Instruction Manual

Freeze-dryer EPSILON 1-4 LSCplus

Freeze-dryer EPSILON 2-4 LSCplus

7 Malfunctions and error correction

Version 04/2014, Rev. 1.4 of 09/12/2014 • sb

87

Translation of the original operating manual

Pos: 168 /20 0 Chri st/3 60 GT-B A L abor-P ilot (STAN DAR DMODU LE )/0 70 Stö rungen und Fe hlers uche 070 -00 10-002 0 Kein aus reich end es Vaku um @ 25\mo d_1 404 9840600 39_ 68.d ocx @ 184 167 @ 3 @ 1

7.1.2 Insufficient vacuum

NOTE

The vacuum checks must be carried out when the ice condenser is frozen.

Pos: 169 /01 0 Uni v ersal mod ule/L eerz ei le @ 0\m od_ 120 211624 450 0_0. doc x @ 11 4 @ @ 1

Pos: 170 /20 0 Chri st/3 60 GT-BA Labo r-Pi lot (STAND ARD MODU LE)/0 70 Stö run gen und Fe hlers uche 070-00 10- 002 0-0010 K leinfl ans chv erbi ndungen @ 2 5\mod_ 140 4984 061 086_68. docx @ 18 418 1 @ 4 @ 1

7.1.2.1 Small flange connections

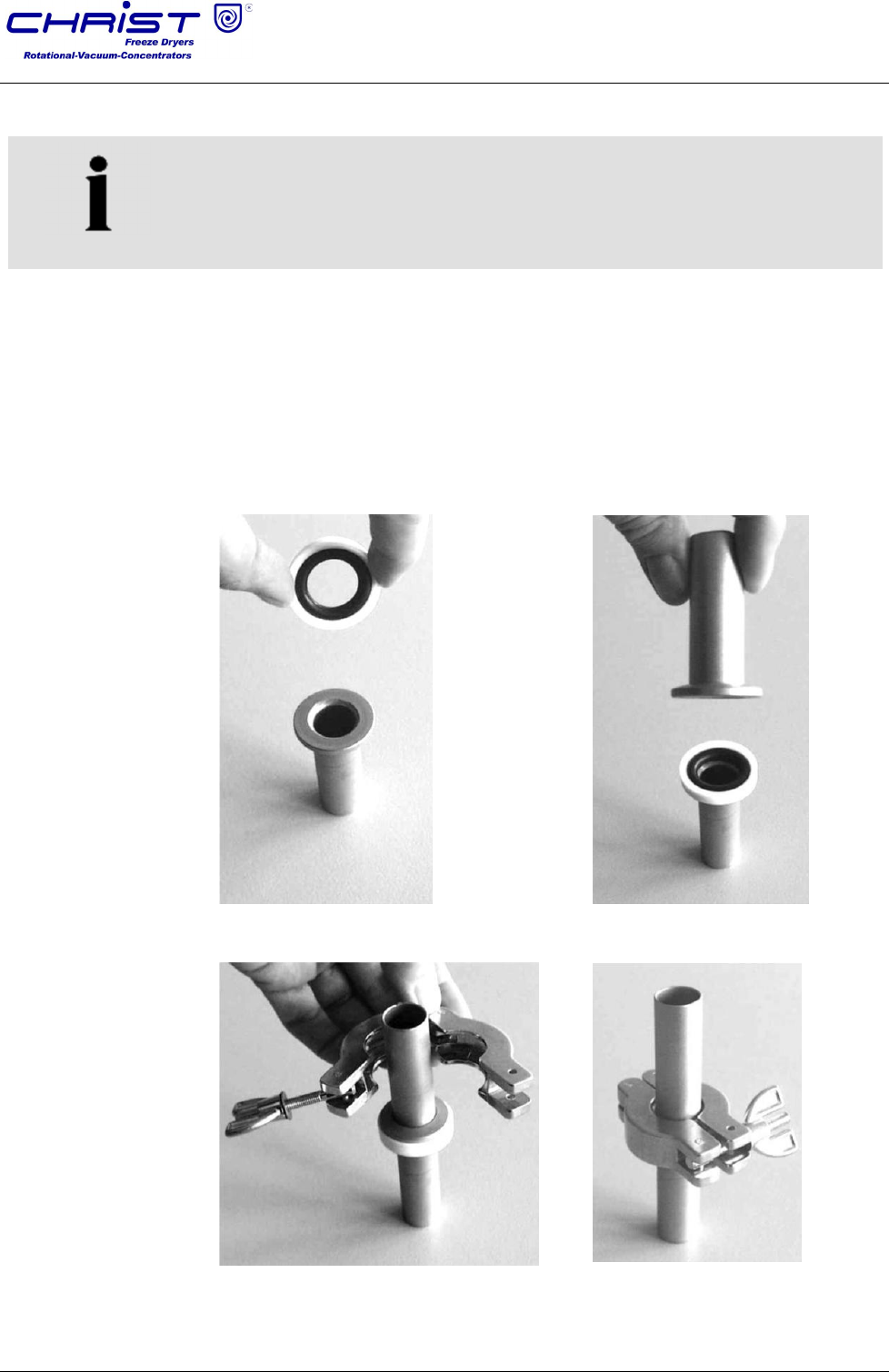

Leakages are often due to improper small flange connections between the

various components and hose connections or to leakages in the valves.

• Loosen the connection and place the centring ring (with sealing ring

inside) in a centred manner between the flange connections.

• Seal the connection with the clamping ring by tightening the wing nut.

• Ensure that the centring ring neither slips out of place nor gets jammed.

Fig. 73: Small flange and centring ring Fig. 74: Small flange with centring ring

and small flange

Fig. 75: Attaching the clamping ring Fig. 76: Tightened clamping ring

Pos: 171 /01 0 Uni v ersal mod ule/L eerz ei le @ 0\m od_ 120 211624 450 0_0. doc x @ 11 4 @ @ 1

Pos: 172 /20 0 Ch ris t/3 61 GT-B A L abo r-Pil ot (PROJ EK TE)/Eps ilo n 2 -4 LSC pl us Sta nda rd/0 70 Stö run gen un d Fehl e rsuch e/07 0-0 010-00 20- 002 0 Bel üft ungs ve ntil (n ur E2 -4) @ 2 5\m od_ 1404984 751 036 _68. docx @ 18 609 9 @ 4 @ 1