User guide

19.0 MICRO SERIES PID SET POINT CONTROL

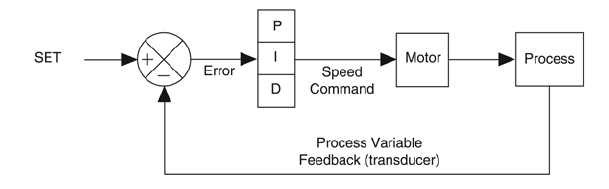

PID Set point Control allows the MICRO Series Control to maintain a process set point, such as PSI

orCFM,without usinganexternal controller.WhenPID isactivated,the MICRO SeriesControl will

operateinaclosed-loopfashion,automaticallyadjustingthemotorspeedtomaintainthesetpoint.

PIDsetpointcontrolrequiresfeedbackfromtheprocessinordertocomparetheprocessvariable“value”to

thesetpoint.Thedifferencebetweentheprocessvariable“value”andthesetpointiscalledtheerror.The

MICROSeriesControlwillincreaseordecreasethemotorspeedinanattempttominimizetheerror.By

constantlyadjustingthemotorspeed,thePIDcontrolwilldrivetheprocesstowardthesetpoint.Referto

thePIDblockdiagrambelow:

19.1 FEEDBACK DEVICES

AtransducerortransmitterisrequiredtomonitortheprocessvariableandprovidefeedbacktothePID

unit in order to compare the process variable feedback to the set point. A transducer outputs a signal

correspondingtoafixedrangeoftheprocessvariable.Atransmitterprovidesoffsetandgainadjustments

toallowtheoutputsignaltobeadjustedtocorrespondtodifferentrangesoftheprocessvariable.Typical

outputsignalsfortransducersandtransmittersare:0-5VDC,0-10VDC,or4-20mA.Thefeedbackdevice

mustbeexternallypowered,asthedrivedoesnothaveapowersupplyforsuchdevices.ProgramParameter

74-PIDFB(PIDFEEDBACKSOURCE)fortheappropriateterminal(TB-5AorTB-5B),andconnect

thefeedbackdeviceasdescribedbelow:

POT The positive signal wire (wiper) is connected to TB-5A, and the “high” lead is

connected to TB-6.

0-5, 0-10 VDC Connect the positive signal wire to TB-5A.

4-20 mA Connect the positive signal wire to TB-5B.

Thecommon,ornegativesignalwire,isconnectedtoTB-2(circuitcommon).

Feedbackdevicescan bedirectorreverseacting.Adirectactingdeviceoutputsasignalthatincreasesas

the process variable increases. A reverse acting device outputs a signal that decreases as the process variable

increases. The programming of Parameters 75 - FB @ MIN and 76 - FB @ MAX depend on the type of

feedbackdevicebeingused.

When using a direct acting transducer, Parameter 75 - FB @ MIN should be set to the value of the process

variablefeedbackcorrespondingtotheminimumfeedbacksignal(0VDCor4mA),andParameter76-FB

@MAXshouldbesettothevalueoftheprocessvariablefeedbackcorrespondingtothemaximumfeedback

signal(5or10VDC,or20mA).

Example 1: A 0-100 psi transducer outputs a 4 mA signal at 0 psi and 20 mA at 100 psi. Program Parameter

75 to 0.0 PSI, and Parameter 76 to 100.0 PSI (This assumes that Parameter 31 - UNITS is set to pid PSI,

andParameter33-UNITSDPissettoXXX.X).

77