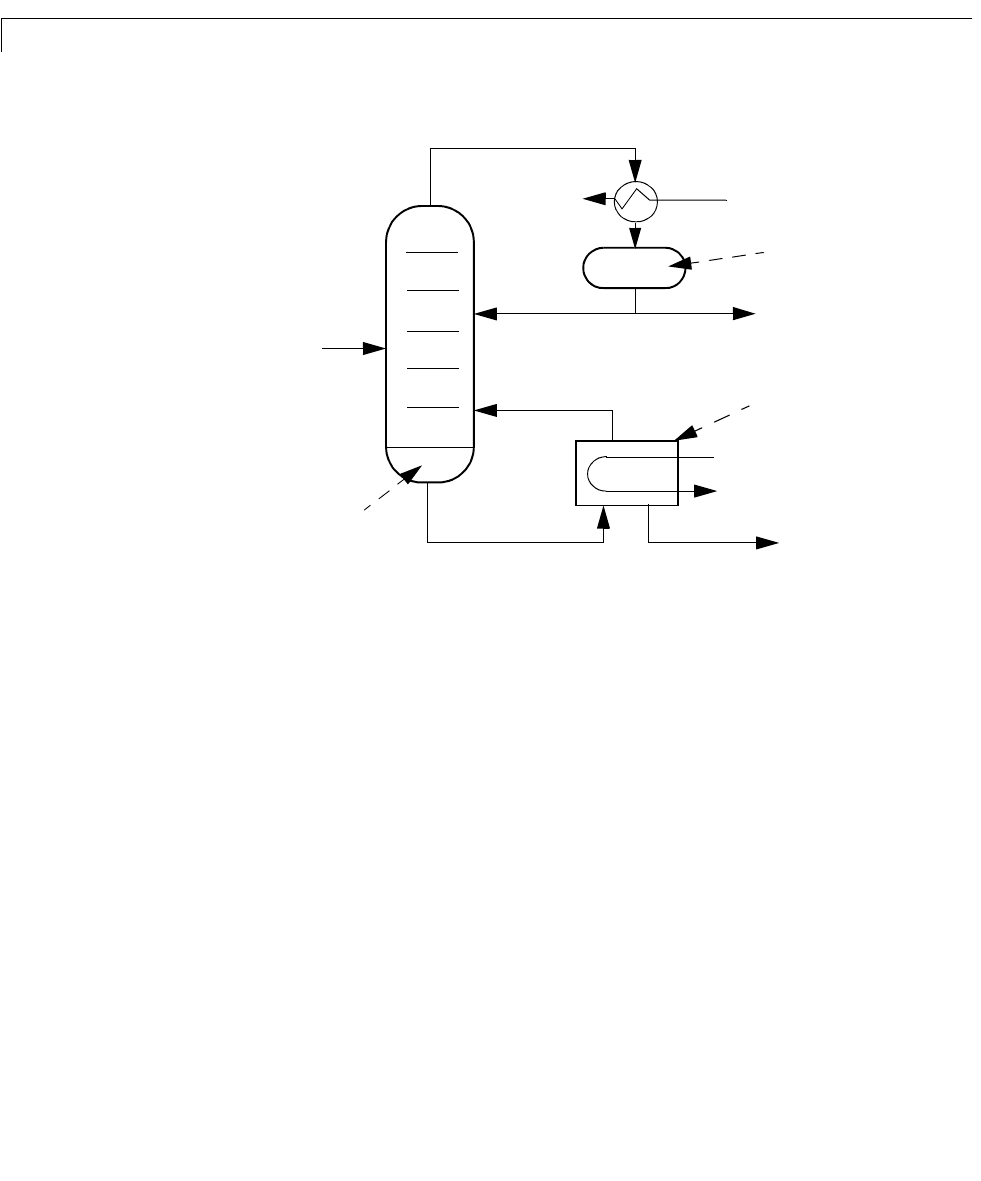

Figure 2-3: Distillation Column

Schematically, the distillation process functions as follows:

•Steam flows into the reboiler and vaporizes the bottom liquid. This vapor is

reinjected into the column and mixes with the feed

•Methanol, being more volatile than water, tends to concentrate in the vapor

moving upward. Meanwhile, water tends to flow downward and accumulate

as the bottom liquid

•The vapor exiting at the top of the column is condensed by a flow of cooling

water. Part of this condensed vapor is extracted as the distillate, and the rest

ofthecondensate(thereflux) is sent back to the column.

•Part of the bottom liquid is collected from the reboiler as bottom products

(waste).

The regulated output variables are:

•Percentage of methanol in the distillate

•Percentage of methanol in the bottom products.

Feed

Enriched vapor

Cooling water

Condensate

Reflux

Distillate

Vapor

Steam flow

Reboiler

Bottom liquid

Bottom products

X

D

X

B