Manual

Freeze-dryer EPSILON 2-10D LSCplus

5 Set-up and connection

Version 04/2013, Rev. 1.5 of 16/12/2014 • sb

35

Translation of the original operating manual

Pos: 100 /20 0 Ch rist/3 61 G T-BA L abo r-Pi lot (PROJE KTE )/Epsi lo n Sta nda rd/0 50 Aufs tell ung u nd Ans c hluss/0 50- 003 0 Tro ckne rpat rone (A ds orpti onsfil ter ) - Ü bersc hrift -- ----- ------ -- ----- ----- --- - @ 26\m od_ 140 505 799428 5_68 .docx @ 1 909 60 @ 2 @ 1

5.3 Drying cartridge (adsorption filter)

Pos: 101 /20 0 Ch rist/3 61 G T-BA L abo r-Pilot (PR OJEK TE)/Eps ilo n Sta nda rd/0 50 Aufs tell ung u nd Ansc hl uss/0 50- 0031 Trockne rpat ron e Epsil o n (Vent il + Falt enb alg) - Text @ 25\ mod _14049 846 246 44_6 8.d ocx @ 185 679 @ @ 1

The drying cartridge prevents the air humidity from being absorbed by the

heat transfer medium.

During the transport of the freeze-dryer, the drying cartridge at the filler

neck of the heat transfer medium is removed from the filler neck of the heat

transfer medium. Prior to commissioning the unit, it must be installed.

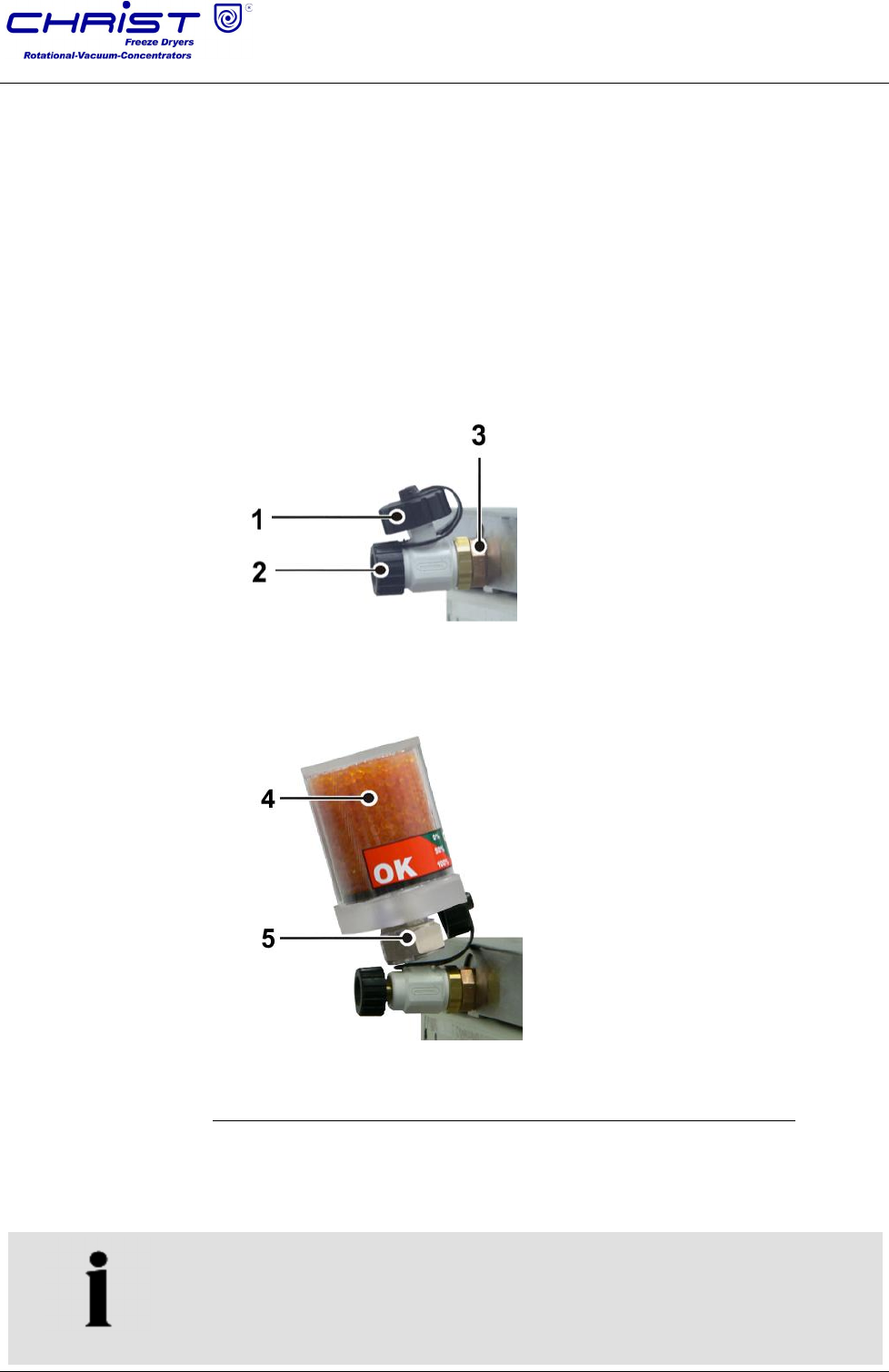

• Remove the sealing cap (1) from the valve.

• Connect the supplied adapter (5) together with the drying cartridge (4)

to the valve (2).

• Open the valve (2) by turning it anti-clockwise up to the stop.

1 Sealing cap

2 Valve

3 Connection of the

expansion vessel

(inside the unit)

Fig. 16: Valve with sealing cap for transport

4 Drying cartridge

(adsorption filter)

5 Adapter

Fig. 17: Valve with drying cartridge (adsorption filter)

Special equipment: Stainless steel bellow at the hydraulic cylinder

If the freeze-dryer is equipped with a stainless steel bellow, a second drying

cartridge is located under the drying chamber (see chapter 2.1.1 - ""). This

drying cartridge is not removed during the transport.

NOTE

The silica gel of the drying cartridges has a limited adsorption capacity.

If the colour of the silica gel changes from orange to green (see label on

the drying cartridge), the drying cartridge must be replaced (Christ order

no. 610 990).