Satellite TV System User Manual

5-5

Maintenance

54-0157 Rev. C

5.4.1 PCB Removal and Replacement

Estimated Time to Repair:

1

⁄2 hour

The microprocessor PCB assembly is protected by a cover

fastened to the rotating plate – Fig. 5-1. The cover must be

removed to gain access to the main power fuse and the PCB

assembly.

1. Remove the quick release pin from the pivot

bracket – Fig. 5-2.

2. Remove the elevation axis motor shaft from the

linear actuator – Fig. 5-2.

3. Remove the 6 pan head screws from the PCB cover

flanges. Remove the PCB cover – Fig. 5-1.

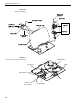

4. Remove cable connectors from PCB. Figure 5-5

illustrates the PCB arrangement and connector

locations.

5. The PCB is mounted to the rotating plate with

9 pan head screws. Remove the screws and PCB.

6. Reverse this process to install the replacement

PCB. Reinstall all cable connectors removed in

Step 4.

7. Carry out all calibration procedures for the

antenna gyro (Section 5.4.3).

8. Reinstall your preferred satellites as detailed in

Section 2.4.1, Installing Your Selected Satellites.

RF Board

PCB

J3

J1

RF Connector to IRD

RF Connector to LNB

Fuse

J5

J11

J9

J2 J1

J4

Gyro

RF Board

Limit Switches

Cable Wrap

Elevation Motor Azimuth Motor

TracVision L3 is equipped with a

5x220 mm, 4-amp, 250 volt fast-

blow fuse, which is mounted on the

PCB. To access and replace the

fuse, follow the directions to remove

the PCB cover and then swap the

blown fuse for a new one.

When carrying out maintenance

on the PCB, be sure to not drop

any of the small screws inside the

mechanism. If a screw is lost within

the baseplate, it must be retrieved

to avoid causing any damage when

the unit rotates.

Figure 5-5

PCB and RF Detector Board

Connector Locations