Installation Manual

Table Of Contents

- Safety Instructions

- Introduction

- Unit Nomenclature

- General Data

- Specifications

- Typical Multi F/Multi F Max Systems

- Refrigerant Piping Requirements

- General Installation Guidelines

- Inspection

- Refrigerant Piping

- Piping Materials and Handling

- Piping Preparation

- Piping Connections

- Piping Insulation

- Drain Piping

- Electrical Wiring

- Power Wiring Specifications and Best Practices

- Power Wiring Specifications and Best Practices/Controller Options

- Indoor Unit Electrical Connections Guidelines

- Indoor Unit Electrical Connections Procedure

- Self Diagnosis Functions

- LG SIMS - Self Diagnosis Functions

- Optional Wall-Mounted Sensor and Controller

- Troubleshooting

- Cautions for Refrigerant leaks

- Installation CHECKLIST

27

Installation Manual

Due to our policy of continuous product innovation, some specifications may change without notification.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

MA

X

MUL

TI

F

MUL

TI

F

Pipe Supports

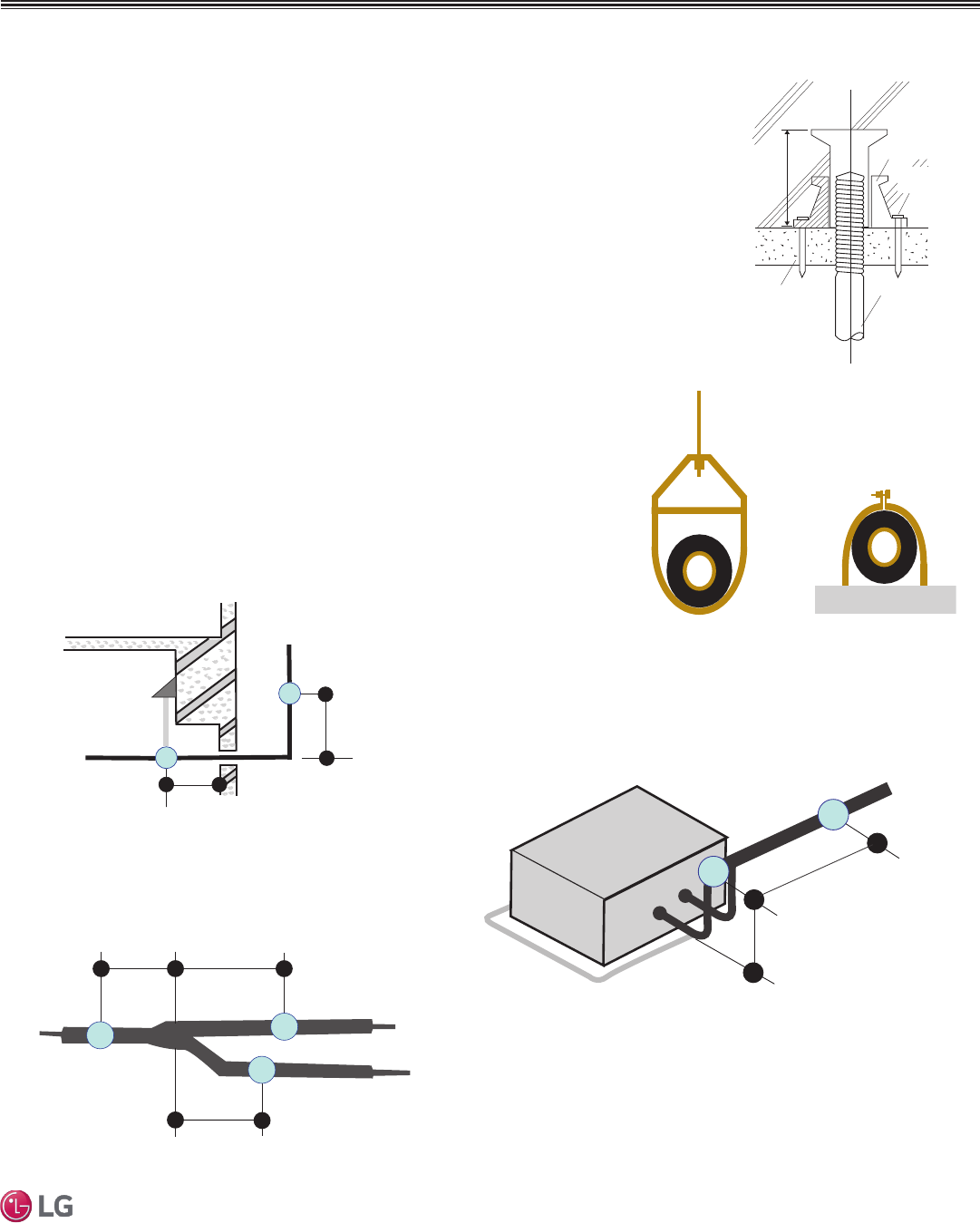

Figure 19: Installing an Insert Into

a Concrete Beam.

GENERAL INSTALLATION GUIDELINES

Refrigerant Piping

Inserts and Pipe Supports

Inserts

An insert can be installed into a floor or beam before the concrete sets so that fittings such as ducts,

pipes, or suspension bolts can be added at a later time. Decide where the inserts should be placed

before support installation.

Concrete Beam

Insert

Suspension Bolt

Anti-vibration Material

Nail

Figure 20: Pipe Hanger Details.

A

B

A + B ~ 12" – 19"

Max. 12" Max. 12"

Max. 12"

Figure 21: Typical Pipe Support Location—Change

in Pipe Direction.

Max. 12"

~ 12" – 19"

Pipe supports should never touch the pipe wall; supports should be installed outside

(around) the primary pipe insulation jacket. Insulate the pipe before installing the sup-

ports. Pipe supports are field-provided and must meet local code. If local codes do not

specify pipe support spacing, install pipe supports a maximum of 5 feet on center for

straight segments of pipe up to 3/4” outside diameter size.

Wherever the pipe changes direction, place a hanger within twelve (12) inches on one

side and within twelve to nineteen (12 to 19) inches of the bend on the other side. Sup-

port piping at indoor units as shown. Support Y-Branch fittings as shown.

Note:

The pipe system must be adequately supported to avoid pipe sagging. Sagging pipes become oil traps that

lead to equipment malfunction.

Figure 22: Pipe Support at Indoor Unit.

Figure 23: Pipe Support at Y-branch Fitting.