User Guide

II. Set-up

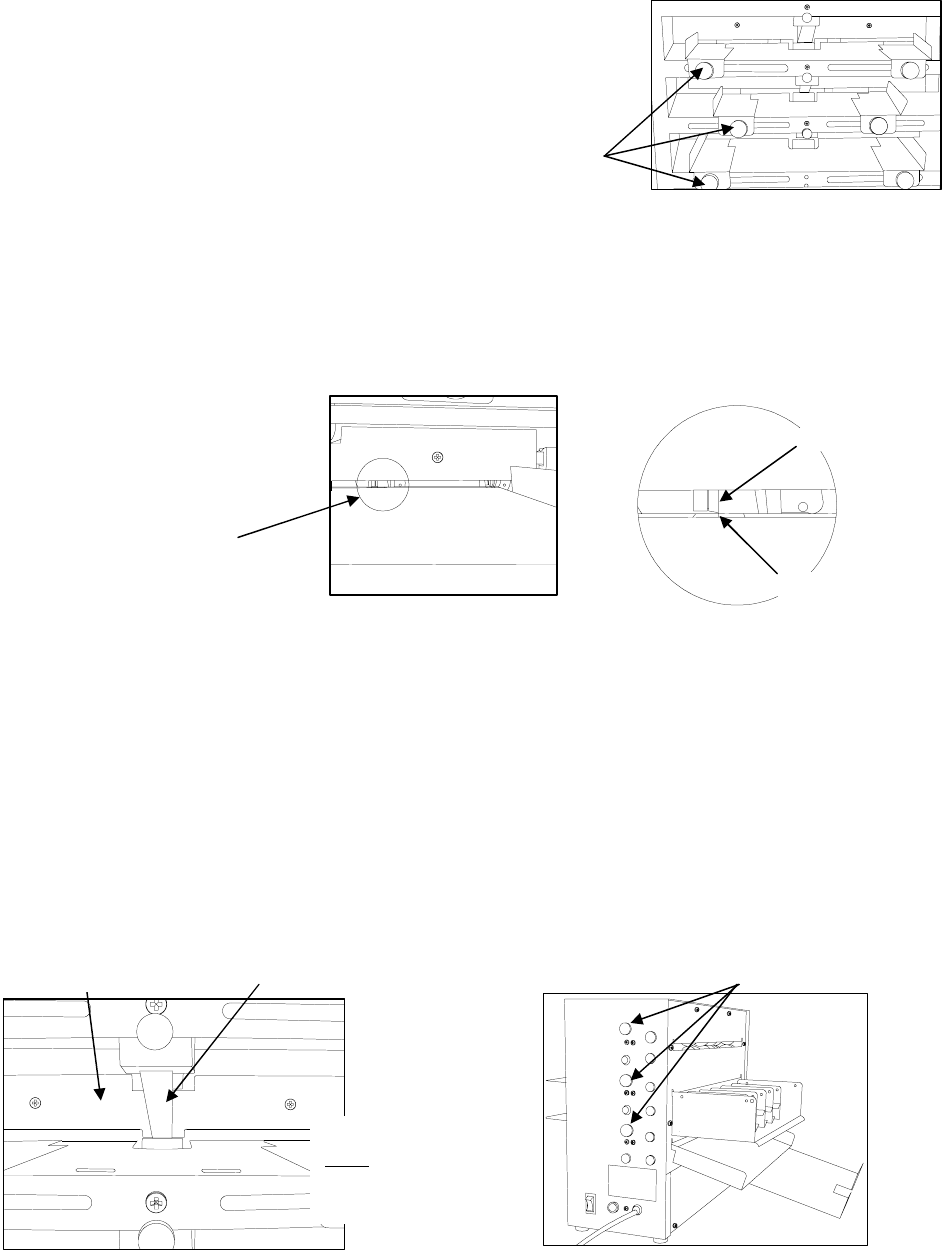

A. Paper guide set up. Not all paper widths are necessarily equal from ream to ream and paper guide

adjustment may be needed for each size. To adjust paper guides, follow the steps below:

1. Turn slitter off and unplug.

2. Slide a single sheet of stock into the appropriate feed shelf.

First pass (3 ½” cut) goes on lower shelf; second pass (2”

cut) goes on the shelf above. Registration marks on stock

must be face up.

3. Push stock all the way in to the blades.

4. Check location of registration marks to

blades. If they do not align, loosen both

and move the paper guides with stock left

or right until the registration marks (see Figure #6) align

themselves with the cutter blades. You may need a flashlight to

see the cutter blades from the feed side. Tighten paper guides down so that side-to-side

movement of stock is no more than 1/64”. Paper guides too tight will result in inconsistent

feeding; too loose will result in skewing.

B. Retarder set-up. See Figure #7 for picture of retarder

location. Retarder is raised or lowered by turning the

retarder adjustment knob as shown in Figure #8. Proceed as listed below.

1. Turn off and unplug machine.

2. Turn all retarder adjustment knobs 1 turn counter clockwise; you should see the paper retarder

rise slightly. Do not turn retarder knob more than 1 turn counter-clockwise.

3. Place a piece of stock between retarder and feed wheel. Slowly turn the appropriate retarder

adjustment knob clockwise until a distinct drag is felt on the feed tire while the stock is moved

in and out. Fine tuning of the retarder can be accomplished by slightly turning the retarder

knob while the slitter is running with stock in it. Note: Retarder should not touch feed

roller.

Figure #7 Figure #8

Align Registration Marks

with Blades (See Inset)

Registration Marks

(on Layout Sheets)

Blade

Paper Guide

Thumb Knobs

Figure #5

Figure #6

Retarder should

never

contact the

feed wheel at this

point

Retarde

r

Pressure Ar

m

Retarder ad

j

ustment knobs