Instruction Manual

Table Of Contents

- 1 GENERAL INFORMATION

- 2 SAFETY INSTRUCTIONS

- 3 INSTALLATION

- 3.1 Location

- 3.2 Connections

- 3.3 Wiring

- 3.4 Battery capacity

- 3.5 Battery isolator

- 3.6 Connection of second battery (3A output)

- 3.7 Temperature sensor

- 3.8 Voltage sense

- 3.9 Alarm function

- 3.10 RJ12 splitter for enclosure C2

- 3.11 Overview connection compartment

- 3.12 Materials

- 3.13 Connection

- 3.14 Installation step-by-step

- 3.15 Commissioning after installation

- 3.16 Decommissioning

- 3.17 Storage and transportation

- 4 DIP SWITCH SETTINGS

- 5 OPERATION

- 6 MASTERBUS

- 7 TROUBLE SHOOTING

- 8 TECHNICAL DATA

Mass 24/50, 24/75, 24/100, 48/25, 48/50 – User and Installation Manual

13

4 DIP SWITCH SETTINGS

The Mass Charger settings can be adjusted in two ways:

• By means of DIP switches;

• Via the MasterBus network (by means of a remote

control panel or an interface connected to a PC with

MasterAdjust software); see section 6.3 on page 15.

Note: Once a DIP switch has been set to On, MasterBus

presets are disabled but people can still change the

settings!

CAUTION!

Invalid settings of the Mass Charger can cause

serious damage to your batteries and/or the

connected load! Adjustments of settings may be

undertaken by qualified personnel only!

4.1 DIP switch operation

The Mass Charger has six DIP switches. These switches

are operated by flipping the levers to the other position,

using a small screwdriver.

Figure 5. DIP switches

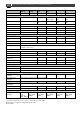

4.2 DIP switch functions

See the table for the functional overview of the DIP

switches (DIP switch 6 is reserved for future use).

Force Float (DIP switch 1)

For special applications a fixed charge voltage can be

required. The battery charger allows you to change the 3-

step+ charge program to a single stage program by

activating the function "Force Float", switching DIP switch

1 to "ON".

The charge voltage will be fixed at 26.5V (24V charger) or

53V for a 48V charger.

Traction setting (DIP switch 2)

Setting for traction charging: +0.7/1.4V during bulk and

+0.4/0.8V in absorption for 24/48V batteries.

Gel/AGM batteries (DIP switch 3)

Some Gel/AGM batteries need a higher float voltage for

optimal charge. Changing the float voltage can be done by

setting DIP switch 3 to "ON". The float voltage will

increase to 27.6V (24V charger) or 55.2V for a 48V

charger.

Diode setting (DIP switch 4)

Setting for +0.6V voltage compensation in case a battery

isolator is used.

DIP SWITCH

5

4

3

2

1

Standard

0

0

0

0

0

Diode

0

1

0

0

0

Gel/AGM

0

0

1

0

0

Diode + Gel/AGM

0

1

1

0

0

Traction

0

0

0

1

0

Traction + Diode

0

1

0

1

0

ContMon + Traction

0

0

1

1

0

ContMon + Traction + Diode

0

1

1

1

0

ForceFloat

0

0

0

0

1

ForceFloat + Diode

0

1

0

0

1

ForceFloat + Gel/AGM

0

0

1

0

1

ForceFloat + Diode + Gel/AGM

0

1

1

0

1

ContMon

0

0

0

1

1

ContMon + Diode

0

1

0

1

1

ContMon + Gel

0

0

1

1

1

ContMon + Diode + Gel/AGM

0

1

1

1

1

Lithium-ion (Mastervolt MLI)

1

0

0

0

0

Lithium-ion + Diode

1

1

0

0

0

Lithium-ion + ForceFloat

1

0

0

0

1

Lithium-ion + ContMon

1

0

0

1

1

1 = On; 0 = Off

ContMon:

Continuous monitor mode. MasterBus,

RS232 and DC alarm stay functioning at

mains failure. Remote stays functioning if it

has its own power source.

Diode:

Diode compensation on (+0.6V)

Gel/AGM:

Gel/AGM compensation on (during float

+1.1V or 2.2V)

Traction

Traction charging (+0.7 or 1.4V during bulk

and +0.4 or 0.8V in absorption).

Force float:

One step charge program with fixed float

voltage.