Datasheet

Table Of Contents

- Features

- Applications

- Description

- Typical Application

- Absolute Maximum Ratings

- Pin Configuration

- Order Information

- Electrical Characteristics

- Typical Performance Characteristics

- Pin Functions

- Functional Diagram

- Operation

- Applications Information

- Typical Applications

- Package Description

- Revision History

- Typical Application

- Related Parts

LTC3608

13

3608fc

applications inForMation

Minimum Off-time and Dropout Operation

The minimum off-time, t

OFF(MIN)

, is the smallest amount

of time that the LTC3608 is capable of turning on the bot-

tom MOSFET, tripping the current comparator and turning

the MOSFET back off. This time is generally about 320ns.

The minimum off-time limit imposes a maximum duty

cycle of t

ON

/(t

ON

+ t

OFF(MIN)

). If the maximum duty cycle

is reached, due to a dropping input voltage for example,

then the output will drop out of regulation. The minimum

input voltage to avoid dropout is:

V

IN(MIN)

= V

OUT

t

ON

+ t

OFF(MIN)

t

ON

A plot of Maximum Duty Cycle vs Frequency is shown in

Figure 3.

Setting

the Output Voltage

The LTC3608 develops a 0.6V reference voltage between

the feedback pin, V

FB

, and the signal ground as shown in

Figure 6. The output voltage is set by a resistive divider

according to the following formula:

V

OUT

= 0.6V 1+

R2

R1

⎛

⎝

⎜

⎞

⎠

⎟

To improve the frequency response, a feed forward capaci-

tor C1 may also be used. Great care should be taken to

route the V

FB

line away from noise sources, such as the

inductor or the SW line.

Inductor

Selection

Given the desired input and output voltages, the induc-

tor value and operating frequency determine the ripple

current:

ΔI

L

=

V

OUT

f L

⎛

⎝

⎜

⎞

⎠

⎟

1−

V

OUT

V

IN

⎛

⎝

⎜

⎞

⎠

⎟

Lower ripple current reduces core losses in the inductor,

ESR losses in the output capacitors and output voltage

ripple. Highest efficiency operation is obtained at low

frequency with small ripple current. However, achieving

this requires a large inductor. There is a tradeoff between

component size, efficiency and operating frequency.

A reasonable starting point is to choose a ripple current

that is about 40% of I

OUT(MAX)

. The largest ripple current

occurs at the highest V

IN

. To guarantee that ripple current

does not exceed a specified maximum, the inductance

should be chosen according to:

L =

V

OUT

f ΔI

L(MAX)

⎛

⎝

⎜

⎞

⎠

⎟

1−

V

OUT

V

IN(MAX)

⎛

⎝

⎜

⎞

⎠

⎟

Figure 3. Maximum Switching Frequency vs Duty Cycle

2.0

1.5

1.0

0.5

0

0 0.25 0.50 0.75

3608 F03

1.0

DROPOUT

REGION

DUTY CYCLE (V

OUT

/V

IN

)

SWITCHING FREQUENCY (MHz)

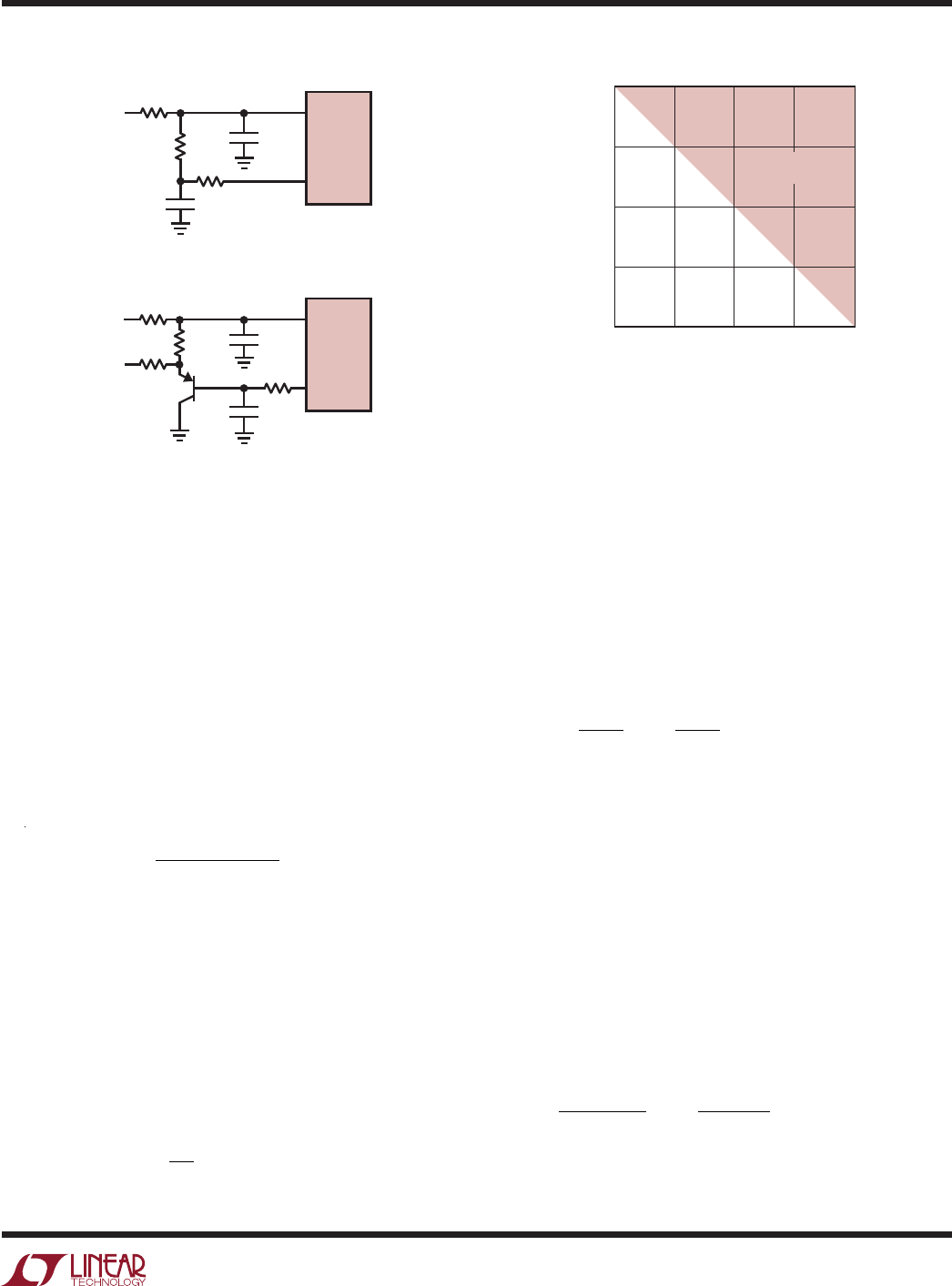

Figure 2. Correcting Frequency Shift with Load Current Changes

C

VON

0.01µF

R

VON2

100k

R

VON1

30k

C

C

V

OUT

R

C

(2a)

(2b)

V

ON

I

TH

LTC3608

C

VON

0.01µF

R

VON2

10k

Q1

2N5087

R

VON1

3k

10k

C

C

3608 F02

V

OUT

INTV

CC

R

C

V

ON

I

TH

LTC3608