Product Manual

12in. W Capacity 3-in-1 Combination

Sheet Metal Machine OWNER’S MANUAL

12in. W Capacity 3-in-1 Combination

Sheet Metal Machine OWNER’S MANUAL

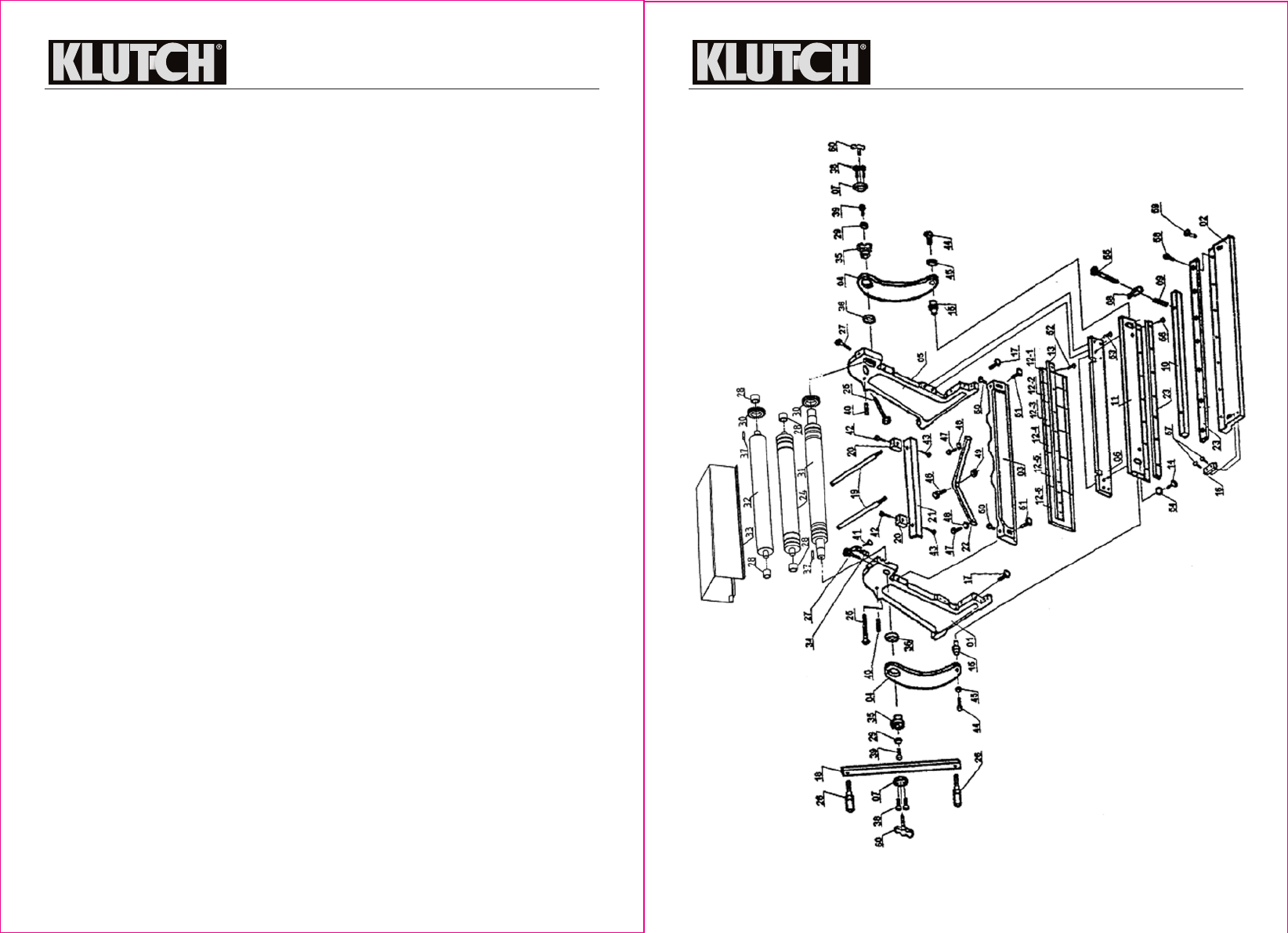

Parts Diagram

4 of 8

Braking

1. Attach the backmeasurement assembly(19-21,42,43) to the receiver holes in the back of the

crossbeam(3).

2. If necessary, adjust the position of the back measurement assembly: first loose the two hex

key screws (42), movethe assembly forward and back to the desired position, retighten the

screws.

3. Using the handle assembly (18&26), raise the crossbeam(3) up to its highest position.

4. Insert the workpiece between the upper (12) and lower(11) braking dies.

5. Turn the handle assembly (18&26) until the proper roll has been achieved. The materialshould

feed itself through the rollers as you crank the handle assembly.

Rolling

1. Lift the front Cover (33) and flip backward, out of the way.

2. Drop the Rear Roll Bar (24) by loosening the Adjustment Knob (25).

3. Insert only the leading edge of the sheet metal between the Upper Roll Bar (32) andthe Lower

Roll Bar (31), tighten the Adjustment Keys (27) until the Roll Bars are justsnug against the

sheet metal.

4. Advance the Adjustable Bolt (25) to the desired tightness for the roll.The more the Adjustable

Bolt (25) is advanced, the tighter the roll.

5. Turn the Handle Arm (18) until the desired roll is achieved.

The sheet metal should feed itself through the rollers as the Handle Arm (18) is turned

Wire Rolling

1. Use the proper groove in the lower roll bar (#24、#31) depending upon the gauge of the wire

beingrolled.

2. Follow steps 2 through 5 (above), under Rolling.

After Each Use

• Clean the surface of the Roll Bar (24, 31, 32) after use. Keep it clean and free of rust.

• Check Dies (12) and Shears (23)not damaged after use.

• Grease the crank arms(4) as necessary using agrease gun on the installed grease fittings. Do

notover-grease.

•

A light coating of oil on the area where the upperarm slides will also assure ease of movement.

Maintenance

Maintain your tool. It is recommended that the general condition of any tool be examined before

it is used. Keep your tool in good repair by adopting a program of conscientious repair and

maintenance in accordance with the recommended procedures found in this manual.

• Keep all cutting components sharp and clean. Properly maintained cutting components with

sharp cutting edges are less likely to bind and are easier to control.

• Keep handles dry, clean, and free from oil and grease.

• REPLACEMENT PARTS AND ACCESSORIES. When servicing, use only identicalreplacement

parts. Parts that may be suitable for one machine may create a risk of injury when used with

another machine. Approvedaccessories are available from the distributor.

LUBRICATION

• Before using this machine, certain parts coated with rust inhibitor must be first cleanedusing

varnish thinner.

• Lubricate the eccentric mechanism daily with machine oil.

• Periodically check all nuts, bolts, and screws for tightness.

• Periodically lubricate the rollers surface with a clean rag and machine oil.

• Place the Cover over the rollers when not in use

• Grease the cranking arms(4) as necessary using a grease gun with zerk fittings.

• Grease the bolt holes in sliding areas after take down the Hex key screw(14&51) as

necessary.

5 of 8