User guide

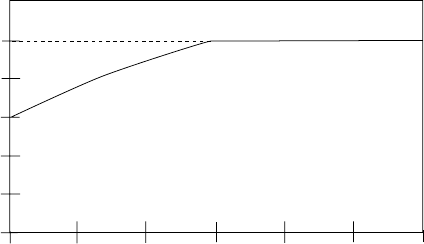

The“speed-compensated”thermaloverloadcircuitoffersadditionalprotectionfromhighloadconditions

atlowspeeds,wheremotorcoolingisoftenlesseffective(e.g.,motorswithshaft-mountedfans).Asseenon

thediagrambelow,thedrivereducestheallowablecontinuousoutputcurrentwhenoperatingatfrequencies

lessthan30Hz.

Example 2:A480Vac,20HPdriveisoperatingamotorat10Hz.Fromthediagram,adriveoperatingat

10Hzcandeliverabout75%ofitsoutputcurrentratingcontinuously.A480Vac,20HPdrive’soutput

current rating is 27 Amps. Therefore, the drive would be able to operate continuously at 20 Amps. The

drivewouldalsobeabletodeliver150%ofthatvalue(30Amps)foroneminutebeforetrippingintoan

OVERLOAD fault.

The“speedcompensated”thermaloverloadisthefactorydefaultandshouldbeusedinapplicationswhere

themotordoesnotnormallyexperiencehighloadsatlowspeedsforextendedperiodsoftime.

NOTE 1: The above diagram is based on a MOTOR OL setting of 100%. For lower MOTOR OL settings,

reducethe%CURRENTvaluesbythesamepercentage.Forexample,ifMOTOROLissetto75%,reduce

the % CURRENT values by 25%. Therefore, the curve shifts down, but the shape of the curve remains the

same.

The“non-compensated” thermal overloadcircuitallows 100% current continuously,and150% current

for one minute, at all speeds. In the example above, the motor operating at 10 Hz without

“speed-compensated”protectionwouldbeallowed tooperatecontinuouslyat27 Amps,andcoulddraw

40.5 Amps for one minute before tripping. Without sufficient motor cooling, this can result in motor

failure due to overheating.

The “non-compensated” circuit is selected by setting Parameter 22 - TORQUE to CT/NOCMP. The

“non-compensated”settingshouldonlybeusedinapplicationswherethemotorisproperlycooledatall

speeds, or the motor manufacturer has approved the motor for full-load operation at low speeds.

NOTE 2: The operation of the motor thermal overload circuit is affected by the setting of Parameter 34 -

LOAD MLT.

57

NON-COMPENSATED

SPEED COMPENSATED

100

80

60

40

20

10 20 30 40

50

60

FREQUENCY (Hz)

MAXIMUM CONTINUOUS

OUTPUT CURRENT (%)