User Manual

D03Rev2.3

18

DMT proprietary & confidential: product information is subject to change without notice.

Domintech Co., Ltd. Tel: +886-2-2290-1288 Fax: +886-2-2290-1266 http://www.domintech.com.tw

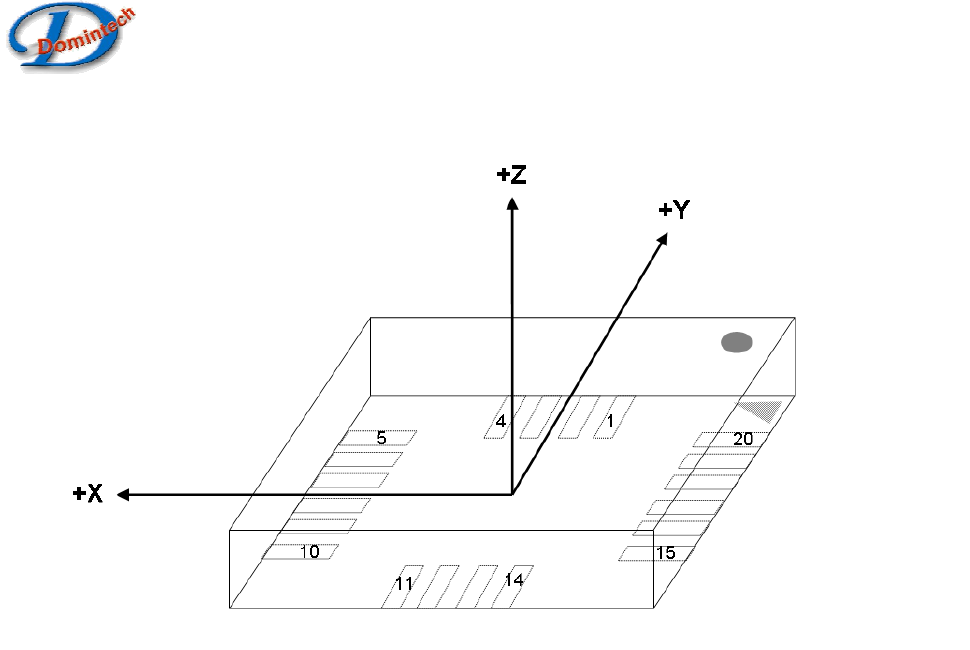

Axes Orientation

Figure 12: Axes Orientation of DMARD03

RoHS Compliance

The 20-pin LGA package conforms to the EU directive on the restriction of the use of certain

hazardous substances in electrical and electronic equipment 2002/95/EC.

Surface Mounting Information

The accelerometer is sensitive to the mechanical and thermal stress, so proper PCB board design and

well-executed soldering processes are crucial to ensure consistent performance. Below summarized

the guidelines for the surface mounting technology:

1. The layout dimension of the PCB land pad and SR open should follow the recommendation in

Figure 13.

2. The placement of accelerometer should not be within the vicinity of mechanical screws, fasteners,

fixtures, and etc. The kept distance is to diminish the mechanical stress influence.

3. The area underneath the accelerometer package should be clear of any top copper traces and

any structure like via. It is to ensure the planarity and reduce the potential board stress.

4. The trace connected to the land pad should be as symmetric as possible.

5. Do not place any components, buttons, shielding case or via at a distance less than 2mm from

the accelerometer package land area. This is to prevent mechanical stress or large thermal

sink/source to the adverse of sensor performance.

6. Use a typical pick-and-place machine with reflow equipment like oven. Avoid any manual

soldering process.

7. We recommend using a no-clean solder paste for the surface mounting process. Figure 14

should be referred for proper soldering temperature profile control.

8. Offset shift may exist after the accelerometer being mounted onto the PCB board. It depends on