Technical information

TESTING SECTION: PART 3

Assuming there were no fireworks upon powering on, you can begin

taking measurements.

Set your meter to AC volts, with the negative lead grounded on the

chassis, and test V1 pins 4, 5 and 9. You should measure

approximately 3.15V AC. It is common for this to run slightly high, as

seen here measured at 3.24V AC.

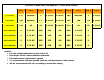

Measure for the same reading on V2 and V3. Also V4 - V7, pins 2

and 8. Reference the voltage chart in the APPENDIX for an overview

of tube and terminals that should have 3.15V AC present.

If all test well, you know that each tube will be supplied the correct

heater current. You should see the 12AX7 preamp tubes glowing.

Next, set your meter to DC volts 100V range or higher

and measure for negative DC bias voltage on each of the

5.6kΩ grid resistors attached to PIN 5 of V4 –V7.

You should measure up to –50V DC on each resistor if

you are using EL34’s, up to –65V DC for 6550 specs.

It is essential that this voltage is present on PIN 5 of

output each tube. To apply high voltage to the tubes

without bias voltage would almost certainly damage

them.

CAUTION! UP TO 100V DC

With heater and bias voltages correct, it’s time to throw the STANDBY switch and apply high voltage

to the circuit. With only the preamp tubes installed, the high voltage will read somewhat high. This is

normal and it will level off when the output tubes are installed and biased.

Without further ado, turn the STANDBY switch to ON.

High voltage AC is now traveling from the PT, through

the STANDBY switch and on to the diode bridge for

rectification.

Set your meter to AC 500V and measure approx 180V

AC at the terminals on the far RIGHT of the board, as

shown here. Next, set your meter to DC 500V and

measure approx 480V DC at the terminal marked “+”

on the diagram. Slightly higher readings are normal.

CAUTION! 500V DC