Specifications

Table Of Contents

- Introduction

- LTI Models

- Operations on LTI Models

- Model Analysis Tools

- Arrays of LTI Models

- Customization

- Setting Toolbox Preferences

- Setting Tool Preferences

- Customizing Response Plot Properties

- Design Case Studies

- Reliable Computations

- GUI Reference

- SISO Design Tool Reference

- Menu Bar

- File

- Import

- Export

- Toolbox Preferences

- Print to Figure

- Close

- Edit

- Undo and Redo

- Root Locus and Bode Diagrams

- SISO Tool Preferences

- View

- Root Locus and Bode Diagrams

- System Data

- Closed Loop Poles

- Design History

- Tools

- Loop Responses

- Continuous/Discrete Conversions

- Draw a Simulink Diagram

- Compensator

- Format

- Edit

- Store

- Retrieve

- Clear

- Window

- Help

- Tool Bar

- Current Compensator

- Feedback Structure

- Root Locus Right-Click Menus

- Bode Diagram Right-Click Menus

- Status Panel

- Menu Bar

- LTI Viewer Reference

- Right-Click Menus for Response Plots

- Function Reference

- Functions by Category

- acker

- allmargin

- append

- augstate

- balreal

- bode

- bodemag

- c2d

- canon

- care

- chgunits

- connect

- covar

- ctrb

- ctrbf

- d2c

- d2d

- damp

- dare

- dcgain

- delay2z

- dlqr

- dlyap

- drss

- dsort

- dss

- dssdata

- esort

- estim

- evalfr

- feedback

- filt

- frd

- frdata

- freqresp

- gensig

- get

- gram

- hasdelay

- impulse

- initial

- interp

- inv

- isct, isdt

- isempty

- isproper

- issiso

- kalman

- kalmd

- lft

- lqgreg

- lqr

- lqrd

- lqry

- lsim

- ltimodels

- ltiprops

- ltiview

- lyap

- margin

- minreal

- modred

- ndims

- ngrid

- nichols

- norm

- nyquist

- obsv

- obsvf

- ord2

- pade

- parallel

- place

- pole

- pzmap

- reg

- reshape

- rlocus

- rss

- series

- set

- sgrid

- sigma

- sisotool

- size

- sminreal

- ss

- ss2ss

- ssbal

- ssdata

- stack

- step

- tf

- tfdata

- totaldelay

- zero

- zgrid

- zpk

- zpkdata

- Index

LQG Regulation: Rolling Mill Example

10-33

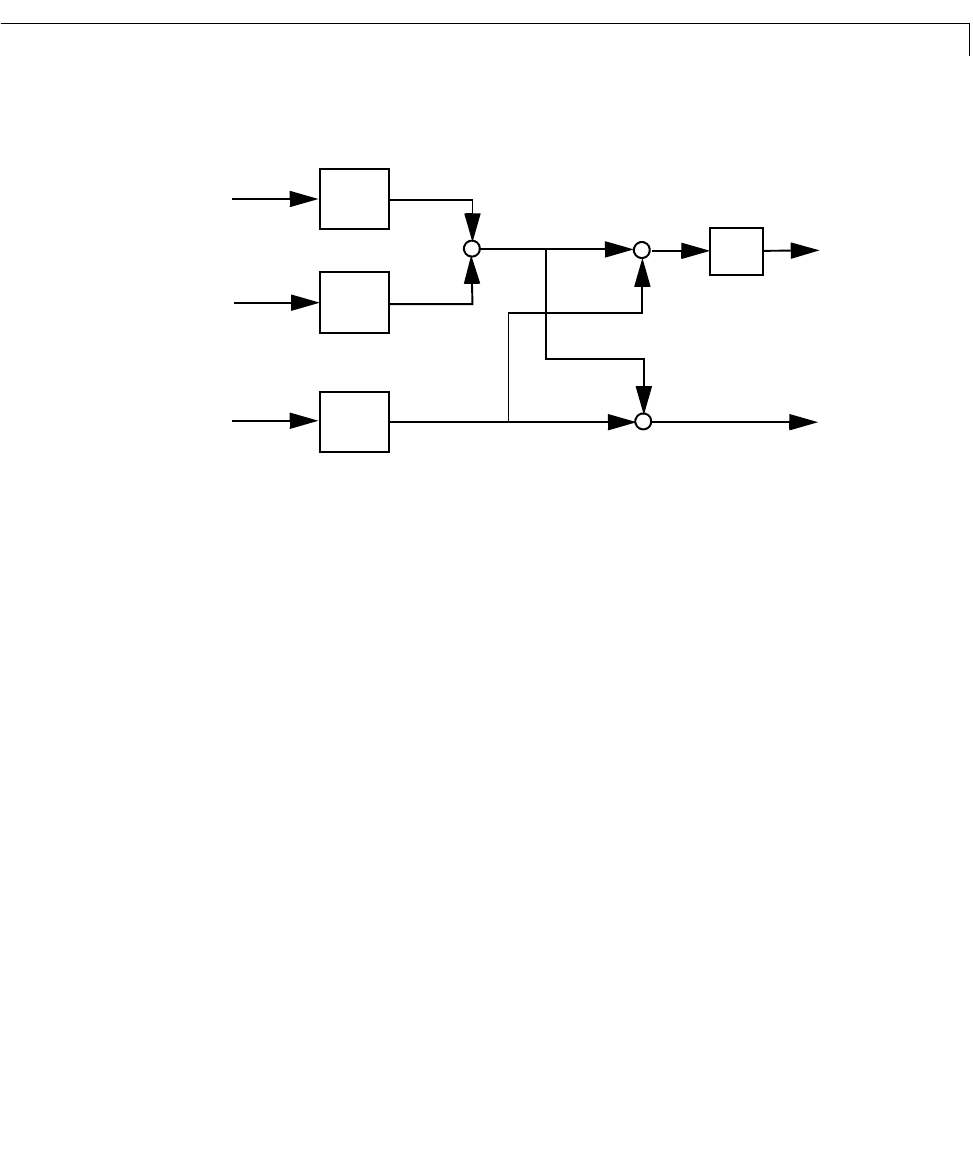

This leads to the following generic model for each axis of the rolling process.

Figure 10-1: Open-loop model for x- or y-axis

The measured rolling force variation is a combination of the incremental

force delivered by the hydraulic actuator and of the disturbance forces due to

eccentricity and input thickness variation. Note that:

•The outputs of , and are the incremental forces delivered

by each component.

•An increase in hydraulic or eccentricity force reduces the output thickness

gap .

•An increase in input thickness increases this gap.

The model data for each axis is summarized below.

hydraulic actuator

eccentricity model

+

+

–

input disturbance model

+

+

+

Hs

()

F

i

s

()

F

e

s

()

δ

w

i

w

e

u

g

x

f

u command

δ

thickness gap (in mm)

f incremental rolling force

w

i

w

e

,

driving white noise for disturbance models

f

2

f

1

force-to-gap gain

f

Hs

()

F

e

s

(),

F

i

s

()

δ