User's Manual

Table Of Contents

- Contents

- 1. Introduction

- 1.1 Features

- 1.2 Installation Guide

- 1.3 Accessories

- 2. Installation

- 2.1 Unpacking

- 2.2 Driver Installation

- 2.3 Hardware Installation

- 2.4 Device Setup & Configuration

- 2.5 Device Testing

- 3. Signal Connections

- 3.1 Overview

- 3.2 I/O Connector

- 3.3 Analog Input Connections

- 3.4 Analog Output Connections

- 3.5 Field Wiring Considerations

- 4. Software Overview

- 4.1 Programming Choices

- 4.2 DLL Driver Programming Roadmap

- 5. Principles of Operation

- 5.1 Analog Input Features

- 5.2 Analog Output Features

- 5.3 Digital I/O Features

- 5.4 Counter/Timer Features

- 6. Calibration

- 6.1 VR Assignment

- 6.2 A/D Calibration

- 6.3 D/A Calibration

- 6.4 Calibration Utility

- Appendix A. Specification

- Appendix B. Block Diagram

- Appendix C. Screw-terminal Board

- C. 1 Introduction

- C. 2 Features

- C. 3 Board Layout

- C.4 Pin Assignment

- C.5 Single-ended Connections

- C.6 Differential Connections

- Appendix D. Register Structure and Format

- D.1 Overview

- D.2 I/O Port Address Map

- D.3 A/D Single Value Acquisition - Write BASE+0

- D.4 Channel and A/D data - Read BASE + 0

- D.5 A/D Channel Range Setting - Write BASE+2

- D.6 MUX Control - Write BASE+4

- D.7 A/D Control/Status Register - Write/Read BASE+6

- D.8 Clear interrupt and FIFO - Write BASE+8

- D. 9 Interrupt and FIFO status - Read BASE+8

- D.10 D/A control/status register - Write/Read BASE+A

- D.11 D/A Channel 0/1 Data - Write BASE+C/E

- D.12 82C54 Counter Chip 0 - Write/Read BASE+10 to 16

- D.13 82C54 counter chip 1 - Write/Read BASE+18 to 1E

- D.14 Counter gate and clock control/status - Write/ Read BASE+20 to 26

- D.15 Digital I/O registers - Write/Read BASE+28

- D.16 Digital I/O configuration registers - Write/Read BASE+2A

- D.17 Calibration command registers - Write BASE+2C

- D.18 D/A Channel Data for Continuous Output Operation Mode - Write BASE+30

- Figures

- Figure 2-1: The Setup Screen of Advantech Automation Software

- Figure 2-2: Different options for Driver Setup

- Figure 2-3: The device name listed on the Device Manager

- Figure 2-4: The Advantech Device Installation utility program

- Figure 2-5: The I/O Device Installation dialog box

- Figure 2-6: The "Device(s) Found" dialog box

- Figure 2-7: The Device Setting dialog box

- Figure 2-8: The Device Name appearing on the list of devices box

- Figure 2-9: Analog Input tab on the Device Test dialog box

- Figure 2-10: Analog Input tab on the Device Test dialog box

- Figure 2-11: Analog Output tab on the Device Test dialog box

- Figure 2-12: Digital Input tab on the Device Test dialog box

- Figure 2-13: Digital Output tab on the Device Test dialog box

- Figure 2-14: Digital output tab on the Device Test dialog box

- Figure 3-1: I/O connector pin assignments for the PCI-1712/1712L

- Figure 3-2: Single-ended input channel connection

- Figure 3-3: Differential input channel connection - ground reference signal source

- Figure 3-4: Differential input channel connection - floating signal source

- Figure 3-5: Analog output connections

- Figure 5-1: Post-Trigger Acquisition Mode

- Figure 5-2: Delay-Trigger Acquisition Mode

- Figure 5-3: About-Trigger Acquisition Mode

- Figure 5-4: Pre-Trigger Acquisition Mode

- Figure 5-5: PCI-1712/1712L Sample Clock Source

- Figure 5-6: Frequency measurement

- Figure 6-1: PCI-1712/1712L VR1 & TP5

- Figure 6-2: Selecting the device you want to calibrate

- Figure 6-3: Warning message before start calibration

- Figure 6-4: Auto A/D Calibration Dialog Box

- Figure 6-5: A/D Calibration Procedure 1

- Figure 6-6: A/D Calibration Procedure 2

- Figure 6-7: A/D Calibration Procedure 3

- Figure 6-8: A/D Calibration is finished

- Figure 6-9: Range Selection in D/A Calibration

- Figure 6-10: Calibrating D/A Channel 0

- Figure 6-11: Calibrating D/A Channel 1

- Figure 6-12: D/A Calibration is finished

- Figure 6-13: Selecting Input Rage in Manual A/D Calibration panel

- Figure 6-14: Adjusting registers

- Figure 6-15: Selecting D/A Range and

- Figure 6-16: Selecting D/A Range and Choosing Output Voltage

- Figure 6-17: Adjusting registers

- Figure C-1: PCLD-8712 board layout

- Figure C-2: CN2 pin assignments for the PCLD-8712

- Tables

- Table 3-1: I/O Connector Signal Description (Part 1)

- Table 3-1: I/O Connector Signal Description (Part 2)

- Table 3-1: I/O Connector Signal Description (Part 3)

- Table 5-1: Gains and Analog Input Range

- Table 5-2: Analog Input Data Format

- Table 5-3: The corresponding Full Scale values for various Input Voltage Ranges

- Table 5-4: Analog Output Data Format

- Table 5-5: The corresponding Full Scale values for various Output Voltage Ranges

- Table D-1: PCI-1712/1712L register format (Part 1)

- Table D-1: PCI-1712/1712L register format (Part 2)

- Table D-1: PCI-1712/1712L register format (Part 3)

- Table D-2: Register for channel number and A/D data

- Table D-3: Register for A/D channel range setting

- Table D-4: Gain Codes for the PCI-1712/1712L

- Table D-5: Register for multiplexer control

- Table D-6: Register for A/D control/status

- Table D-7: Analog Input Acquisition Mode

- Table D-8: Register for clear interrupt and FIFO

- Table D-9: Register for interrupt and FIFO status

- Table D-10: Register for D/A control

- Table D-11: Analog output operation mode

- Table D-12: Register for D/A channel 0/1 data

- Table D-13: Register for 82C54 counter chip 0

- Table D-14: Register for 82C54 counter chip 1

- Table D-15: Register for counter gate and clock control/status

- Table D-16 : Table of Cn1 to Cn0 register

- Table D-17: Table of Gn1 to Gn0 register

- Table D-18: Table for CLK_SEL1 to CLK_SEL0 register

- Table D-19: Register for Digital I/O

- Table D-20: Register for digital I/O configuration

- Table D-21: Register for digital I/O configuration

- Table D-22: Register for calibration command

- Table D-23: Calibration command

- Table D-24: Register for D/A channel data

– 83 –

APPENDIX D

PCI-1712/1712L User’s Manual

Advantech Co., Ltd.

www.advantech.com

D.3 A/D Single Value Acquisition Write BASE+0

The A/D converter will convert one sample when you write to the

register Write BASE+0 with any value. User can check the A/D FIFO

status (A/D_F/E on register Read BASE+8) to make sure if the data is

ready to be received.

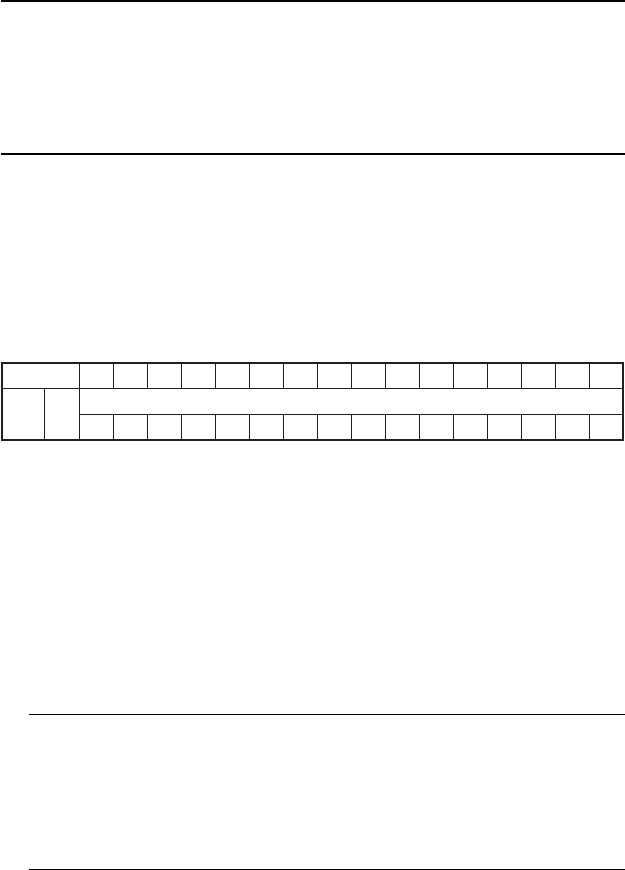

D.4 Channel and A/D data Read BASE + 0

These two bytes in Read BASE+0 hold the result of A/D conversion

data.

The 12 bits of data from the A/D conversion are stored in bit 0 to bit

11, bit 12 to 14 hold the A/D channel number and bit 15 holds the

trigger event flag.

Table D-2: Register for channel number and A/D data

AD11 TO AD0 Data of A/D Conversion

AD0 the least significant bit (LSB) of A/D data.

AD11 the most significant bit (MSB) of A/D data.

CH2 to CH0 A/D Channel Number

CH2 ~ CH0 hold the A/D channel number from which the data is

received.

CH2 MSB.

CH0 LSB.

Note:

✎ A/D channel number specifies the channel from which data is derived.

CH2 is the MSB and CH0 is the LSB. For channel scan, there should

have 4 channel codes, specifically from CH0 to CH3. Because we have

not enough address space, bit 15 is used for other purposes instead for

CH3, which is hence not available..

AF A/D trigger event flag

The trigger flag indicates whether a trigger event has happened during

A/D conversion process.

.ddAesaB 51 41 31 21 11 01 9 8 7 6 5 4 3 2 1 0

0 R

atadD/AdnalennahC

FA 2HC 1HC 0HC 11DA 01DA 9DA 8DA 7DA 6DA 5DA 4DA 3DA 2DA 1DA 0DA