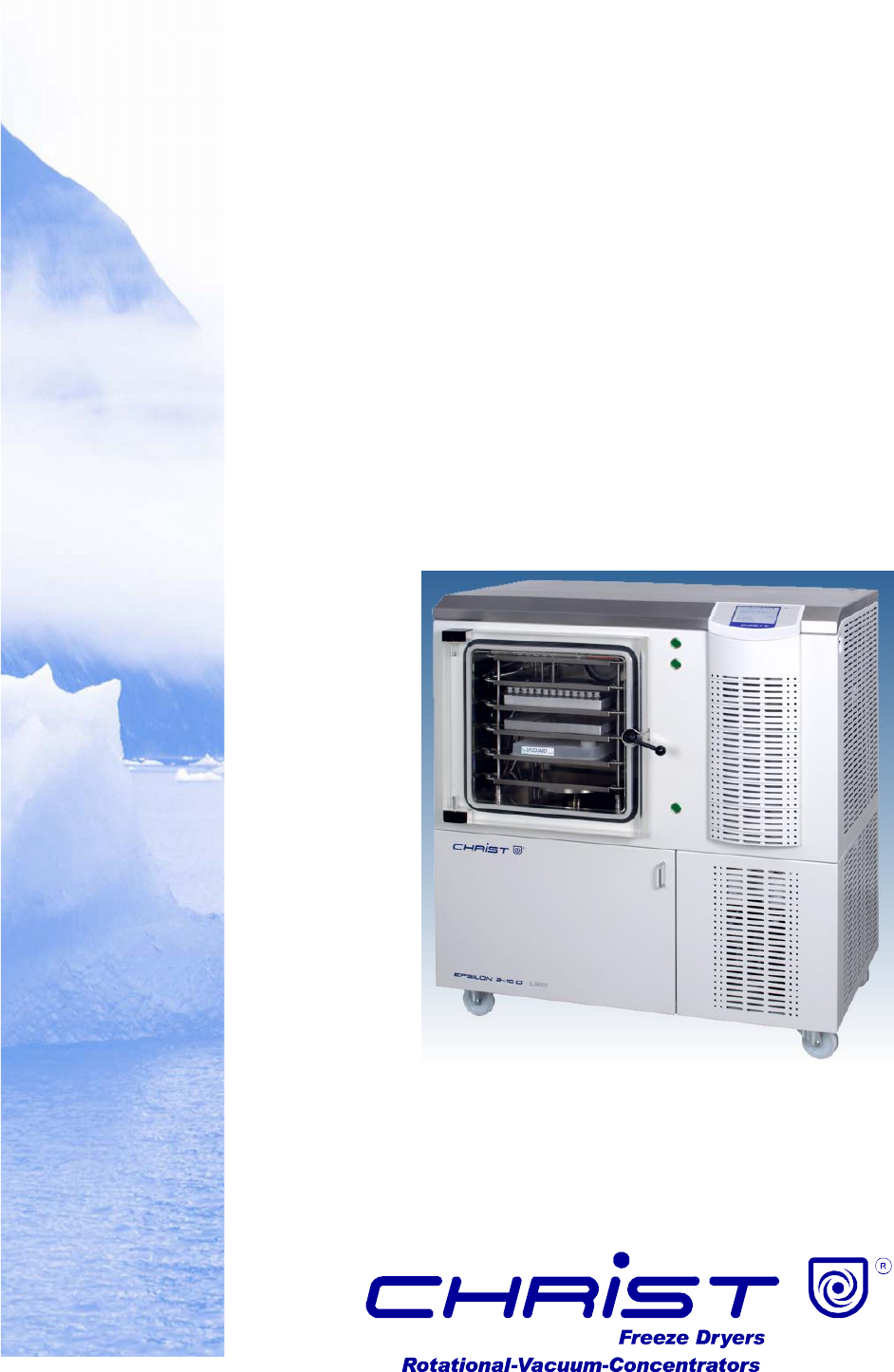

Operating Manual Freeze-dryer EPSILON 2-10D LSCplus Part no. 110825, 110827 Translation of the original operating manual sb Version 04/2013 Rev. 1.

Freeze-dryer EPSILON 2-10D LSCplus 2 Version 04/2013, Rev. 1.

Freeze-dryer EPSILON 2-10D LSCplus In case of inquiries, please state the following numbers: Order number Serial number © Copyright by Martin Christ Gefriertrocknungsanlagen GmbH An der Unteren Söse 50 37520 Osterode am Harz Germany Tel.: +49 (0) 5522 / 5007-0 Fax: +49 (0) 5522 / 5007-12 Web: www.martinchrist.de E-mail: info@martinchrist.de Version 04/2013, Rev. 1.

Freeze-dryer EPSILON 2-10D LSCplus Table of contents 1 General information ............................................................................................................. 9 1.1 Importance of the operating manual.................................................................................. 9 1.2 Intended use ..................................................................................................................... 9 1.3 Warranty and liability................................

Freeze-dryer EPSILON 2-10D LSCplus Table of contents 4 Storage and transport ....................................................................................................... 31 4.1 Dimensions and weight ................................................................................................... 31 4.2 Storage conditions .......................................................................................................... 31 4.3 Notes on transport ....................................

Freeze-dryer EPSILON 2-10D LSCplus Table of contents 6.6 Optional extensions and special equipment .................................................................... 85 6.7 Switching the freeze-dryer OFF ...................................................................................... 87 7 Malfunctions and error correction .................................................................................... 88 7.1 General malfunctions .............................................................

Freeze-dryer EPSILON 2-10D LSCplus Table of contents 8 Version 04/2013, Rev. 1.

Freeze-dryer EPSILON 2-10D LSCplus 1 General information Pos: 1 /2 00 C hrist/ 360 GT -BA Lab or-Pilot (STANDARDM ODULE)/ 010 Allg emei ne I nfor mati one n/01 0 Allge mein e In for matio nen == == === == == === == == == === == == === == @ 24 \mo d_1 404 983 207 982_ 68. docx @ 18 2921 @ 1 @ 1 1 General information Pos: 2 /2 00 C hrist/ 360 GT -BA Lab or-Pilot (STANDARDM ODULE)/ 010 Allg emei ne I nfor mati one n/01 0-0 010 Stelle nwert de r Betri ebsa nleitu ng @ 25\ mod _14 049 832 092 48_6 8.

Freeze-dryer EPSILON 2-10D LSCplus 1 General information Pos: 6 /2 00 C hrist/ 360 GT -BA Lab or-Pilot (STANDARDM ODULE)/ 010 Allg emei ne I nfor mati one n/01 0-0 030 Gew ährl eistun g u nd Ha ftun g @ 2 5\m od_ 140 498 321 137 7_68 .docx @ 1 829 63 @ 2 @ 1 1.3 Warranty and liability The warranty and liability are subject to our "General Terms and Conditions" that were distributed to the operator upon the conclusion of the contract.

Freeze-dryer EPSILON 2-10D LSCplus 1 General information Pos: 14 / 200 Christ /36 1 GT -BA La bor -Pilot (PROJEKTE )/Epsilon 2- 10D LSC plus Sta nda rd/0 10 Allge mei ne In for mati onen /01 0-0 070 Lief eru mfa ng E2 -10D @ 25 \mo d_1 404 984 863 819_ 68. docx @ 18 633 7 @ 2 @ 1 1.

Freeze-dryer EPSILON 2-10D LSCplus 2 Layout and mode of operation Pos: 17 / 200 Christ /36 0 GT -BA La bor -Pilot (S TANDARDMODULE) /02 0 Aufb au u nd Wirk ungs weise/ 020 Aufb au u nd Wir kung sweise == === == == === == == === == == === = @ 25\ mod _14 049 832 3599 4_6 8.

Freeze-dryer EPSILON 2-10D LSCplus 2 Layout and mode of operation 11 Option: Precision control needle valve for air injection 12 Exhaust filter 13 Pressure control valve 14 Vacuum pump Fig. 3: Detailed view B - vacuum pump 15 Mains power switch 16 Switch cabinet (behind the side panel) 17 Sight glass of the heat transfer medium 18 Steerable castors Fig. 4: Right side of the freezedryer Version 04/2013, Rev. 1.

Freeze-dryer EPSILON 2-10D LSCplus 2 Layout and mode of operation 19 Vacuum sensor (behind the side panel) 20 Sight glass of the ice condenser 21 Aeration valve 22 Access flange DN40 (e.g. for weighing device, behind the side panel) 23 Media drain valve of the ice condenser chamber 24 Special equipment: Drain valve of the bellows of the hydraulic system 25 Fixed castors Fig.

Freeze-dryer EPSILON 2-10D LSCplus 2 Layout and mode of operation Water-cooled freeze-dryer: 36 Media connector block Fig. 7: Rear view of a watercooled freeze-dryer 37 Connector for the cooling water intlet 38 Connector for the cooling water outlet 39 Media drain valve of the ice condenser chamber (alternatively to item 23) Fig. 8: Detailed view C media connector block Pos: 20 / 010 Unive rsalm odul e/Seite nwechs el @ 0 \mo d_1 202 116 244 312_ 0.d ocx @ 105 @ @ 1 Version 04/2013, Rev. 1.

Freeze-dryer EPSILON 2-10D LSCplus 2 Layout and mode of operation Pos: 21 / 200 Christ /36 1 GT -BA La bor -Pilot (PROJEKTE )/Epsilon 2- 10D LSC plus Sta nda rd/0 20 Auf bau un d Wirku ngsweis e/02 0- 0010 -00 20 Ty pensc hild E2- 10D @ 25\ mo d_14 049 848 817 27_ 68.d ocx @ 186 365 @ 3 @ 1 2.1.

Freeze-dryer EPSILON 2-10D LSCplus 2 Layout and mode of operation Pos: 23 / 200 Christ /36 0 GT -BA La bor -Pilot (S TANDARDMODULE) /02 0 Aufb au u nd Wirk ungs weise/ 020 -00 20 Wi rkun gsweise -- --- --- -- --- -- --- -- --- - @ 25\m od_ 140 498 325 385 0_6 8.docx @ 1 830 47 @ 2 @ 1 2.2 Mode of operation Pos: 24 / 200 Christ /36 0 GT -BA La bor -Pilot (S TANDARDMODULE) /02 0 Aufb au u nd Wirk ungs weise/ 020 -00 20- 001 0 G efrie rtr ocknu ng allgem ein @ 25\ mod _14 049 832 548 15_ 68.

Freeze-dryer EPSILON 2-10D LSCplus 2 Layout and mode of operation Melting point pressure curve Pressure (mbar) SOLID A Melting B Sublimation 0.37 mbar V Su apo bl ur im p at res io s n ur pr e es cu su rv re e f cu or rv ice e = 6.11 mbar LIQUID ou Vap r ssu pre e urv re c Evaporation Triple point GASEOUS -30°C Temperature (°C) Fig.

Freeze-dryer EPSILON 2-10D LSCplus 2 Layout and mode of operation Pressure (mbar) 1 bar LIQUID Melting point pressure curve 1 SOLID cur ve Triple point Va p su ou bl r p im re at ss io ur n e pr cu es rv su e re for cu ic rv e = e 2 ou Vap ur e ess r pr GASEOUS 20°C Temperature (°C) Fig. 11: Freeze-drying phases Please find further information about basic principles, optimum procedures and applications in the brochure "Smart freeze-drying", which can be downloaded at www.martinchrist.

Freeze-dryer EPSILON 2-10D LSCplus 2 Layout and mode of operation Pos: 26 / 200 Christ /36 0 GT -BA La bor -Pilot (S TANDARDMODULE) /02 0 Aufb au u nd Wirk ungs weise/ 020 -00 20- 002 0 Abla uf ei nes G efrie rtr ockn ungs proz esses @ 25 \mo d_1 404 983 2559 39_ 68. docx @ 18 3075 @ 3 @ 1 2.2.

Freeze-dryer EPSILON 2-10D LSCplus 2 Layout and mode of operation Fig. 12: Shell freezing Fig. 13: Cooling bath with spin freezing device NOTE Fig. 14: Spin freezing If the product that is to be dried contains solvents or high salt concentrations, it may start to thaw during the drying process, which is indicated by clearly visible foaming. In order to prevent this, the product must be frozen as deeply as possible, e.g. with the aid of liquid nitrogen, prior to putting it into the unit.

Freeze-dryer EPSILON 2-10D LSCplus 2 Layout and mode of operation The end of the main drying phase is reached, when the product temperature and the shelf temperature are nearly identical. The temperature difference between the shelf and the product should be approximately 3 K to 5 K. Pos: 33 / 010 Unive rsalm odul e/Le erzeil e @ 0\mo d_1 202 116 244 500 _0.

Freeze-dryer EPSILON 2-10D LSCplus 3 Safety Pos: 41 / 200 Christ /36 0 GT -BA La bor -Pilot (S TANDARDMODULE) /03 0 Sicher heit/ 030 Siche rheit == === == == === == == == === == == === == == === @ 2 5\m od_ 1404 983 296 098 _68. docx @ 18 320 1 @ 1 @ 1 3 Safety Pos: 42 / 200 Christ /36 0 GT -BA La bor -Pilot (S TANDARDMODULE) /03 0 Sicher heit/ 030 -00 10 B eschilde ru ng d es Ge räts @ 2 5\mo d_1 404 983 297 040 _68. docx @ 18 321 5 @ 2 @ 1 3.

Freeze-dryer EPSILON 2-10D LSCplus 3 Safety Pos: 44 / 200 Christ /36 0 GT -BA La bor -Pilot (S TANDARDMODULE) /03 0 Sicher heit/ 030 -00 20 Sy mbol - un d Hinw eiserkl äru nge n @ 2 5\m od_ 140 498 3298 133 _68 .docx @ 1 8322 9 @ 2 @ 1 3.2 Explanation of the symbols and notes This operating manual uses the following names and symbols to indicate hazards: This symbol stands for a direct hazard to the life and health of persons.

Freeze-dryer EPSILON 2-10D LSCplus 3 Safety Pos: 46 / 200 Christ /36 0 GT -BA La bor -Pilot (S TANDARDMODULE) /03 0 Sicher heit/ 030 -00 30 V era ntwor tun g des Betr eiber s @ 2 5\m od_ 140 498 3299 227 _68 .docx @ 1 8324 3 @ 2 @ 1 3.3 Responsibility of the operator The operator is responsible to authorise only qualified personnel to work on the freeze-dryer (see chapter 3.4 - "Operating personnel").

Freeze-dryer EPSILON 2-10D LSCplus 3 Safety Pos: 52 / 200 Christ /36 0 GT -BA La bor -Pilot (S TANDARDMODULE) /03 0 Sicher heit/ 030 -00 60 Sic her heitshi nweise ++ +++ ++ ++ +++ ++ ++ +++ ++ ++ ++ +++ + @ 25\ mod _14 0498 330 236 1_6 8.do cx @ 1 832 85 @ 2 @ 1 3.6 Safety instructions The following instructions must be observed prior to every drying process: • • WARNING • • • • • Ensure that the freeze-dryer was set up and connected properly (see chapter 5 - "Set-up and connection").

Freeze-dryer EPSILON 2-10D LSCplus 3 Safety Pos: 57 / 200 Christ /36 0 GT -BA La bor -Pilot (S TANDARDMODULE) /03 0 Sicher heit/ 030 -00 60- 002 0 Mech anisch e Siche rheit @ 25 \mo d_1 404 983 304 593 _68. docx @ 18 331 3 @ 3 @ 1 3.6.2 Mechanical safety In order to ensure the safe operation of the freeze-dryer, please comply with the following points: • • • WARNING • • • • • • • Do not use the freeze-dryer if it was installed incorrectly. Do not use the freeze-dryer without panels.

Freeze-dryer EPSILON 2-10D LSCplus 3 Safety Pos: 62 / 200 Christ /36 0 GT -BA La bor -Pilot (S TANDARDMODULE) /03 0 Sicher heit/ 030 -00 60- 003 0 Br andsc hutz @ 25 \mo d_1 404 983 3057 08_ 68. docx @ 18 3327 @ 3 @ 1 3.6.3 Fire prevention Fuses protect certain electrical circuits within the freeze-dryer against overcurrent conditions. • • • DANGER Always use fuses of the same type and rating. Do not dry explosive or inflammable substances.

Freeze-dryer EPSILON 2-10D LSCplus 3 Safety Pos: 70 / 200 Christ /36 0 GT -BA La bor -Pilot (S TANDARDMODULE) /03 0 Sicher heit/ 030 -00 70 Sic her heitsei nricht ung en- -- --- -- --- --- -- --- -- --- -- --- --- -- --- -- --- --- -- --- -- -- @ 25\ mod _14 049 833 091 10_6 8.d ocx @ 183 369 @ 2 @ 1 3.7 Safety devices Pos: 71 / 200 Christ /36 0 GT -BA La bor -Pilot (S TANDARDMODULE) /03 0 Sicher heit/ 030 -00 70- 001 0 Syst emko ntr olle LSCpl us @ 2 5\m od_ 140 498 331 0307 _68 .

Freeze-dryer EPSILON 2-10D LSCplus 3 Safety Pos: 75 / 200 Christ /36 0 GT -BA La bor -Pilot (S TANDARDMODULE) /03 0 Sicher heit/ 030 -00 90 R estrisik en @ 25\ mod _14 049 833 155 77_ 68.d ocx @ 183 453 @ 2 @ 1 3.9 Remaining hazards All CHRIST freeze-dryers were built state-of-the-art and according to the accepted safety rules.

Freeze-dryer EPSILON 2-10D LSCplus 4 Storage and transport Pos: 78 / 200 Christ /36 0 GT -BA La bor -Pilot (S TANDARDMODULE) /04 0 La ger ung und Tr ans port /040 L age run g un d T rans por t= === == == === == == === == == === == @ 2 5\mo d_1 404 983 713 664 _68.

Freeze-dryer EPSILON 2-10D LSCplus 4 Storage and transport Pos: 85 / 200 Christ /36 1 GT -BA La bor -Pilot (PROJEKTE )/Epsilon 2- 10D LSC plus Sta nda rd/0 40 Lage ru ng u nd Tra nspo rt/0 40- 004 0 Ve rpack ung E2-1 0D @ 25\m od_ 140 498 489 431 9_68 .docx @ 1 864 07 @ 2 @ 1 4.4 Packaging The freeze-dryer is packaged in a wooden crate. • After opening the packaging, take out the accessories. • Remove the packaging material. • Remove the side walls of the crate.

Freeze-dryer EPSILON 2-10D LSCplus 4 Storage and transport Pos: 89 / 200 Christ /36 1 GT -BA La bor -Pilot (PROJEKTE )/Epsilon 2- 10D LSC plus Sta nda rd/0 40 Lage ru ng u nd Tra nspo rt/0 40- 006 0 I nne rbet rieblic her Tr ansp ort E 2-1 0D @ 2 5\m od_ 140 498 489 5389 _68 .docx @ 1 864 21 @ 2 @ 1 4.6 On-site transport The freeze-dryer comes with castors. It can be pushed by a suitable number of persons over short distances.

Freeze-dryer EPSILON 2-10D LSCplus 5 Set-up and connection Pos: 92 / 200 Christ /36 0 GT -BA La bor -Pilot (S TANDARDMODULE) /05 0 Aufstell ung und Anschlus s/05 0 Aufs tellun g u nd Ansc hluss= == == === == == === == == == === == @ 25 \mo d_1 404 983 7372 44_ 68. docx @ 18 3495 @ 1 @ 1 5 Set-up and connection Pos: 93 / 200 Christ /36 0 GT -BA La bor -Pilot (S TANDARDMODULE) /05 0 Aufstell ung und Anschlus s/05 0-0 011 Aufst ellort (Epsilon ) @ 25\ mod _14 049 8373 912 9_6 8.d ocx @ 1835 23 @ 2 @ 1 5.

Freeze-dryer EPSILON 2-10D LSCplus 5 Set-up and connection Pos: 100 /20 0 Ch rist/3 61 G T-BA L abo r-Pilot (PROJEKTE)/Epsilo n Sta nda rd/0 50 Aufs tellun g u nd Ansc hluss/0 50- 003 0 Tro ckne rpat ron e (Ad sor ptionsfilt er ) - Ü bersc hrift -- --- -- --- --- -- --- -- --- -- --- - @ 26\m od_ 140 505 799 428 5_68 .docx @ 1 909 60 @ 2 @ 1 5.

Freeze-dryer EPSILON 2-10D LSCplus 5 Set-up and connection Pos: 102 /01 0 Univ ersal mod ule/Seit enwec hsel @ 0\m od_ 120 211 624 4312 _0. docx @ 10 5 @ @ 1 Pos: 103 /20 0 Ch rist/3 61 G T-BA L abo r-Pilot (PROJEKTE)/Epsilo n Sta nda rd/0 50 Aufs tellun g u nd Ansc hluss/0 50- 004 0 Vak uu mmess sond e - Übe rschrif t-- -- --- -- --- --- -- --- -- --- --- -- --- @ 2 6\m od_ 1405 058 078 325 _68. docx @ 19 098 7 @ 2 @ 1 5.

Freeze-dryer EPSILON 2-10D LSCplus 5 Set-up and connection Thyracont VSP62/63 MKS 722B Pfeiffer TPR 280/281 Fig. 19: Installed vacuum sensors of different manufacturers The vacuum sensor comes supplied in a calibrated state. NOTE After power-on, the vacuum sensor needs a few minutes to reach its operating temperature. Pos: 105 /01 0 Univ ersal mod ule/Seit enwec hsel @ 0\m od_ 120 211 624 4312 _0. docx @ 10 5 @ @ 1 Version 04/2013, Rev. 1.

Freeze-dryer EPSILON 2-10D LSCplus 5 Set-up and connection Pos: 106 /20 0 Ch rist/3 61 G T-BA L abo r-Pilot (PROJEKTE)/Epsilo n Sta nda rd/0 50 Aufs tellun g u nd Ansc hluss/0 50- 005 0 Be dien ung der B elade tür E psilon - Übe rsch rift- -- --- --- -- --- -- --- -- --- --- -- --- -- --- - @ 25\ mod_ 140 498 462 812 8_6 8.docx @ 1 857 21 @ 2 @ 1 5.

Freeze-dryer EPSILON 2-10D LSCplus 5 Set-up and connection Fig. 21: Shelf movement push-buttons at the operating panel (example illustration) In order to move the shelves, the respective push-button has to be kept pressed in combination with "Release". The shelves will move continuously until one of the buttons is released or the upper or lower hard stop position has been reached.

Freeze-dryer EPSILON 2-10D LSCplus 5 Set-up and connection Pos: 116 /20 0 Ch rist/3 61 G T-BA L abo r-Pilot (PROJEKTE)/Epsilo n Sta nda rd/0 50 Aufs tellun g u nd Ansc hluss/0 50- 006 0 Belü ftun gsven til Epsilon @ 25 \mo d_1 404 984 632 770_ 68. docx @ 18 577 7 @ 2 @ 1 5.8 Aeration valve The aeration valve is located on top of the left side of the unit (see chapter 2.1.1 - ""). After the end of a freeze-drying process, the unit will be aerated via the aeration valve.

Freeze-dryer EPSILON 2-10D LSCplus 5 Set-up and connection Pos: 121 /20 0 Ch rist/3 61 G T-BA L abo r-Pilot (PROJEKTE)/Epsilo n Sta nda rd/0 50 Aufs tellun g u nd Ansc hluss/0 50- 007 1 So nde rauss tatt ung: Fei nre gel-N adelv entil Epsilo n @ 25\ mod_ 140 498 463 498 1_6 8.docx @ 1 858 05 @ 2 @ 1 5.10 Special equipment: Precision control needle valve for air injection In addition to the aeration valve, a precision control needle valve is also installed (position chapter 2.1.1 - "").

Freeze-dryer EPSILON 2-10D LSCplus 5 Set-up and connection Pos: 126 /20 0 Ch rist/3 61 G T-BA L abo r-Pilot (PROJEKTE)/Epsilo n Sta nda rd/0 50 Aufs tellun g u nd Ansc hluss/0 50- 009 0 D ruckst eue rven til Epsilon (au ße r 2 -4) @ 25 \mo d_1 404 984 6375 31_ 68. docx @ 18 5833 @ 2 @ 1 5.12 Pressure control valve The pressure control valve is integrated in the suction pipe between the vacuum pump and ice condenser chamber.

Freeze-dryer EPSILON 2-10D LSCplus 6 Operation Pos: 129 /20 0 Ch rist/3 60 G T-BA L abo r-Pilot (STANDARDMODU LE)/0 60 Bet rieb/ 060 B etrie b= === == == === == == === == == === == == == === == == == @ 25\ mod _14 049 837 597 58_6 8.d ocx @ 183 578 @ 1 @ 1 6 Operation Pos: 130 /20 0 Ch rist/3 60 G T-BA L abo r-Pilot (STANDARDMODU LE)/0 60 Bet rieb/ 060 -00 10 E rste I nbe trie bnah me ++ +++ ++ ++ +++ ++ ++ +++ ++ ++ ++ + @ 2 5\m od_ 140 4983 760 674 _68. docx @ 18 359 2 @ 2 @ 1 6.

Freeze-dryer EPSILON 2-10D LSCplus 6 Operation Pos: 138 /20 0 Ch rist/3 60 G T-BA L abo r-Pilot (STANDARDMODU LE)/0 60 Bet rieb/ LSCplus/ 060 -00 50 LSCplus Anl age nsteu eru ng Epsil on - -- --- -- --- --- -- --- -- --- --- -- --- -- --- -- --- --- @ 2 5\m od_ 1404 983 956 815 _68. docx @ 18 369 0 @ 2 @ 1 6.5 LSCplus control system The control system LSCplus (Lyo Screen Control plus) was specifically developed for the control of freeze-drying processes.

Freeze-dryer EPSILON 2-10D LSCplus 6 Operation The user interface is divided into four main windows that can be called up by touching the corresponding buttons: Manual This window is also the standard user interface. It is used to control the freeze-drying process manually. Program This area is used to create and execute programs for automating the freeze-drying process and for making it reproducible. This function is only available in combination with the programmer module PGMplus option.

Freeze-dryer EPSILON 2-10D LSCplus 6 Operation Status line (1) This line shows the operating status of the freeze-dryer as well as the active phase. The status line also shows the current date and time. The clock is batterybuffered and must be reset after a failure (see chapter 6.5.1.3 - "Main window "Options"", section "Administration"). In addition, the drive symbol provides information concerning the status of the external data storage device or of the network drive.

Freeze-dryer EPSILON 2-10D LSCplus 6 Operation Actual values of the current process (4) This area shows the current process data. The fields can be configured as desired: • Select the button of the field that is to be adapted. A dialog box opens: Fig. 26: Dialog box "Select actual value" • Select the desired configuration or quit the dialog box by pressing the "return" button. In this way, it is possible to configure a personalised overview of the actual values.

Freeze-dryer EPSILON 2-10D LSCplus 6 Operation Option: USB process recording (see chapter 6.6 - "Optional extensions and special equipment") • Select the "Process recording" function in the dialog box "Tools". • Select the input fields ("Batch data"). A keyboard for the data input will be displayed. • If necessary, select the “Options” tab, choose between manual or automatic recording, and define a recording interval. • Press the "return" button in order to close the dialog box.

Freeze-dryer EPSILON 2-10D LSCplus 6 Operation Fig. 29: Dialog box "Pressure increase test" • The "Test stop" button stops the pressure increase test. Option: LyoBalance weighing system If the freeze-dryer is equipped with a LyoBalance weighing system (see chapter 6.6 - "Optional extensions and special equipment"), then the corresponding parameters must be configured in this dialog box.

Freeze-dryer EPSILON 2-10D LSCplus 6 Operation Dialog box "Process and equipment messages" (7) This dialog box shows and saves all of the error messages and other messages. In the event of an error or message, the window “Process and equipment messages” will open automatically. In addition, a sound signal is emitted until the error is acknowledged.

Freeze-dryer EPSILON 2-10D LSCplus 6 Operation Details Touching the message calls up details concerning the error message: • Cause of the message, • Effects of the message, • Measures to eliminate the error, • Reference designator, • Error counter (indicates how often this error has occurred) and the time stamp of the last error message. Use the arrow keys to call up the individual windows. The error message text is always followed by an error code.

Freeze-dryer EPSILON 2-10D LSCplus 6 Operation Dialog box "Operating mode: select/start" (8) After the set values have been entered for the process, the process can be started manually with this function (see chapter 6.5.2 - "Manual freezedrying"). Fig. 34: Dialog box "Operating mode: select/start" (The version of the dialog box that is displayed depends on the equipment of the freeze-dryer.

Freeze-dryer EPSILON 2-10D LSCplus 6 Operation Pos: 144 /20 0 Ch rist/3 60 G T-BA L abo r-Pilot (STANDARDMODU LE)/0 60 Bet rieb/ LSCplus/ 060 -00 50- 001 0-0 021 Hau ptfe nster Prog ra mm Epsil on @ 25\ mod _14 049 839 6583 4_6 8.d ocx @ 183 788 @ 4 @ 1 6.5.1.2 Main window "Program" In the main window "Program", pre-programmed freeze-drying processes can be loaded and edited and new programs can be created with the PGMplus programmer module. 1 2 3 Program list Button "New program" Buttons "Load" Fig.

Freeze-dryer EPSILON 2-10D LSCplus 6 Operation Pos: 146 /20 0 Ch rist/3 60 G T-BA L abo r-Pilot (STANDARDMODU LE)/0 60 Bet rieb/ LSCplus/ 060 -00 50- 001 0-0 031 Hau ptfe nster Opti one n Epsilon - 1 Vakuu mpu mp e @ 2 5\m od_ 140 498 3968 681 _68 .docx @ 1 8381 6 @ 4 @ 1 6.5.1.3 Main window "Options" The main window "Options" is used to perform fundamental basic settings of the control system in order to adapt it perfectly to the respective area of application of the freeze-dryer.

Freeze-dryer EPSILON 2-10D LSCplus 6 Operation Change scale unit (2) This dialog box is used to change the unit of measurement for the temperature and vacuum. Fig. 38: Dialog box "Change scale unit" Special equipment: Preselection of the aeration medium (3) This function can be performed in the manual mode or saved together with a program (see chapter 6.5.3.1 - "Creating a program").

Freeze-dryer EPSILON 2-10D LSCplus 6 Operation The following media preselection settings are possible: • Air: Preselects the media connection "Air". • Inert gas: Preselects the media connection "Inert Gas". • Automatic: Automatic media connection preselection depending on the chamber pressure and stoppering status of the product vials: – Chamber pressure 950 mbar: Preselection of the media connection "Air". – Chamber pressure < 950 mbar: Preselection of the media connection "Inert gas".

Freeze-dryer EPSILON 2-10D LSCplus 6 Operation Special equipment: Inertisation (5) (see chapter 6.6 - "Optional extensions and special equipment") In order to start an inertisation process, all of the aeration ports must be connected to the inert gas supply. The aeration valves are disabled during an active inertisation process.

Freeze-dryer EPSILON 2-10D LSCplus 6 Operation Administration “Administration” options: 1 "Date/Time" 2 "Network" 3 "System properties" 4 "Access protection" 5 "Device options" 6 "Configuration of sensors" 7 "WTMplus configuration" Fig. 42: Dialog box "Options/Administration" Date/Time (1) The LSCplus control system is equipped with an integrated, batterybuffered clock. After a failure of the buffer battery, the date and time must be reset. Fig.

Freeze-dryer EPSILON 2-10D LSCplus 6 Operation Fig. 44: Dialog box "Network" System properties (3) This dialog box is used to change various system settings. Fig. 45: Dialog box "System properties" Beeper: The beeper sounds in the event of a malfunction, for example. • If the setting is "On", the beeper sounds every few seconds until the user acknowledges the message. • If the setting is "Silent", the beeper sounds once when the malfunction occurs.

Freeze-dryer EPSILON 2-10D LSCplus 6 Operation Access protection (4) In this dialog box, the access rights can be managed on several levels and they can be protected with a password. In the factory setting with an activated access protection, data can be viewed but not edited. Fig. 46: Dialog box "Access protection" The other buttons cannot be activated unless the access protection is active.

Freeze-dryer EPSILON 2-10D LSCplus 6 Operation Operator/maintenance/administrator password: For each of these access levels, certain editing rights have been defined.They can be enabled with the corresponding password. The rights of the various access levels are detailed in the following table. Action Operator Maintenance Administrator Editing of the data of the current process run (e.g. selection of the operating mode, changing of set values) Editing of maintenance functions (e.g.

Freeze-dryer EPSILON 2-10D LSCplus 6 Operation Configuration of sensors (6) The sensor configurations depend on the equipment version of the unit. If the configuration is incorrect, the correct operation of the unit cannot be guaranteed. CAUTION This dialog box is used to configure the existing vacuum and pressure sensors. For the vacuum as well as pressure, there are two different measuring methods, and for each of these methods, different sensors can be selected.

Freeze-dryer EPSILON 2-10D LSCplus 6 Operation WTMplus configuration (7) The dialog box is displayed for information purposes only. The configuration can be changed only via the LPCplus user interface. NOTE This dialog box shows all of the existing WTMplus sensors. Every sensor is assigned to a measuring channel based on its serial number. Next to the Number of the measuring channel and the serial number of the sensor, the associated temperature and a signal quality index (SQI) are displayed.

Freeze-dryer EPSILON 2-10D LSCplus 6 Operation Service “Service” options: 1 "Operating hours" 2 "Failure memory" 3 "Vacuum pump oil change" 4 "Maintenance" 5 "Sensor adjustment" Fig. 52: Dialog box "Service" (varies depending on the type of system) Operating hours (1) This dialog box is used to call up the number of operating hours of the various components of the freeze-dryer, e.g. the refrigeration unit, vacuum pump, or pressure control valve.

Freeze-dryer EPSILON 2-10D LSCplus 6 Operation Always indicate the error code in the event of enquiries or service requests! NOTE Fig. 54: Dialog box "Failure memory" Vacuum pump oil change (4) The system monitors the oil change interval of the vacuum pump. The interval can be adapted to the vacuum pump model and utilisation. When the end of an oil change interval is reached, a corresponding message will be displayed. • Acknowledge the message. • Change the oil of the vacuum pump.

Freeze-dryer EPSILON 2-10D LSCplus 6 Operation Maintenance (5) The maintenance interval of the unit is fixed at 3,000 operating hours or at least one maintenance per year. When the end of a maintenance interval is reached, a corresponding message will be displayed. • Acknowledge the message. • Make an appointment for the maintenance of your freeze-dryer. • After the maintenance, our service engineer will reset the operating hour counter in the dialog box "Maintenance". Fig.

Freeze-dryer EPSILON 2-10D LSCplus 6 Operation Sensor adjustment (6) Misadjusted sensors will lead to incorrect measurement values, which in turn will have a negative effect on the process control. CAUTION In this dialog box, the sensors are adjusted in terms of a predefined reference value. • Press the button in order to select the sensor. A selection menu will be displayed. • Enter a reference value and press the button "Adjust". Fig.

Freeze-dryer EPSILON 2-10D LSCplus 6 Operation Pos: 148 /20 0 Ch rist/3 60 G T-BA L abo r-Pilot (STANDARDMODU LE)/0 60 Bet rieb/ LSCplus/ 060 -00 50- 001 0-0 041 Hau ptfe nster "? " Epsilo n @ 25\ mod_ 140 498 397 319 3_6 8.doc x @ 1 838 58 @ 4 @ 1 6.5.1.4 Main window "?" This main window includes the most important information concerning your freeze-dryer: 1 2 3 4 Freeze-dryer type Control system type Serial number Manufacturer contact data 5 Details concerning the software version Fig.

Freeze-dryer EPSILON 2-10D LSCplus 6 Operation In the manual mode, the set values of the active phase can be changed during the process run. In this case, the control system adapts the unit to the new set values as quickly as possible. After the completion of a phase, the system switches to the next phase without switching the unit to standby. The transition from "freezing" to "warm-up" takes place automatically. After the completion of the warm-up phase, this dialog box will be displayed: Fig.

Freeze-dryer EPSILON 2-10D LSCplus 6 Operation 1 2 "Aeration" button "Defrosting" button 3 "Media drain" button (special equipment) "Leakage test" button 4 Fig. 60: Dialog box "Set values: view/edit" Fields that are displayed in the form of buttons can be edited. • Aeration (1) If the freeze-dryer is equipped with an automatic aeration valve, this button is used to define the aeration pressure.

Freeze-dryer EPSILON 2-10D LSCplus 6 Operation • • • Confirm the new value and quit the numerical keypad by pressing the button "Accept". Confirm the input and quit the dialog box via the button "Accept". If the dialog box is closed by the button "return", the changes will be discarded. Pos: 154 /01 0 Univ ersal mod ule/L eerz eile @ 0\m od_ 120 211 624 450 0_0.

Freeze-dryer EPSILON 2-10D LSCplus 6 Operation +40 T/°C Pressure/mbar +30 100 Set value of the previous section +20 10 Course of the shelf temperature control set value +10 1 0.1 0 0.01 -10 Set value of the current section -20 -30 1000 Previous section Current section 0.001 0.0001 Following section t/h Fig. 63: Graphical representation of the course of the control set value In order to protect the product, a every drying section.

Freeze-dryer EPSILON 2-10D LSCplus 6 Operation this limit, the shelf heater will be switched off in order to prevent the product from thawing due to excessive energy input by the shelf temperature control system. The LyoControl value is checked only during the main and final drying phases. p pressure increase test (option): Depending on the selected mode, the pressure increase test can also be used as a condition for switching to the next section (see (see chapter 6.5.3.

Freeze-dryer EPSILON 2-10D LSCplus 6 Operation Pos: 157 /20 0 Ch rist/3 60 G T-BA L abo r-Pilot (STANDARDMODU LE)/0 60 Bet rieb/ LSCplus/ 060 -00 50- 003 2-0 011 Prog ra mm erstell en Epsilo n @ 25\ mod _14 0498 399 771 8_6 8.do cx @ 1 839 70 @ 4 @ 1 6.5.3.1 Creating a program To create a new program: • Press the button "New program" in the main window "Program". The dialog box that is displayed offers various different program templates.

Freeze-dryer EPSILON 2-10D LSCplus 6 Operation “Program” buttons: 1 "Program" 2 "Program name" 3 "Show diagram" 4 "Insert section" 5 "Delete section" 6 7 Button for calling up more functions and set values "Save" Fig. 66: Editing a blank program template • • The button “Delete section” (5) can be used to delete sections. The button ">>more" (6) can be used to enter more functions and set values in a program-related manner, depending on the type of freezedryer (see the sections below).

Freeze-dryer EPSILON 2-10D LSCplus 6 Operation Button ">>more" The button ">>more" can be used to enter more functions and set values in a program-related manner. Fig. 67: Selection of program-related functions and set values Vacuum pump warm-up see chapter 6.5.3 - "Freeze-drying with the PGMplus programmer module" Option: Pressure increase test (only with the double-chamber method) The pressure increase test can only be performed when the freeze-dryer is equipped with an intermediate valve.

Freeze-dryer EPSILON 2-10D LSCplus 6 Operation • • and chamber vacuum. Thus, the progress condition for switching to the next section is fulfilled and the next section will be initiated. If the condition for switching to the next section is not fulfilled, a process message will be issued, the current section will be extended, and further pressure increase tests will be executed periodically until the condition is fulfilled.

Freeze-dryer EPSILON 2-10D LSCplus 6 Operation Option: Comparative pressure measurement (see chapter 6.6 - "Optional extensions and special equipment") The indication of the measurement value "dp Comp" can be configured in chapter 6.5.1.1 - "Main window "Manual"" under "Actual values of the current process" in the dialog box "Select actual value". NOTE The comparative pressure measurement can be activated or deactivated by pressing the button in the dialog box.

Freeze-dryer EPSILON 2-10D LSCplus 6 Operation Option: Aeration, stoppering, storage (see chapter 6.6 - "Optional extensions and special equipment") 1 2 3 4 5 Button for selecting the variant Set value "Aeration" Set value "Aeration after stoppering" Set value "Stoppering" Set value "Storage" Fig.

Freeze-dryer EPSILON 2-10D LSCplus 6 Operation stated under "Aeration after stoppering" (see the illustration above, item 3). Then, the shelves are moved apart into the drying position. In the second step, the system is aerated up to atmospheric pressure.

Freeze-dryer EPSILON 2-10D LSCplus 6 Operation If the vacuum control system of the freeze-dryer uses a regulated gas admission (injection), the preselected medium will be used for this purpose. If the freeze-dryer is equipped with the "Aeration, Stoppering, Storage" option, the preselected medium will be used for the aeration up to stoppering (backfilling) as well as for the final aeration up to atmospheric pressure.

Freeze-dryer EPSILON 2-10D LSCplus 6 Operation Fig. 72: Information concerning the program template (here: a recipe for nutrient media/bacteria) After the conformation of the information, the program template will be displayed. • Similar to a blank program, sections can be added or deleted and the set values can be adapted accordingly. Pos: 158 /01 0 Univ ersal mod ule/L eerz eile @ 0\m od_ 120 211 624 450 0_0.

Freeze-dryer EPSILON 2-10D LSCplus 6 Operation 6.5.3.3 Copying a program If a new program is to be created based on an already existing program, the already existing program can be copied. A free program storage location must be available for this purpose. • Select the program to be copied from the list in the main window "Program". • Press the button with the program name in order to call up a window with the program data.

Freeze-dryer EPSILON 2-10D LSCplus 6 Operation Fig. 74: The freeze-drying process can be started with the aid of the button “Program start”. NOTE • During the freeze-drying process, the description of the active program can also be called up from the main window "Program" and via the button "Info". • When the "Stop" button is pressed, the freeze-dryer switches to the standby – manual freezing mode. The program starts with section 02 "Freezing" by default.

Freeze-dryer EPSILON 2-10D LSCplus 6 Operation Pos: 168 /20 0 Ch rist/3 60 G T-BA L abo r-Pilot (STANDARDMODU LE)/0 60 Bet rieb/ LSCplus/ 060 -00 60 Optio nale Erw eite run gen und S onde ra usstatt ung en Epsil on- --- -- --- -- --- --- -- --- -- --- --- -- @ 25 \mo d_1 404 984 006 843_ 68. docx @ 18 4054 @ 2 @ 1 6.6 Optional extensions and special equipment Aeration, stoppering, storage see also chapter 6.5.3.

Freeze-dryer EPSILON 2-10D LSCplus 6 Operation USB process recording see also chapter 6.5.2 - "Manual freeze-drying", section "Dialog box "Tools"" This feature enables the recording of a running process on a USB storage medium. After the end of the process recording, the process data can be viewed on the PC with LyoLogplus and they can be printed. It is also possible to import the data directly into an Excel file. Preselection of the aeration medium see also chapter 6.5.1.

Freeze-dryer EPSILON 2-10D LSCplus 6 Operation LPCplus SCADA system The Christ LPCplus system consists of the Supervisory Control And Data Acquisition (SCADA) software program by Martin Christ Gefriertrocknungsanlagen GmbH and a dedicated PC. The system is connected to the LSCplus controller of the freeze-dryer via Ethernet and provides the operation of all of the freeze-drying functions as well as process recording (measurement data and process events), process documentation and data backup.

Freeze-dryer EPSILON 2-10D LSCplus 7 Malfunctions and error correction Pos: 174 /20 0 Ch rist/3 60 G T-BA L abo r-Pilot (STANDARDMODU LE)/0 70 Stö run gen und Fe hlers uche /07 0 Stö run gen und Fe hlers uche == == === == == === == == === == == == @ 25\ mo d_14 049 840 560 39_ 68.d ocx @ 184 111 @ 1 @ 1 7 Malfunctions and error correction Malfunctions are displayed in the dialog box "Process & equipment messages" (see chapter 7.2 - "Process and error messages").

Freeze-dryer EPSILON 2-10D LSCplus 7 Malfunctions and error correction Type of error Possible reason Correction The displayed vacuum value is not correct • Incorrect calibration • • The vacuum sensor is soiled (e.g. due to water residues). The vacuum sensor is defective. • • • Calibrate the vacuum sensor (see the separate operating instructions of the vacuum sensor). Clean the vacuum sensor. Check the vacuum display with the aid of a reference device (if available). • see chapter 7.1.2.

Freeze-dryer EPSILON 2-10D LSCplus 7 Malfunctions and error correction Pos: 181 /20 0 Ch rist/3 60 G T-BA L abo r-Pilot (STANDARDMODU LE)/0 70 Stö run gen und Fe hlers uche /07 0-0 010 -00 20 Kei n au sreic hend es Vak uum @ 2 5\mo d_1 404 984 060 039 _68. docx @ 18 416 7 @ 3 @ 1 7.1.2 Insufficient vacuum The vacuum checks must be carried out when the ice condenser is frozen. NOTE Pos: 182 /01 0 Univ ersal mod ule/L eerz eile @ 0\m od_ 120 211 624 450 0_0.

Freeze-dryer EPSILON 2-10D LSCplus 7 Malfunctions and error correction Pos: 185 /20 0 Ch rist/3 60 G T-BA L abo r-Pilot (STANDARDMODU LE)/0 70 Stö run gen und Fe hlers uche /07 0-0 010 -00 20- 0020 Belüf tun gsven til, Me dien abla ufven til LSCplus (au ße r Epsilo n 2- 4) @ 25\ mo d_1 4049 840 624 97_ 68.d ocx @ 184 195 @ 4 @ 1 7.1.2.2 Aeration valve, media drain valve A malfunction of the aeration valve or the media drain valve may have several causes.

Freeze-dryer EPSILON 2-10D LSCplus 7 Malfunctions and error correction Pos: 193 /20 0 Ch rist/3 61 G T-BA L abo r-Pilot (PROJEKTE)/Epsilo n Sta nda rd/0 70 Stö run gen und Fe hler such e/07 0-0 010 -00 31 Eisko nde nsat or- und Stellfläc hent emp era tur E psilon @ 25\ mo d_1 4049 846 659 83_ 68.d ocx @ 185 861 @ 3 @ 1 7.1.3 Insufficient ice condenser temperature Ensure sufficient ventilation.

Freeze-dryer EPSILON 2-10D LSCplus 7 Malfunctions and error correction Pos: 198 /20 0 Ch rist/3 60 G T-BA L abo r-Pilot (STANDARDMODU LE)/0 70 Stö run gen und Fe hlers uche /07 0-0 031 Kont akt im S ervice fall_Epsilo n @ 25\m od_ 140 498 406 970 5_68 .docx @ 1 842 93 @ 2 @ 1 7.3 Service contact In the event of queries, malfunctions, or spare part enquiries: From Germany: Contact Martin Christ Gefriertrocknungsanlagen GmbH An der Unteren Söse 50 37520 Osterode (Germany) Tel.

Freeze-dryer EPSILON 2-10D LSCplus 8 Maintenance and service Pos: 201 /20 0 Ch rist/3 60 G T-BA L abo r-Pilot (STANDARDMODU LE)/0 80 Wa rtun g u nd In stan dhalt ung/ 080 Wa rtun g un d Ins tan dhalt ung == === == == === == == === == == == == @ 25\ mod _14 049 840 9570 4_6 8.d ocx @ 184 307 @ 1 @ 1 8 Maintenance and service The freeze-dryer and the accessories are subject to high mechanical stress. Thorough maintenance performed by the user extends the service life and prevents premature failure.

Freeze-dryer EPSILON 2-10D LSCplus 8 Maintenance and service Pos: 206 /20 0 Ch rist/3 60 G T-BA L abo r-Pilot (STANDARDMODU LE)/0 80 Wa rtun g u nd In stan dhalt ung/ 080 -00 10- 001 0-0 010 Eiskon dens ato rkam me r (a uß er Epsil on 2 -4) @ 2 5\m od_ 1404 984 098 898 _68. docx @ 18 434 9 @ 4 @ 1 8.1.1.1 Ice condenser chamber Before each start-up, ensure that the ice condenser chamber is free from water residues. • Open the media drain valve to drain off any liquid. Then, close the valve.

Freeze-dryer EPSILON 2-10D LSCplus 8 Maintenance and service Pos: 210 /20 0 Ch rist/3 60 G T-BA L abo r-Pilot (STANDARDMODU LE)/0 80 Wa rtun g u nd In stan dhalt ung/ 080 -00 10- 001 0-0 030 Belüf tung sventil, Me dien ablau fventil LSCplus (au ße r Epsilon 2- 4) @ 25\ mod _14 049 841 011 41_ 68.d ocx @ 184 377 @ 4 @ 1 8.1.1.3 1 2 3 Aeration valve, media drain valve Contaminants such as product residues may lead to an insufficient vacuum.

Freeze-dryer EPSILON 2-10D LSCplus 8 Maintenance and service Pos: 214 /20 0 Ch rist/3 60 G T-BA L abo r-Pilot (STANDARDMODU LE)/0 80 Wa rtun g u nd In stan dhalt ung/ 080 -00 10- 002 0 Vak uum pu mpe @ 25 \mo d_1 404 984 1034 28_ 68. docx @ 18 4405 @ 3 @ 1 8.1.2 Vacuum pump Please refer to the separate operating manual of the vacuum pump! NOTE The stress of the vacuum pump in conjunction with a freeze-dryer is usually not very high.

Freeze-dryer EPSILON 2-10D LSCplus 8 Maintenance and service Pos: 218 /20 0 Ch rist/3 60 G T-BA L abo r-Pilot (STANDARDMODU LE)/0 80 Wa rtun g u nd In stan dhalt ung/ 080 -00 10- 004 0 Vak uum mess sond e @ 25\ mod _14 0498 410 561 0_6 8.do cx @ 1 844 33 @ 3 @ 1 8.1.4 Vacuum sensor Please refer to the separate operating manual of the vacuum sensor! NOTE The vacuum sensor has only a limited service life. Especially carboncontaining substances, e.g. alcoholic compounds, reduce the service life extremely.

Freeze-dryer EPSILON 2-10D LSCplus 8 Maintenance and service Pos: 222 /20 0 Ch rist/3 60 G T-BA L abo r-Pilot (STANDARDMODU LE)/0 80 Wa rtun g u nd In stan dhalt ung/ 080 -00 20 Desinf ektion von Tr ockn ungsk am mer und Zu beh ör @ 25\ mo d_1 4049 841 078 51_ 68.d ocx @ 184 461 @ 2 @ 1 8.2 Disinfection of the drying chamber and accessories • • • • Use commercially-available disinfectants such as, for example, Incidur , Meliseptol , Sagrotan , Buraton , or Terralin (available at specialised trade).

Freeze-dryer EPSILON 2-10D LSCplus 8 Maintenance and service Pos: 224 /20 0 Ch rist/3 61 G T-BA L abo r-Pilot (PROJEKTE)/Epsilo n Sta nda rd/0 80 Wa rtu ng u nd I nstan dhal tung /08 0-0 021 Wart ung splan Epsilon 6er 10 er @ 25\ mod _14 049 846 8138 5_6 8.d ocx @ 1859 31 @ 2 @ 1 8.

Freeze-dryer EPSILON 2-10D LSCplus 8 Maintenance and service System/ Component Inspection Detail / Part before start Refrigeration System daily Ice formation Electrical Installation replace X operation calibration cleaning X X X X X X X X X X X Clean regulation device X X X Instrumentation Vacuum sensor(s) T emperature points at FD Pressure sensors chamber Product temperature Level switches Solenoid valves Leakages Max pressure reading Oil in reservoir Hydraulic hoses T ravel speed cyl

Freeze-dryer EPSILON 2-10D LSCplus 8 Maintenance and service Pos: 226 /20 0 Ch rist/3 60 G T-BA L abo r-Pilot (STANDARDMODU LE)/0 80 Wa rtun g u nd In stan dhalt ung/ 080 -00 31 Inst and haltu ngsa rbeit en Epsil on @ 25\ mod _14 049 8410 998 2_6 8.do cx @ 1844 89 @ 2 @ 1 8.4 Service In the event of service work that requires the removal of the panels, there is a risk of electric shock or mechanical injury. Only qualified specialist personnel is authorised to perform this service work.

Freeze-dryer EPSILON 2-10D LSCplus 8 Maintenance and service 1. Declaration of decontamination As a certified company and due to the legal regulations for the protection of our employees and of the environment, we are obliged to certify the harmlessness of all incoming goods. For this purpose, we require a declaration of decontamination. • The form must be filled in completely and signed by authorised and specialised personnel only.

Freeze-dryer EPSILON 2-10D LSCplus 9 Disposal Pos: 232 /20 0 Ch rist/3 60 G T-BA L abo r-Pilot (STANDARDMODU LE)/0 90 Ents org ung/ 090 Ents org ung === == == == === == == === == == === == == === == == === == @ 2 5\mo d_1 404 984 138 903 _68. docx @ 18 451 7 @ 1 @ 1 9 Disposal Pos: 233 /20 0 Ch rist/3 60 G T-BA L abo r-Pilot (STANDARDMODU LE)/0 90 Ents org ung/ 090 -00 10 Entso rgu ng d er G efri ertr ockn ungs anlag e @ 25\ mod _140 498 414 112 2_6 8.doc x @ 1 845 31 @ 2 @ 1 9.

Freeze-dryer EPSILON 2-10D LSCplus 10 Technical data Pos: 238 /20 0 Ch rist/3 61 G T-BA L abo r-Pilot (PROJEKTE)/Epsilo n 2 -10D LSCplus St and ard/ 100 Tec hnisc he Dat en/ 100 T echnisc he Da ten E 2-1 0D== == == === == == === == == == === == == @ 25\ mo d_14 049 849 173 48_ 68.

Freeze-dryer EPSILON 2-10D LSCplus 10 Technical data Connection requirements Electrical connection: 3 x 400 V / 50 Hz (other supply data on request) Protection class: I IP protection categoryaccording to DIN 60529: 11 Nominal power - with vacuum pump Pfeiffer DUO 10 (3 ph): 6.8 kVA Nominal current: 12.0 A Mains fuse: 16.

Freeze-dryer EPSILON 2-10D LSCplus 10 Technical data Shelves Shelf width: 350 R-vials 2R 4R 6R 8R 10R 15R 20R 25R 30R Shelf length: 400 mm 35 45 40 45 45 60 55 65 75 15 Ø mm 16 16 22 22 24 24 30 30 30 Shelf Number of shelves Area Distance The data indicate the maximum loading.

Freeze-dryer EPSILON 2-10D LSCplus 11 Appendix Pos: 246 /20 0 Ch rist/3 60 G T-BA L abo r-Pilot (STANDARDMODU LE)/1 10 Anh ang /011 0 Anh ang == == === == == == === == == === == == === == == === == == === == == = @ 25\m od_ 140 498 417 799 4_68 .docx @ 1 846 01 @ 1 @ 1 11 Appendix Pos: 247 /20 0 Ch rist/3 60 G T-BA L abo r-Pilot (STANDARDMODU LE)/1 10 Anh ang /011 0-0 010 M athe matisc he Zusa mm enh äng e @ 2 5\m od_ 140 498 4178 952 _68 .docx @ 1 8461 5 @ 2 @ 1 11.

Freeze-dryer EPSILON 2-10D LSCplus 11 Appendix Pos: 249 /20 0 Ch rist/3 61 G T-BA L abo r-Pilot (PROJEKTE)/Epsilo n 2 -10D LSCplus St and ard/ 110 Anha ng/0 110 -00 30 K onfo rmit ätse rklär ung E2 -10D _LSCplu s @ 2 5\m od_ 140 498 4925 366 _68 .docx @ 1 8647 5 @ 2 @ 1 11.2 EC-Declaration of conformity Pos: 250 /01 0 Univ ersal mod ule/Seit enwec hsel @ 0\m od_ 120 211 624 4312 _0. docx @ 10 5 @ @ 1 Version 04/2013, Rev. 1.

Freeze-dryer EPSILON 2-10D LSCplus 11 Appendix Pos: 251 /20 0 Ch rist/3 60 G T-BA L abo r-Pilot (STANDARDMODU LE)/1 10 Anh ang /011 0-0 040 Spa nnu ngsriss - u nd Ch emik alienb estä ndigk eit Plexiglas @ 2 5\m od_1 404 984 180 960 _68. docx @ 18 464 3 @ 2 @ 1 110 Version 04/2013, Rev. 1.

Freeze-dryer EPSILON 2-10D LSCplus 11 Appendix 11.3 Resistance to stress cracking and chemical influences "Plexiglas" Version 04/2013, Rev. 1.

Freeze-dryer EPSILON 2-10D LSCplus 11 Appendix 112 Version 04/2013, Rev. 1.

Freeze-dryer EPSILON 2-10D LSCplus 11 Appendix Version 04/2013, Rev. 1.

Freeze-dryer EPSILON 2-10D LSCplus 11 Appendix 114 Version 04/2013, Rev. 1.

Freeze-dryer EPSILON 2-10D LSCplus 11 Appendix Version 04/2013, Rev. 1.

Freeze-dryer EPSILON 2-10D LSCplus 11 Appendix 116 Version 04/2013, Rev. 1.

Freeze-dryer EPSILON 2-10D LSCplus 11 Appendix Version 04/2013, Rev. 1.

Freeze-dryer EPSILON 2-10D LSCplus 11 Appendix 118 Version 04/2013, Rev. 1.

Freeze-dryer EPSILON 2-10D LSCplus 11 Appendix Version 04/2013, Rev. 1.

Freeze-dryer EPSILON 2-10D LSCplus 11 Appendix 120 Version 04/2013, Rev. 1.

Freeze-dryer EPSILON 2-10D LSCplus 11 Appendix Version 04/2013, Rev. 1.

Freeze-dryer EPSILON 2-10D LSCplus 11 Appendix 122 Version 04/2013, Rev. 1.

Freeze-dryer EPSILON 2-10D LSCplus 11 Appendix Version 04/2013, Rev. 1.

Freeze-dryer EPSILON 2-10D LSCplus 11 Appendix 124 Version 04/2013, Rev. 1.

Freeze-dryer EPSILON 2-10D LSCplus 11 Appendix Version 04/2013, Rev. 1.

Freeze-dryer EPSILON 2-10D LSCplus 11 Appendix 126 Version 04/2013, Rev. 1.

Freeze-dryer EPSILON 2-10D LSCplus 11 Appendix Pos: 252 /01 0 Univ ersal mod ule/Seit enwec hsel @ 0\m od_ 120 211 624 4312 _0. docx @ 10 5 @ @ 1 Version 04/2013, Rev. 1.

Freeze-dryer EPSILON 2-10D LSCplus 11 Appendix Pos: 253 /01 0 Univ ersal mod ule/9 00 Gl ossa r GT Epsilon == === == == === == == == === == == === == == === == == === == @ 2 6\mo d_1 404 986 130 353 _68. docx @ 18 891 7 @ 1 @ 1 128 Version 04/2013, Rev. 1.

Freeze-dryer EPSILON 2-10D LSCplus 12 Glossary 12 Glossary Aeration, stoppering, storage "Aeration, stopperting, storage" means automated sealing of the product vials with previously inserted rubber stoppers under partial vacuum and subsequent storage on the shelves at defined conditions as an integral part of a freeze-drying program.

Freeze-dryer EPSILON 2-10D LSCplus 12 Glossary Pressure increase test The pressure increase test can only be carried out with double-chamber method. During the pressure increase test, the intermediate valve prevents the flow of steam from the drying chamber to the ice condenser so that the water vapour of the sublimation cannot flow off. The result is a more or less distinct pressure increase that is measured in the product chamber.

Freeze-dryer EPSILON 2-10D LSCplus Index 13 Index A Access protection....................................... 60 Accessories ................................... 11, 27, 98 Accident prevention ................................... 25 Actual values of the current process .......... 47 Administration ............................................ 58 Adsorption filter .......................................... 35 Aeration medium, preselection ............. 55, 86 Aeration valve ....................................

Freeze-dryer EPSILON 2-10D LSCplus Index Dialog box "Schematic system diagram ..... 49 Dialog box "Tools"...................................... 47 Dimensions ................................................ 31 Direct hazard to the life and health ............. 24 Disinfectants .............................................. 99 Disinfection of the drying chamber and accessories ............................................ 99 Displayed vacuum value is not correct ....... 89 Disposal of the freeze-dryer ......

Freeze-dryer EPSILON 2-10D LSCplus Index LSCplus control system ............................. 44 LyoBalance weighing system ............... 49, 86 LyoControl LCplus measuring system ........ 86 LyoControl-Rx ............................................ 72 LyoLogplus data logging software .............. 86 M Main drying ................................................ 21 Main window "?"......................................... 68 Main window "Manual" ...............................

Freeze-dryer EPSILON 2-10D LSCplus Index Procedures in the event of hazards and accidents ................................................ 29 Process and equipment messages ............ 50 Process and error messages ..................... 92 Process data .............................................. 45 Product temperature measurement system WTMplus ................................................ 86 Program list................................................ 53 Program sections ...........................

Freeze-dryer EPSILON 2-10D LSCplus Index Transport ................................................... 31 Transport safety devices ............................ 32 Type................................................... 16, 105 Ventilation ............................................ 34, 92 Viewing or editing the set values ................ 69 Volumetric flow rate ................................. 106 U W Unit of measurement.................................. 55 Unit test ................................