Product Manual

30in. W Capacity 3-in-1 Combination

Sheet Metal Machine

OWNER’S MANUAL

30in. W Capacity 3-in-1 Combination

Sheet Metal Machine

OWNER’S MANUAL

After Each Use

• When the machine will not be used for a while, remove any debris or scraps of metal, clean it,

and spread a thin coat of oil on the unpainted surfaces to prevent rust.

• Grease the crank arms (4) as necessary using a grease gun on the installed grease fittings.

Do not over-grease.

• A light coating of oil on the area where the upper arm slides will also assure ease of

movement.

Maintenance

Maintain your machine. It is recommended that the general condition of any tool be examined

before it is used. Keep your tool in good repair by adopting a program of conscientious repair

and maintenance in accordance with the recommended procedures found in this manual.

• Keep all cutting tools sharp and clean. Properly maintained cutting tools with sharp cutting

edges are less likely to bind and are easier to control.

• Keep handles dry, clean, and free from oil and grease.

• Use only replacement parts that are recommended by the manufacturer for use with this

machine.

• The parts of this machine which are ground should be coated with a light film of oil .A very

light film of oil on the slip rolls will inhibit rust.

The shear blades (13, 23) are interchangeable. The 5 relief is always the upper blade cutting

edge. The lower blade cutting edge has no relief and the blade is installed with the 5 relief

against the table edge.

LUBRICATION

Grease should be kept on the roll gears on the end of the rolls (12 - 23).

Grease the surface between the shear blade support and the back spacer bar.

Grease the shear support beam bolt on the front side of the shear support beam.

Grease the bolts and plug on the shear material pressing plate (10)

6 of 10 7 of 10

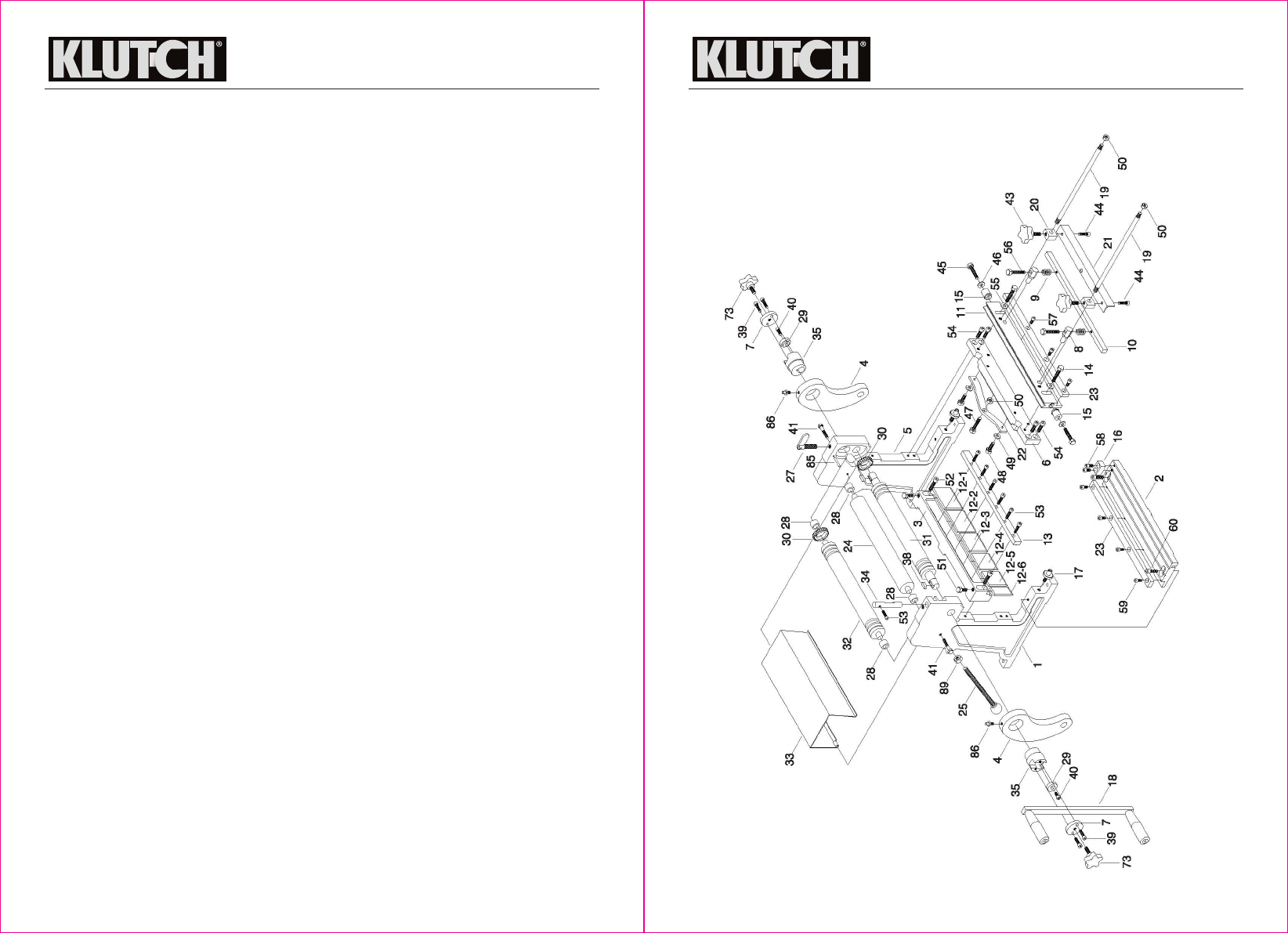

Parts Diagram