User guide

Table Of Contents

- 169000_RevF - Final - A Series OM Cover MACDON for WEB.pdf

- 169000_RevF - A Series OM FINAL w DofC for WEB

- back page

- new cover_WEB.pdf

- toc

- Model and Serial Number

- 1Safety

- 2Definitions

- 3Component Identification

- 4Specifications

- 5Operation

- 5.1Owner/Operator Responsibilities

- 5.2Operational Safety

- 5.3Tractor Setup: Pull-Type

- 5.4Mower Conditioner / Tractor Hook-Up: Pull-Type

- 5.5Mower Conditioner / Tractor Unhook: Pull-Type

- 5.6Header Attachment: Self-Propelled

- 5.7Configure Reverser Valve Jumper Hose

- 5.8Header Detachment: Self Propelled

- 5.9Transporting Header/Mower Conditioner

- 5.10Break-In Period

- 5.11Preseason Check

- 5.12Daily Start-Up Check

- 5.13Shutdown Procedure

- 5.14Engaging the Power Take-Off (PTO): Pull-Type

- 5.15Lift Cylinder Lockouts

- 5.16Steering the Pull-Type Mower Conditioner

- 5.17Unplugging the Header/Mower Conditioner

- 5.17.1Unplugging Conditioner and Knife: Pull-Type

- 5.17.2Unplugging Conditioner: Self-Propelled

- 5.17.3Unplugging Conditioner and Knife: Self-Propelled

- 5.18Header Operation

- 5.18.1Lean Bar Position

- 5.18.2Auger Speed

- 5.18.3Reel Speed

- 5.18.4Auger Position

- 5.18.5Reel Position

- 5.18.6Adjusting Tine Aggressiveness

- 5.18.7Cutting Height

- 5.18.8Header Angle

- 5.18.9Flotation

- 5.18.10Adjusting Feed Pan and Rock Drop Tine Position

- 5.18.11Hay Conditioner

- 5.18.12Adjusting Roll Tension

- 5.18.13Forming Shields

- 5.18.14Tall Crop Dividers

- 5.18.15Ground Speed

- 5.18.16Grass Seed Windrowing

- 5.18.17Haying Tips

- 5.18.18Storage

- 6Maintenance and Servicing

- 6.1Preparation for Servicing

- 6.2Recommended Safety Procedures

- 6.3Maintenance Specifications

- 6.4Driveshields

- 6.5Lift Cylinder Lock-Outs

- 6.6Lubrication

- 6.7Hydraulics

- 6.8Knife and Knife Drive

- 6.8.1Replacing Knife Section

- 6.8.2Sickle Removal

- 6.8.3Installing Knife

- 6.8.4Sickle Head Bearing Removal

- 6.8.5Sickle Head Bearing Installation

- 6.8.6Spare Sickle

- 6.8.7Sickle Guards

- 6.8.8Sickle Hold-Downs

- 6.8.9Sickle Drive Belt: A30-S

- 6.8.10Sickle Drive Belts: A30-D

- 6.8.11Sickle Drive Belts: A40-D

- Adjusting Tension on Knife Drive Timing Belt – A40-D Left Side

- Adjusting Tension on Knife Drive Timing Belt – A40-D Left Side

- Removal: A40-D LH Sickle Drive Timing Belt

- Removal: A40-D LH Sickle Drive Timing Belt

- Installing Knife Drive Timing Belts – A40-D Left Side

- Installing Knife Drive Double V-Belts – A40-D Left Side

- Adjusting Tension on Knife Drive Belt – A40-D Right Side

- Removing Knife Drive Belt – A40-D Right Side

- Installing Knife Drive Belt – A40-D Right Side

- 6.8.12Sickle Drive Belt Timing Adjustment

- 6.8.13Knife Drive Box

- 6.9Reel Drive Belts: A30-S, A30-D

- 6.10Reel Tines and Tine Bar Bearings – A30-D

- 6.11Reel and Reel Drive: A30-S, A30-D

- 6.12Reel and Reel Drive: A40-D

- 6.13Auger and Auger Drive – A30-D

- 6.14Auger and Auger Drive – A40-D

- 6.15Conditioner

- 6.15.1Changing Gearbox Oil

- 6.15.2Removing Forming Shield

- 6.15.3Disassembling Forming Shield

- 6.15.4Assembling Forming Shield

- 5.Attach adjuster rods (B) to side deflectors (C) with lynch pin (A).

- 6.15.5Installing Forming Shield

- 6.15.6Hydraulic Drive Motor Removal: All Models

- 6.15.7Hydraulic Drive Motor Installation: All Models

- 6.15.8Gearbox Removal: A30-S

- 6.15.9Gearbox Installation: A30-S

- 6.15.10Gearbox Removal: A30-D

- 6.15.11Gearbox Installation: A30-D

- 6.15.12Gearbox Removal: A40-D

- 6.15.13Gearbox Installation: A40-D

- 6.16Wheels and Tires – A30-D

- 6.17Replacing Skid Shoe Wear Plate

- 6.18Gauge Rollers

- 6.19Maintaining Electrical System

- 6.20Maintenance Schedule

- 7Troubleshooting

- 8Options and Attachments

- 9Unloading and Assembly

- Model and Serial Number

- toc

SECTION 5 SPECIFICATIONS

169000 28 Revision F

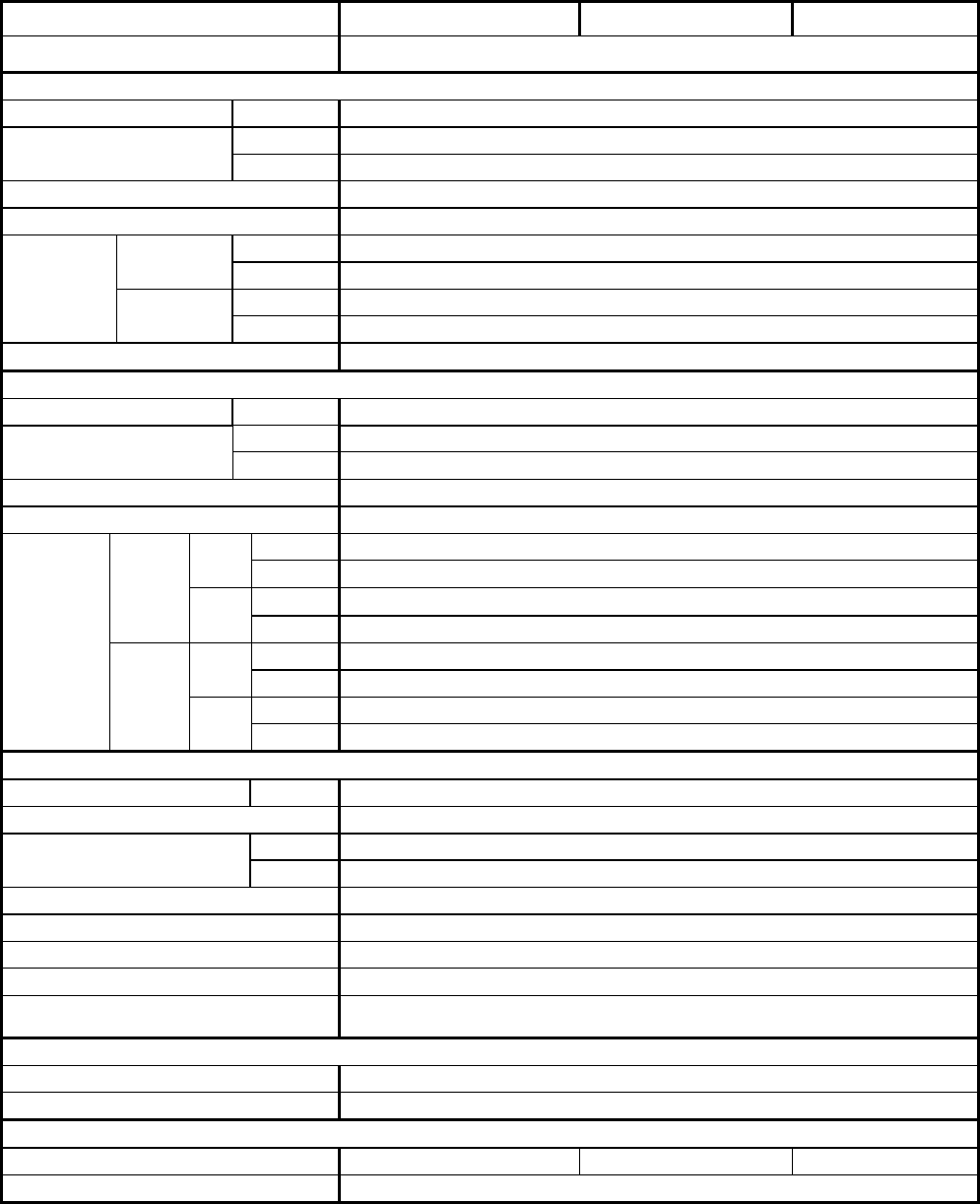

PULL-TYPE HEADERS (cont’d)

NOTES: 1. Specifications and design are subject to change without notice or obligation to revise previously sold units.

HEADER SIZE 14 FT 16 FT 18 FT

HEADER MODEL A30-D

AUGER

Drive Mechanical 2 Belts To Chain

Size

Tube 10 in. (254 mm) O.D

Flighting 20 in. (508 mm) O.D., 0.25 in. (6 mm) thick.

Type

Undershot, Center Feed. Rubber Finger Feed.

Stripper Bars

3 Per Side

Speed

(rpm)

20T Sprocket

No Load 275

Load 265

19T Sprocket

No Load 261

Load 252

Delivery Opening

95.7 in. (2430 mm)

REEL

Drive Mechanical 2 Belts From Auger To Chain Final Drive

Type

Bats 5-Bat (6-Bat Optional)

Tines Steel: 0.25 in. (6 mm) Diameter

Tine Bar Bearings

Replaceable Polyethylene

Radius (to tine tip)

22 in. (540 mm)

Speed

(rpm)

20T

Sprocket

20T

Auger

No Load 74

Load 71

19T

Auger

No Load 70

Load 68

19T

Sprocket

20T

Auger

No Load 70

Load 68

19T

Auger

No Load 67

Load 64

CONDITIONER

Drive Hydraulic M44 (44cc) Motor To Enclosed Gearbox

Roll Type

Intermeshing Steel Bars

Roll Diameter

Bars 9.17 in. (233 mm) O.D.

Tube 6.63 in. (168 mm) O.D.

Roll Length

102 in. (2590 mm)

Roll Speed (rpm)

No Load - 766 Load - 736

Swath Width

36 in. (915 mm) to 100 in. (2540 mm)

Unplugging Assist

Rolls Open As Header Lifts. Rolls Can Open to 4.25 in. (108 mm) During Operation

Forming Shields

Header Mounted Adjustable Baffle and Side Deflector System

For 36 in. (915 mm) to 100 in. (2540 mm) Swath Width

OPERATING SPEED

Recommended Cutting 5 mph (8 km/hr)

Recommended Transport 20 mph (30 km/hr)

TRACTOR REQUIREMENTS

Power (minimum) 90 HP (68 kW) 110 HP (83 kW) 130HP (98 kW)

Hydraulics 2000 psi (13,714 kPa)