Specifications

Table Of Contents

- Introduction

- LTI Models

- Operations on LTI Models

- Model Analysis Tools

- Arrays of LTI Models

- Customization

- Setting Toolbox Preferences

- Setting Tool Preferences

- Customizing Response Plot Properties

- Design Case Studies

- Reliable Computations

- GUI Reference

- SISO Design Tool Reference

- Menu Bar

- File

- Import

- Export

- Toolbox Preferences

- Print to Figure

- Close

- Edit

- Undo and Redo

- Root Locus and Bode Diagrams

- SISO Tool Preferences

- View

- Root Locus and Bode Diagrams

- System Data

- Closed Loop Poles

- Design History

- Tools

- Loop Responses

- Continuous/Discrete Conversions

- Draw a Simulink Diagram

- Compensator

- Format

- Edit

- Store

- Retrieve

- Clear

- Window

- Help

- Tool Bar

- Current Compensator

- Feedback Structure

- Root Locus Right-Click Menus

- Bode Diagram Right-Click Menus

- Status Panel

- Menu Bar

- LTI Viewer Reference

- Right-Click Menus for Response Plots

- Function Reference

- Functions by Category

- acker

- allmargin

- append

- augstate

- balreal

- bode

- bodemag

- c2d

- canon

- care

- chgunits

- connect

- covar

- ctrb

- ctrbf

- d2c

- d2d

- damp

- dare

- dcgain

- delay2z

- dlqr

- dlyap

- drss

- dsort

- dss

- dssdata

- esort

- estim

- evalfr

- feedback

- filt

- frd

- frdata

- freqresp

- gensig

- get

- gram

- hasdelay

- impulse

- initial

- interp

- inv

- isct, isdt

- isempty

- isproper

- issiso

- kalman

- kalmd

- lft

- lqgreg

- lqr

- lqrd

- lqry

- lsim

- ltimodels

- ltiprops

- ltiview

- lyap

- margin

- minreal

- modred

- ndims

- ngrid

- nichols

- norm

- nyquist

- obsv

- obsvf

- ord2

- pade

- parallel

- place

- pole

- pzmap

- reg

- reshape

- rlocus

- rss

- series

- set

- sgrid

- sigma

- sisotool

- size

- sminreal

- ss

- ss2ss

- ssbal

- ssdata

- stack

- step

- tf

- tfdata

- totaldelay

- zero

- zgrid

- zpk

- zpkdata

- Index

10 Design Case Studies

10-32

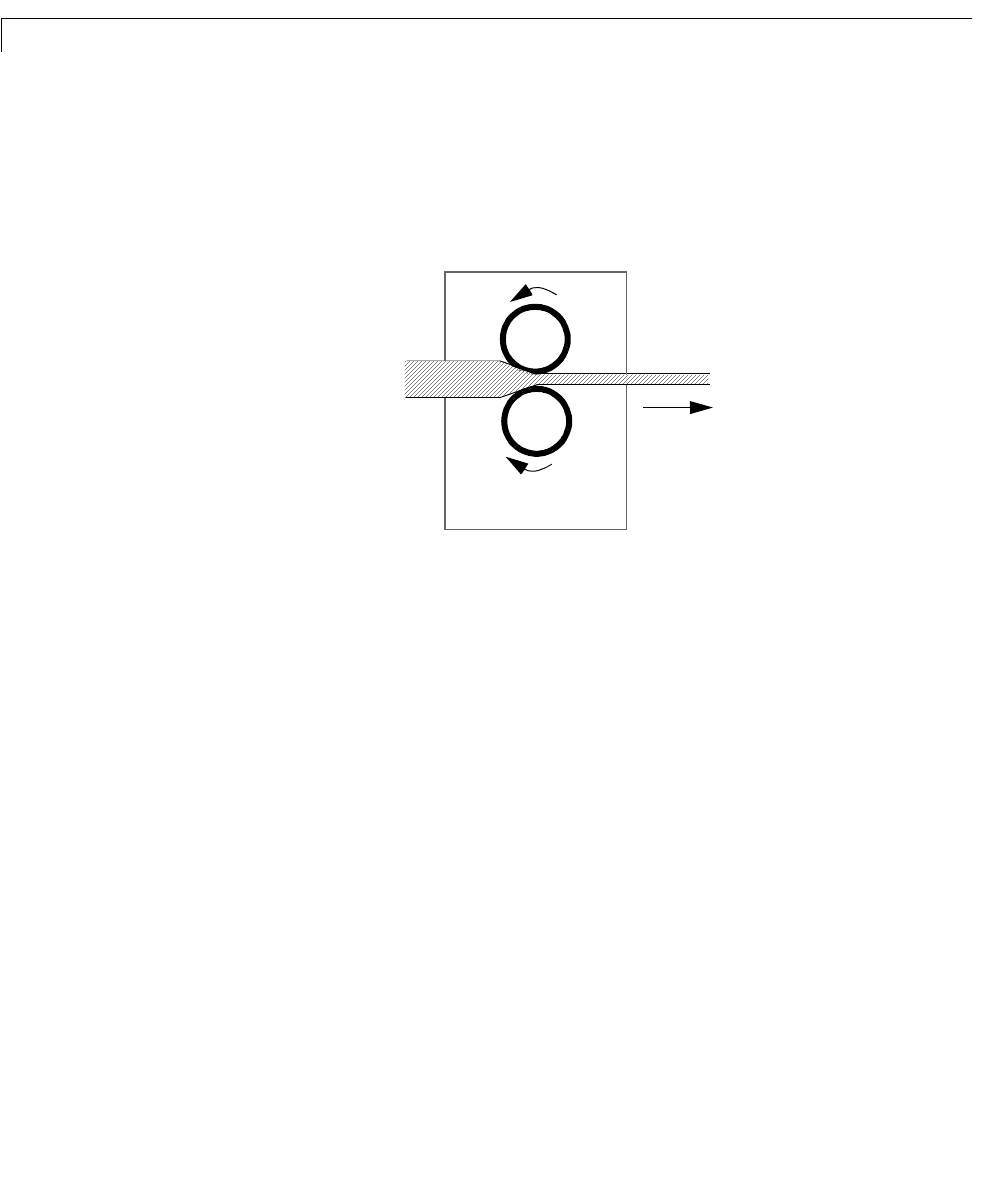

This shape is impressed by two pairs of rolling cylinders (one per axis)

positioned by hydraulic actuators. The gap between the two cylinders is called

the roll gap.

The objective is to maintain the beam thickness along the x- and y-axes within

the quality assurancetolerances. Variations in output thickness can arise from

the following:

•Variations in the thickness/hardness of the incoming beam

•Eccentricity in the rolling cylinders

Feedback control is necessary to reduce the effect of these disturbances.

Because the roll gap cannot be measured close to the mill stand, the rolling

force is used instead for feedback.

The input thickness disturbance is modeled as a low pass filter driven by white

noise. The eccentricity disturbance is approximately periodic and its frequency

is a function of the rolling speed. A reasonable model for this disturbance is a

second-order bandpass filter driven by white noise.

-axis

incoming beam

shaped beam

rolling cylinders

rolling mill stand

x