Specifications

Table Of Contents

- Introduction

- LTI Models

- Operations on LTI Models

- Model Analysis Tools

- Arrays of LTI Models

- Customization

- Setting Toolbox Preferences

- Setting Tool Preferences

- Customizing Response Plot Properties

- Design Case Studies

- Reliable Computations

- GUI Reference

- SISO Design Tool Reference

- Menu Bar

- File

- Import

- Export

- Toolbox Preferences

- Print to Figure

- Close

- Edit

- Undo and Redo

- Root Locus and Bode Diagrams

- SISO Tool Preferences

- View

- Root Locus and Bode Diagrams

- System Data

- Closed Loop Poles

- Design History

- Tools

- Loop Responses

- Continuous/Discrete Conversions

- Draw a Simulink Diagram

- Compensator

- Format

- Edit

- Store

- Retrieve

- Clear

- Window

- Help

- Tool Bar

- Current Compensator

- Feedback Structure

- Root Locus Right-Click Menus

- Bode Diagram Right-Click Menus

- Status Panel

- Menu Bar

- LTI Viewer Reference

- Right-Click Menus for Response Plots

- Function Reference

- Functions by Category

- acker

- allmargin

- append

- augstate

- balreal

- bode

- bodemag

- c2d

- canon

- care

- chgunits

- connect

- covar

- ctrb

- ctrbf

- d2c

- d2d

- damp

- dare

- dcgain

- delay2z

- dlqr

- dlyap

- drss

- dsort

- dss

- dssdata

- esort

- estim

- evalfr

- feedback

- filt

- frd

- frdata

- freqresp

- gensig

- get

- gram

- hasdelay

- impulse

- initial

- interp

- inv

- isct, isdt

- isempty

- isproper

- issiso

- kalman

- kalmd

- lft

- lqgreg

- lqr

- lqrd

- lqry

- lsim

- ltimodels

- ltiprops

- ltiview

- lyap

- margin

- minreal

- modred

- ndims

- ngrid

- nichols

- norm

- nyquist

- obsv

- obsvf

- ord2

- pade

- parallel

- place

- pole

- pzmap

- reg

- reshape

- rlocus

- rss

- series

- set

- sgrid

- sigma

- sisotool

- size

- sminreal

- ss

- ss2ss

- ssbal

- ssdata

- stack

- step

- tf

- tfdata

- totaldelay

- zero

- zgrid

- zpk

- zpkdata

- Index

10 Design Case Studies

10-38

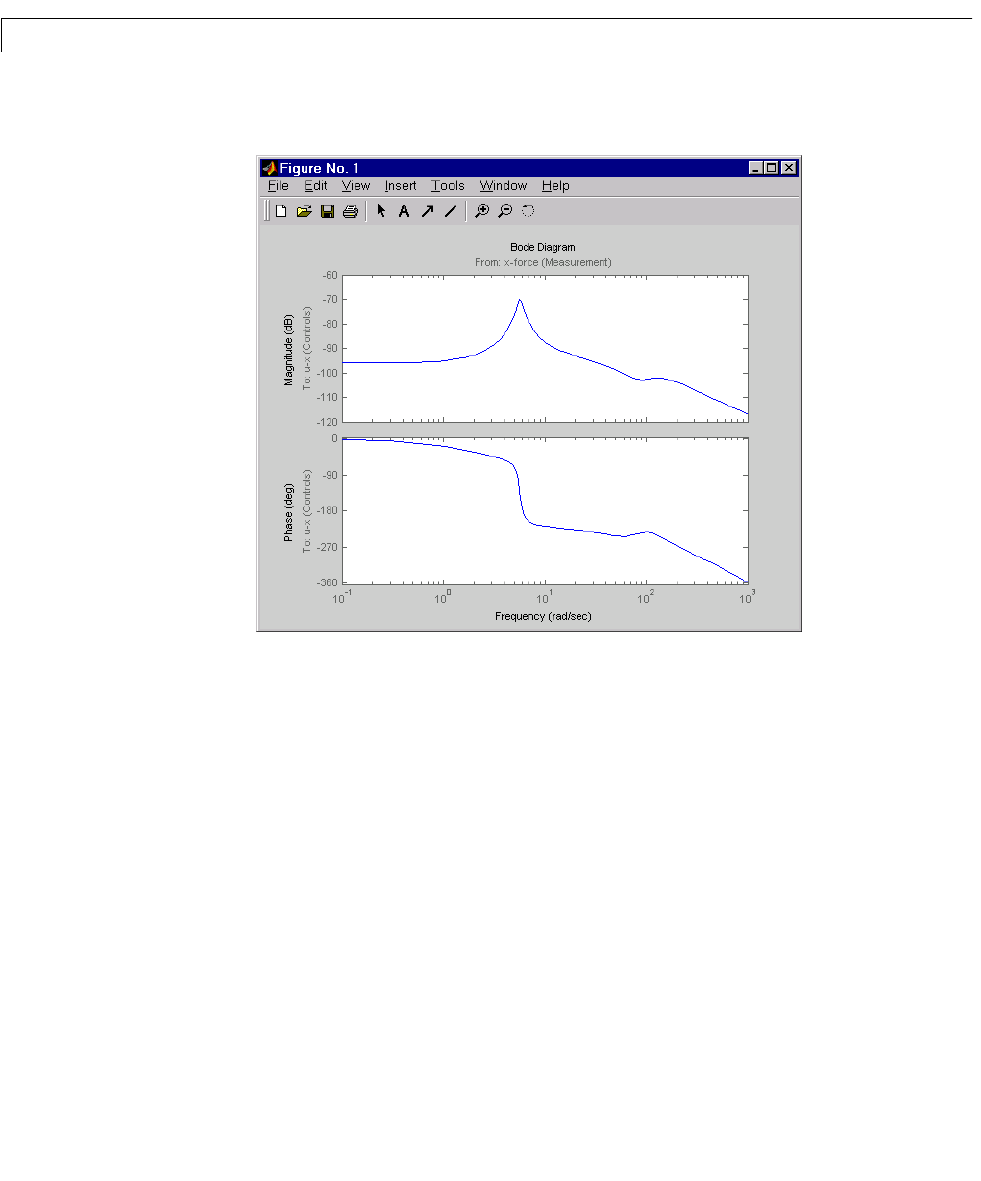

bode(Regx,{0.1 1000})

The phase response has an interesting physical interpretation. First, consider

an increase in input thickness. This low-frequency disturbance boosts both

output thickness and rolling force. Because the regulator phase is

approximately 0

o

at low frequencies, the feedback loop then adequately reacts

by increasing thehydraulic forceto offset the thickness increase. Now consider

the effect of eccentricity. Eccentricity causes fluctuations in the roll gap (gap

between the rolling cylinders). When the roll gap is minimal, the rolling force

increases and the beam thickness diminishes. The hydraulic force must then

be reduced (negative force feedback) to restore the desired thickness. This is

exactly what the LQG regulator does as its phase drops to -180

o

near the

natural frequency of the eccentricity disturbance (6 rad/sec).

Next, compare the open- and closed-loop responses from disturbance to

thickness gap. Use

feedback to close the loop. To help specify the feedback

connection, look at the I/O names of the plant

Px and regulator Regx.

Px.inputname

ans =