User's Manual

Component Descriptions

September 2013 2-32 P/N 81-CO2MAN-001

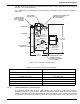

regular pneumatic control head except that its detection chamber has no vent. Thus, all the

compensation for normal environmental pressure changes is performed by the vented

pneumatic control head. The diaphragm pressure setting of the tandem control head is chosen

to match that of its corresponding vented pneumatic control head. The two diaphragm

chambers are interconnected via 3/16-inch copper tubing. If the system is to be actuated

remotely via a pull box and cable, the manual cable control is connected to both the pneumatic

and tandem control heads.

Figure 2-36. Tandem Pneumatic Control Head

2-3.6 Components for Pneumatic Actuation Systems

Pneumatic (rate-of-rise) systems utilize a variety of specialized components to control the

actuation of a carbon dioxide suppression system.

2-3.6.1 PNEUMATIC CABLE HOUSING

A pneumatic cable housing (Figure 2-37) is required when a pneumatic control head and a

tandem control head are installed for simultaneous actuation by a remote pull box and cable.

The housing protects the interconnecting cable between the two pneumatically-operated

control heads and to secure the heads in a fixed position. The length of the cable housing (see

Table 2-12) is determined by the size of the cylinders used in the suppression system.

16

1"

3/16 in. x 17 in. LONG

COPPER TUBING

P/N WK-802366-000

CABLE BLOCK

PRIMARY PNEUMATIC

CONTROL HEAD (VENTED)

CYLINDER CENTERS

CABLE HOUSING

TANDEM PNEUMATIC

CONTROL HEAD

3/8 in. PIPE OR

ALTERNATE ASSEMBLY

CABLE

3/16 in. COPPER TUBING

CONNECTION

3/16 in. TUBING TEE (SUPPLIED

WITH TANDEM CONTROL HEAD)